SendCutSend’s plasma cutting service is entirely online – just upload your CAD file, get an instant price, and then order to get your parts in a matter of days. With low minimums and fast service, there’s no need to find a plasma cutting service close to you – we can have parts at your door quickly.

Plasma cutting only works with conductive metals, which significantly reduces the options available for your project. And even then, there are certain conductive materials, like aluminum, that are too soft to guarantee a precise cut because the plasma will melt it. Need a metal, plastic or composite that needs laser cutting or CNC routing? Don’t worry! We do those too!

Plasma cutting works well for certain types of projects. For example, if you need bevel cuts on your part for eventual welding purposes, plasma cutting can make that happen. However, plasma is slower, less accurate, and more dangerous than laser cutting.

Laser cutting can perform highly intricate cuts with tight tolerances, and is faster than plasma cutting by an order of magnitude when cutting thin metals. Plasma is faster at cutting medium thickness materials, around 1”, and therefore a bit more cost effective for thick metals than laser cutting. But here at SendCutSend, our waterjet easily takes care of all the thicker materials you may need, so you don’t have to worry about that either!

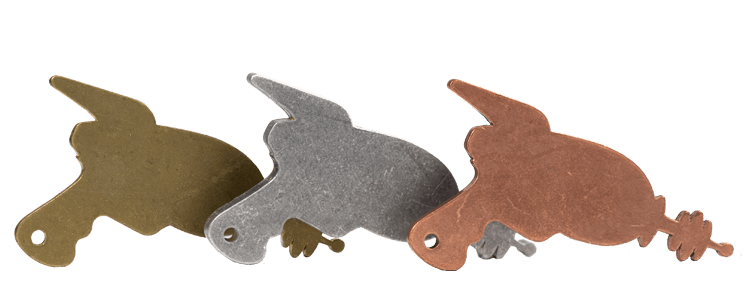

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

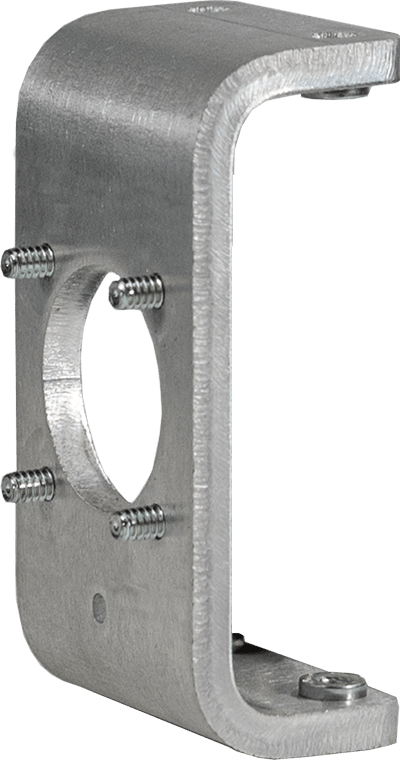

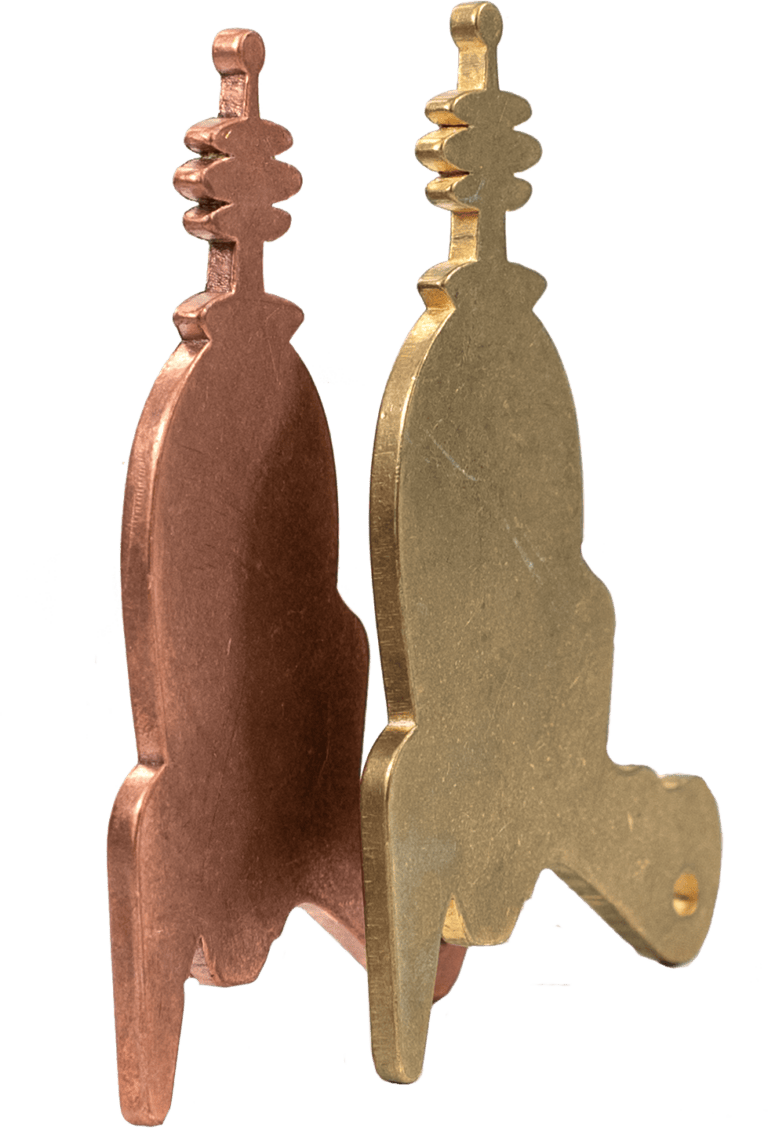

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

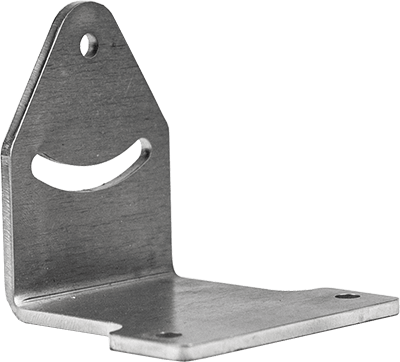

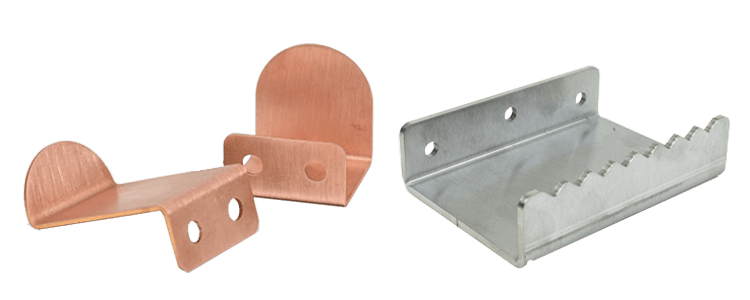

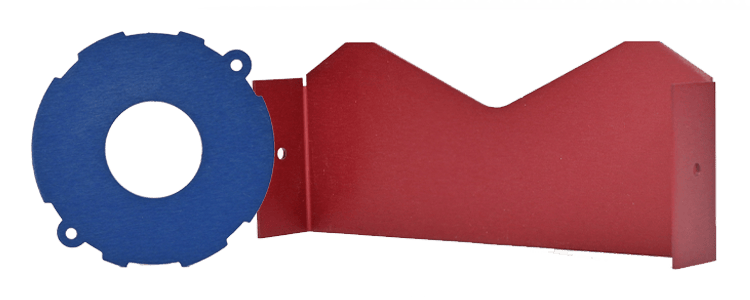

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

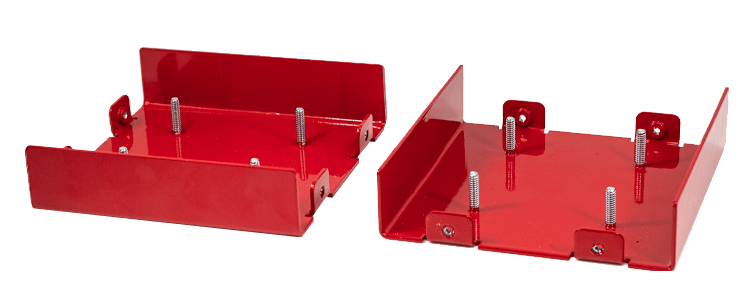

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

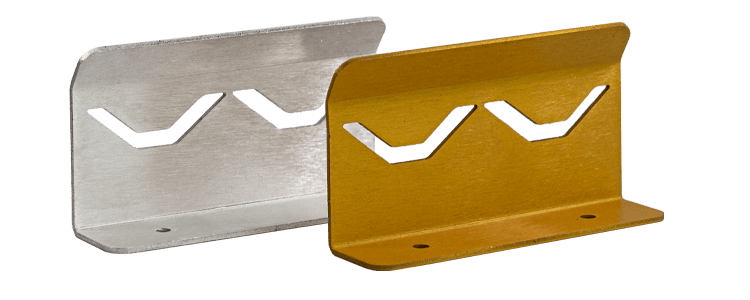

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

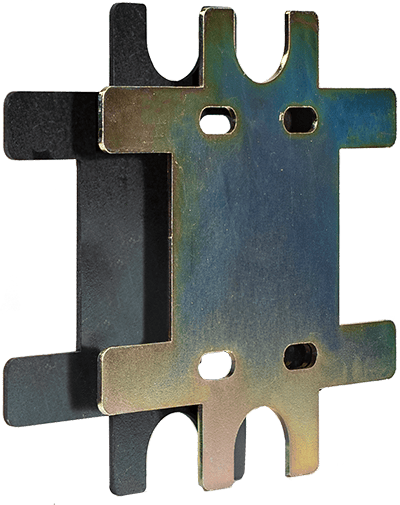

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials