Our polycarbonate (also known as Lexan®) is perfect for high-impact applications, instrument panel covers, insulation applications, and fittings. It’s an incredibly versatile, formable material, well-loved in the robotics and automation industries.

Instant quote

A: 1″ x 2″

B: 30″ x 44″

Custom quote

C: 30″ x 47″

.118″ (3.0mm)

.177″ (4.5mm)

.220″ (5.6mm)

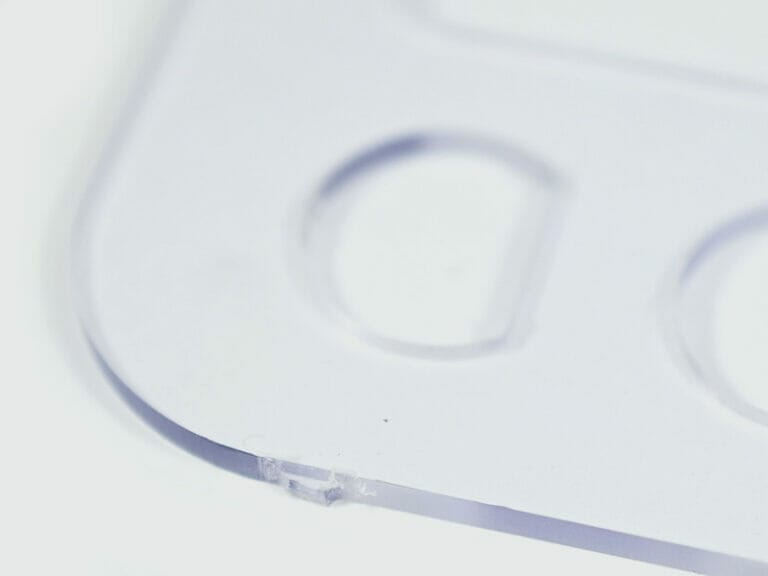

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

This impressively tough and transparent material can withstand high impact over a wide range of temperatures, has a high heat deflection temperature, and has a high modulus of elasticity, making it a great fit for construction applications such as windows, skylights, and roof domes. Of course, that’s only an extremely small view into what polycarbonate is capable of in the industry.

Polycarbonate / Lexan® material absorbs very little moisture and has high-voltage insulating properties. This makes it ideal for use in electrical and electronic components. Its transparency also makes it a superior option for structural applications that require healthy sightlines.

Polycarbonate is commonly used in anti-ballistic panels (aka bulletproof glass). If that doesn’t stand testament to its impact absorption, we’re not sure what else would. If you still need more convincing, it’s also got a lot of other great stuff:

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Polycarbonate in three thickness options: .118″ (3.0mm), .177″ (4.5mm), and .220″ (5.6mm).

SendCutSend offers Polycarbonate with clearly defined size and thickness options. For instant quoting, the smallest part size available is 1″ x 2″, while the largest part supported is 30″ x 44″. For larger projects, custom quotes are available for sizes up to 30″ x 47″.

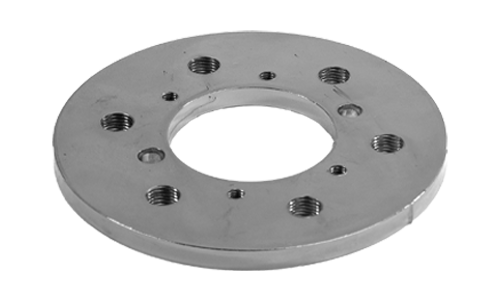

You can add the following services to your Polycarbonate parts:

Bending and Tapping