Our MDF material is a solid, comparative material to basic plywood and is almost indistinguishable in most applications. It’ll save you money on large runs of furniture production, panels for soundproofing, or even automotive usage by itself.

.125″ – .250″ Thickness

A: .25″ x .375″

C: 30″ x 44″

.375″ – .500″ Thickness

B: 1″ x 2″

C: 30″ x 44″

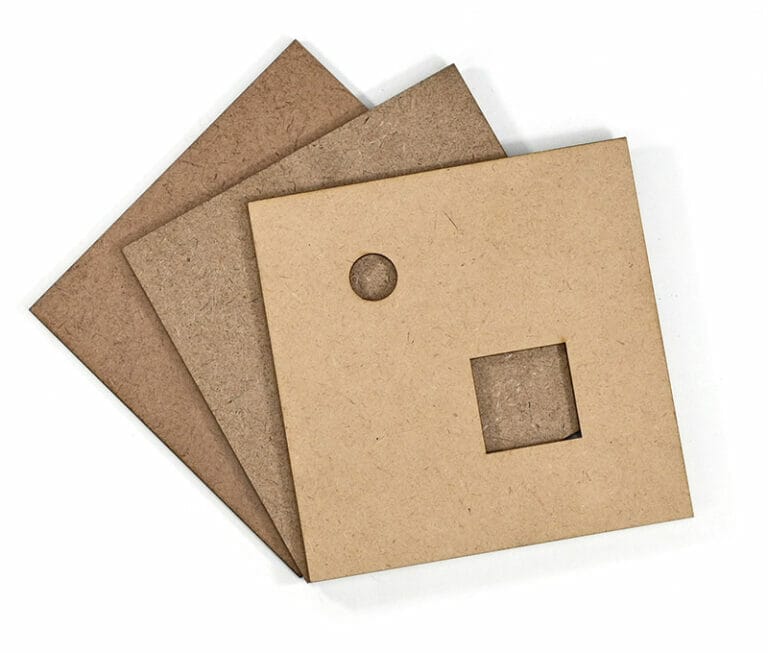

Due to ongoing global supply chain shortages, there will be variations in your custom cut MDF finish color and texture. Some variations of MDF may be darker and have a slight sheen, as shown in the images here. These darker variations will also have a dark cut edge and differing edge cut finish from our traditional MDF.

These finish variations will not alter the integrity of your parts in any way, but be aware that if you have multiple MDF parts in a single order, those parts may slightly vary in color and finish.

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

Our MDF, or Medium Density Fiberboard, is a unique composite wood material made from sawdust and fibers from both softwoods and hardwoods. These components are mixed with resin and then subjected to forming by extreme temperature and pressure, creating a spectacularly pliant and workable sheet material.

There’s a lot of information out there about real wood being superior to particleboard and MDF, but like with most projects, it really depends on what you need it for. The truth is MDF board functions about as well as, if not better than plywood for many project types. The key is knowing what you need from your board.

It should be noted that MDF is not ideal for external environments where it’d be subjected to the elements, as the material will warp and quickly fall apart. Although if you need a more accessible material for furniture, custom sound systems, or other indoor application, MDF will save you tons of cash in the long run and provide the same quality as a similar strength wood.

If you’re worried about off-gassing and potential liquid spillage ruining your finish, our MDF is treatable for a variety of purposes, such as fire resistance, liquid sealing, and different paints

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers MDF in four thickness option: .125″(3.18mm), .250″(6.35mm) , .375″ (9.50mm), and .500(12.7mm).

When ordering MDF parts through SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is .25″ x .375″, while the largest part supported is 30″ x 44″.

The following cutting methods are available for MDF parts:

CNC Routing or Laser Cutting