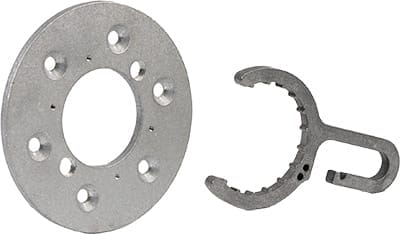

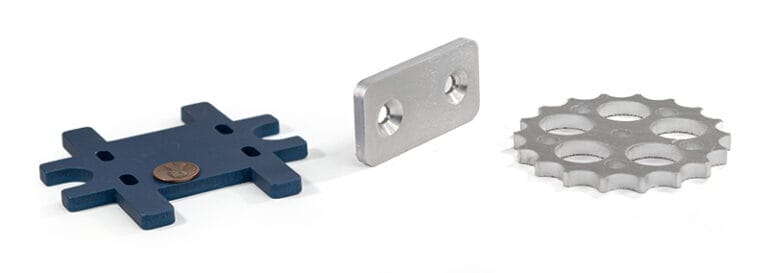

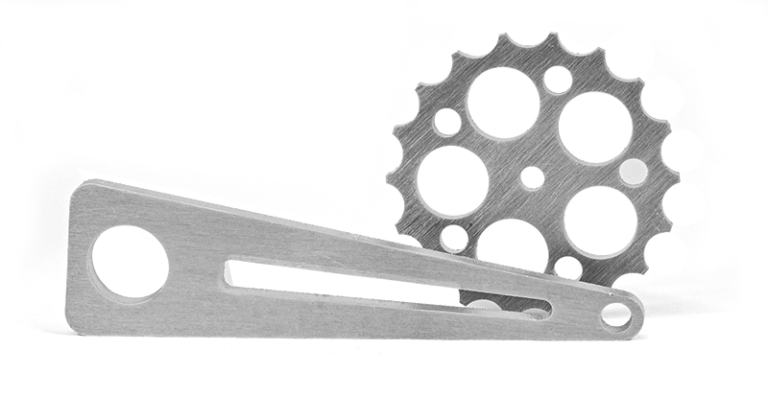

With nearly double the tensile strength and almost double the shear strength of 6061, our 7075 aluminum is laser cut or and is one of the best options available when high-strength and low-weight are important.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 47″

.125″ (3.18mm)

.190″ (4.83mm)

.250″ (6.35mm)

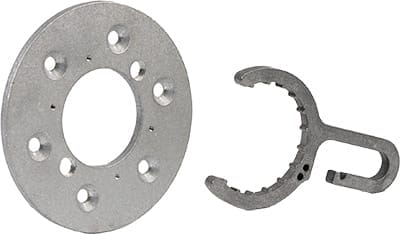

7075 Aluminum is our toughest and strongest aluminum alloy. Like 6061 aluminum, 7075 aluminum was made for use in the aerospace industry, where it’s used extensively. It’s lightweight and durable, so it also lends itself to bike frames, rock climbing equipment, and other high stress environments.

7075 sacrifices some of 5052 aluminum’s workability, formability, and weldability for increased hardness, strength, and overall toughness.

Still carrying the benefits of other aluminum alloys, such as lower weight and high fatigue strength, 7075 aluminum positions itself dominantly as having one of the best strength to weight ratios in any aluminum alloy.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

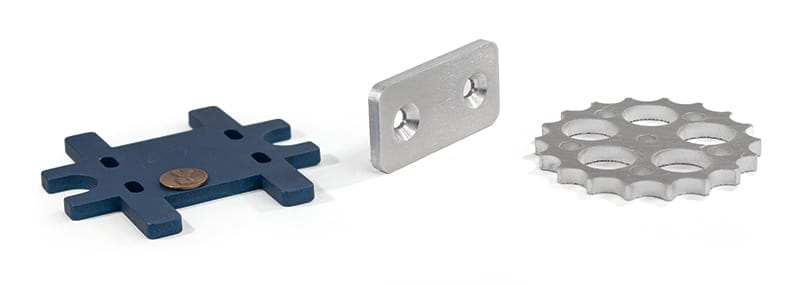

SendCutSend offers 7075 T6 Aluminum in three thickness options: .125″ (3.18mm), .190″ (4.83mm), and .250″ (6.35mm).

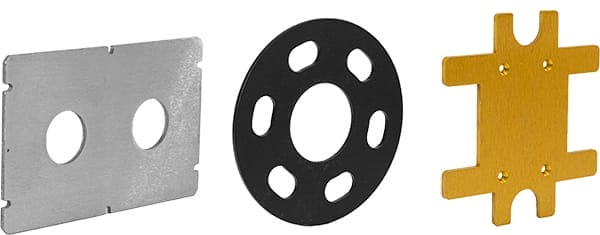

With SendCutSend’s 7075 T6 Aluminum offering, you can get parts instantly quoted if they fall between .25″ x .375″ and 30″ x 44″. Custom quotes are available for sizes up to 30″ x 56″.

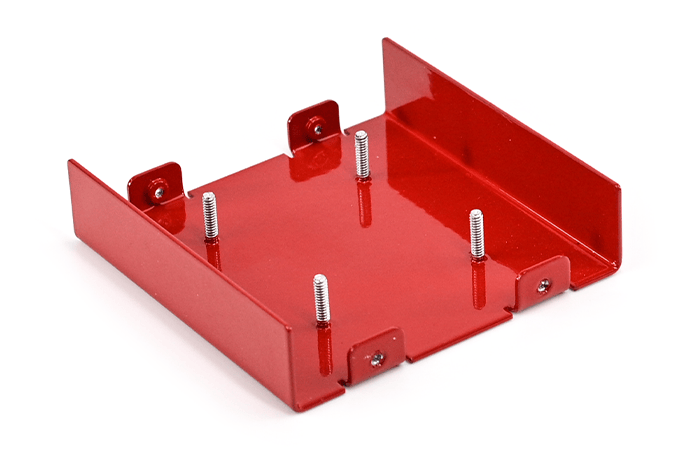

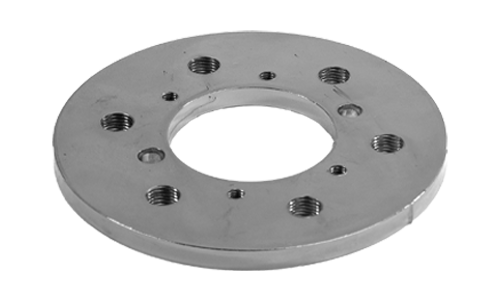

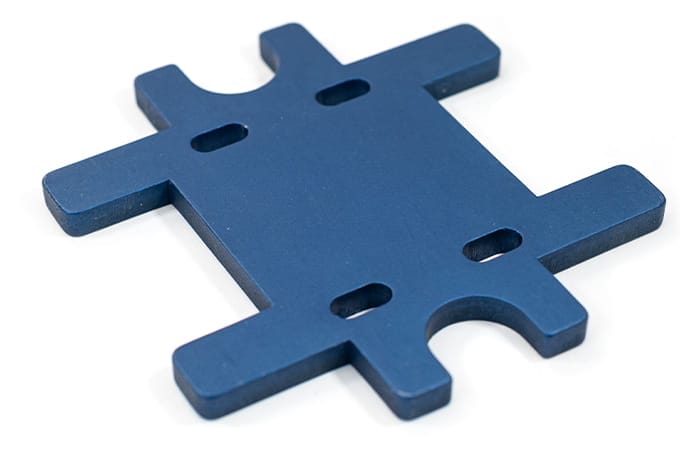

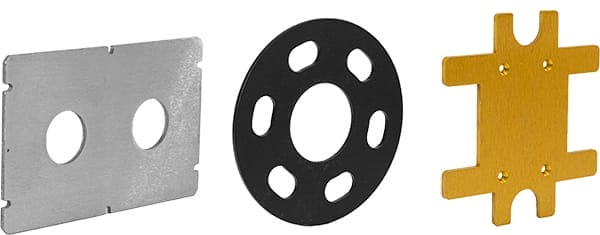

You can add the following services to your 7075 T6 Aluminum parts:

Anodizing, Countersinking, Deburring, Hardware Insertion, Powder Coating, Tapping, and Tumbling