Stainless steel has a lot going for it; product designers love its bright, classy appearance and fabricators appreciate how cleanly it welds. Yachtsmen enjoy its resistance to the elements, and rocket designers are drawn to its strength in both high and low temperatures.

This article will cover two of the most popular alloys of stainless steel that are carried by SendCutSend, 304 Stainless Steel and 316 Stainless Steel. Here’s what we’ll cover:

- The history and physical properties of stainless steel

- Details about how it is processed at SendCutSend

- Considerations for the home DIY’er

- Example applications a

- Insight about the cost/benefit balance when choosing 316 over 304.

History of Stainless Steel: From 18/8 to Modern Marvels

Stainless steel is a relatively new material. The development of modern stainless steel occurred in stages, starting in 1798 with the addition of chromium to regular carbon steel in France. T

hroughout the 1800s various alloys of chromium steel were used in everything from cutlery to bridges to cannon barrels. Nirosta, the earliest form of 304 stainless steel, was patented in 1914 in Sheffield, England. Modern SAE 304 stainless was developed in 1924 and was sold as “Staybrite 18/8.”

Type 304 is also known as 18/8 stainless, due to its composition of 18% chromium and 8% nickel. The 316 alloy is made by adding 2% molybdenum to 304 stainless, which improves its resistance to corrosion in saltwater and acidic environments.

All 300 series stainless is nonmagnetic, which makes it somewhat more challenging to hold during some operations such as welding and hardware insertion.

The Durability of Stainless Steel

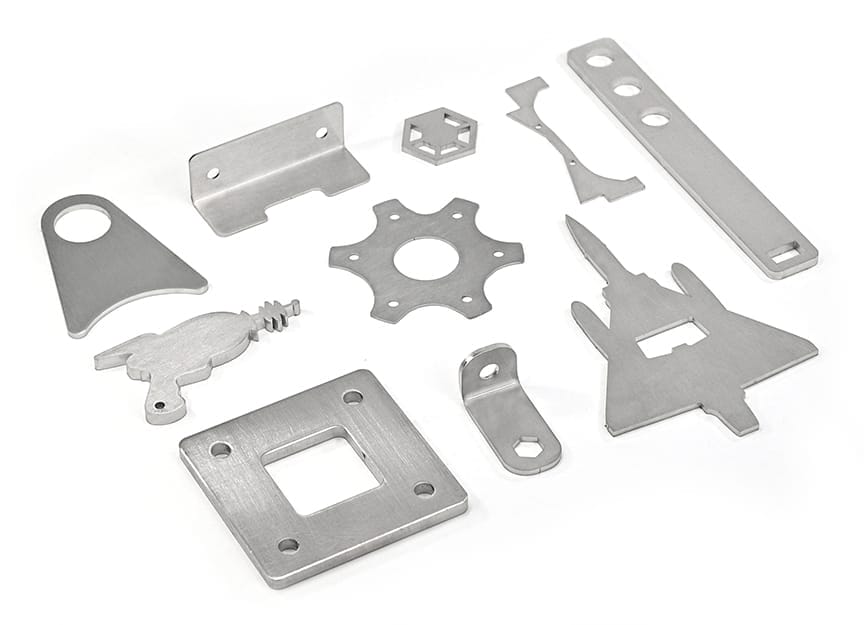

All stainless steel alloys are incredibly durable, both chemically and mechanically. This makes them highly suitable for high-wear environments and situations, like cookware, cutlery, and machine parts.

This same durability makes them notoriously difficult to work with at home, and SendCutSend is here to help with post processing operations such as tapping and hardware insertion. Many readers know the pain of a broken drill bit or tap, caused by stainless steel’s highly ductile, “gummy” nature. These types of headaches can bring a DIY project to a standstill.

You can avoid this frustration entirely, at a very reasonable cost by leaning on SendCutSend’s wide variety of value-added services. A laser cut hole or slot, is always preferred to a hole drilled in a nearly-finished part at home. From threaded inserts to tapping, threaded studs to standoffs, SendCutSend has you covered.

SendCutSend’s Laser Cutting Services on Stainless Steel

While on the topic of processing, here’s a note on laser cutting. There are several methods of laser cutting ferrous materials. The lower cost option involves a lower laser power and oxygen gas. The laser provides the initial heat, while compressed air and/or oxygen gas is added to the cut zone to increase temperature and intensify the cutting power. The cut edge is relatively dirty, and the heat affected zone is relatively large. A dark, scaly oxide layer is left on the cut edge, which must be removed prior to welding or coating.

The second method is considered to be superior, and involves a much higher laser power, faster cutting speed and nitrogen gas. The gas is pumped into the cut zone to make for an inert environment and corrosion-free cut. It’s sometimes referred to as a “white” edge in the industry. This method requires a more expensive laser cutting machine, and more expensive nitrogen gas, but produces much nicer parts. Thankfully all parts laser cut by SendCutSend are nitrogen cut with clean, bright edges and a very small heat affected zone.

Stainless Steel Welding: Techniques for Success

Stainless steel is a joy to weld. A TIG process produces zero spatter, and strong, beautiful welds are not difficult to create, even for the relative beginner. Each grade of stainless is available in a “H” or “L” variation, which corresponds to High and Low carbon content.

Standard- and high-carbon material is not recommended for welding, as the weld area becomes susceptible to corrosion. Thankfully, all stainless steel sold by SendCutSend is of the low carbon variety, and as such is ideal for welding.

When to Choose 304 Stainless Steel vs 316 Stainless Steel

A good rule of thumb with stainless weld rod, is to use a rod material that’s of an equal or higher grade than the parent material. So, 316 rod is great for both 304 and 316 steel, but 304 rod shouldn’t be used to weld 316 material. One must work hot and move fast, to provide good penetration and a minimal heat affected zone. Use a high enough flow rate of shield gas to keep the weld bright silver, and make sure to set post flow for long enough for the weld termination area to cool down.

304 Stainless Steel has been referred to as the workhorse of corrosion resistent steels and performs exceptionally well at high temperatures, and makes for a lovely sounding and long lasting exhaust system. Everything from the St Louis Arch to SpaceX rockets have been made with 304 stainless, and it’s all that’s needed for most applications. However, type 304 falls short in salty environments and that’s where 316 comes in.

There’s a rough 20% price penalty for specifying 316, but it’s exactly what’s needed in marine settings. Better to buy once and cry once! In short, if the application is not for the petroleum industry, surgical theater, marine world, or doesn’t involve chlorine or chloride salts, 304 is usually sufficient.

Final Thoughts: The Stainless Steel Advantage

Hopefully, this article has shed some light on the key differences between 304 Stainless Steel and 316 Stainless Steel, and some of the advantages and pitfalls of working with this material.

While the cost is higher than standard cold rolled steel, the advantages are many. With the wide variety of additional services and hardware available at the click of a mouse, the pain points of using this material are effectively eliminated.

There should be no hesitation in choosing SendCutSend for your next stainless steel project. If you’re ready to get started, upload your DXF or STEP file to sendcutsend.com for instant pricing.