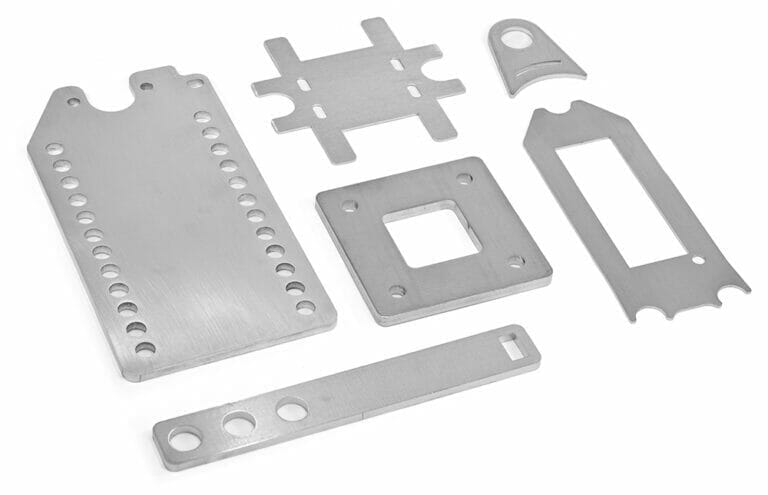

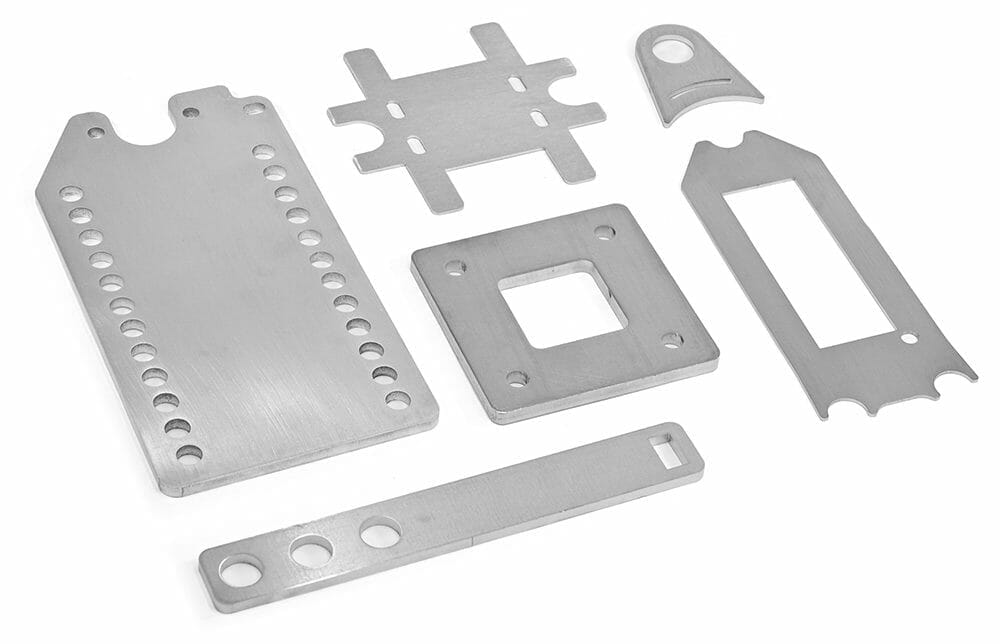

For when you need greater resistance to the elements than 304 can provide, 316 stainless steel is here to meet your needs. Stronger, more durable, and more resistant, laser cut 316 stainless steel will bring the muscle to your next outdoor project.

With high amounts of nickel and chromium and a lower carbon count than other stainless varieties, 316 is highly corrosion resistant. Able to remain corrosion resistant across many different environments makes this steel an important material in modern industries.

Our 316 stainless steel is very similar to 304 in application, but this material differs in one major area: corrosion resistance. By alloying molybdenum into its composition, 316 circumvents 304’s common pitfalls when it comes to rusting. Specifically, 316 is adept at resisting corrosion caused by chloride exposure. This means that it’s great for holding tanks that could come into contact with corrosive liquids, such as sea water, or chlorine.

SendCutSend’s laser cut 316 stainless steel will live up to your highest expectations regarding strength and corrosion resistance. While it’s not as easy to machine as 304 stainless steel, it makes up for that in the durability it will bring to your next project. And machining is our wheelhouse, so you just sit back while we laser cut all your 316 stainless steel parts.

Thicknesses greater than .125″ will have a factory #1 mill finish. When not deburred, the appearance will be dull with visible mill scaling.

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

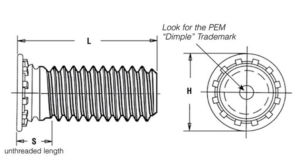

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |