Abrasion-resistant high carbon steel is one of the toughest steel alloys we offer here at SendCutSend. Spanning a range of hardnesses, impact resistances, and strengths, AR steel is a favorite of industries where abrasion and impact resistance is critical.

We offer two grades of abrasion-resistant steel: AR400 and AR500. Although similar in many ways, the two grades have several key differences that can bring individual value to many of your projects. Let’s go over the core, general properties of abrasion-resistant steel, and take a look at the specific values of both laser cut AR400 and laser cut AR500.

What Is Abrasion-Resistant Steel?

Abrasion-resistant (AR) steel is renowned for its durability and resistance to wear and tear caused by abrasion and impact. This type of steel is meticulously engineered to endure harsh conditions, making it highly suitable for applications that involve mining equipment, construction machinery, and material handling systems. One of the key properties of AR steel is its impressive hardness, which is achieved through a combination of alloying elements such as carbon, manganese, and other trace elements. This hardness allows the material to withstand the grinding and scraping actions that commonly occur during operations where abrasive materials like rocks, minerals, and sand are present. As a result, AR steel can significantly extend the lifespan of machinery and equipment subjected to abrasive environments, reducing maintenance costs and downtime.

In addition to its hardness, abrasion-resistant steel exhibits remarkable toughness and impact resistance, allowing it to absorb energy from impacts without fracturing or deforming easily. This characteristic is especially crucial in applications where impact forces are prevalent. The combination of exceptional hardness, toughness, and impact resistance makes abrasion-resistant steel an indispensable material for industries requiring robust solutions to counteract the effects of long term aggressive wear.

Advantages of AR Steel

The most common reason industries and individuals alike use AR steel is its durability, which makes AR steel ideal for long term use and continued wear resistance. Some other big advantages to using AR steel are:

- Longevity and Cost-Savings. Because AR steel boasts nearly unmatched durability, it ensures your parts and machinery last longer than their standard steel counterparts. This means less replacement and upkeep, leading to more savings over the long term.

- Structural Integrity. The combination of abrasion and impact resistance ensures the structural integrity of equipment and components. This makes AR steel valuable in heavy-duty applications where maintaining structural stability is essential.

- Abrasion Resistance. Obviously, abrasion resistance is the key advantage to using AR steel. The abrasion resistance AR steel offers extends the lifespan of your parts and allows you to use them in just about any harsh environment with little concern for their wear and tear.

How Is Abrasion-Resistant Steel Made?

The addition of carbon during the formation phase of AR steel increases its toughness and hardness, but not its core strength properties. The reason for this is due to the crystal structure that forms when the alloy is heated, cooled, and sometimes reheated before cooling slowly to its resting temperature. During the initial heating phase, the elements are heated up to 1,650°F (or 899°C). At this time, the carbon atoms “slip” into spaces between the iron atoms, preventing the iron atoms from restacking in their natural state. This is the early stage of a changing crystal structure.

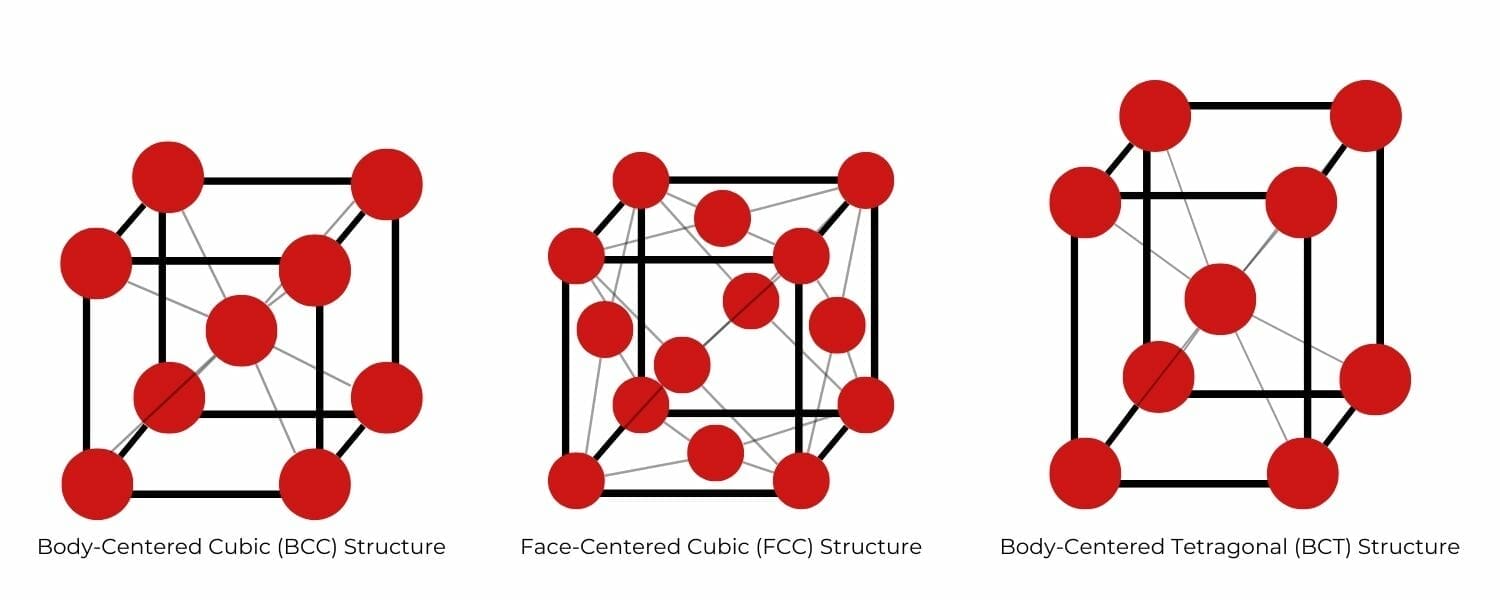

Once the material has reached the critical temperature where the atoms are in the face-centered cubic (FCC) structure, it moves to the cooling phase. At this point, the alloy is considered austenitic. This is where the process changes depending on whether or not formable AR steel is being created. If non-formable AR steel is being made, the alloy is cooled at a slow rate, allowing the carbon atoms to diffuse into the surrounding iron atoms as it attempts to restructure to a body-centered cubic (BCC) structure. We are left with cementite (Fe3C), which is exceptionally hard but very brittle, which is why it’s considered non-formable but still abrasion-resistant.

On the contrary, if formable AR steel is being made, the material is cooled rapidly through a process called “quenching,” which is done by dousing the material in water. During this rapid cooling, the carbon atoms don’t have enough time to diffuse into the surrounding iron. Instead of morphing into cementite, the carbon and iron atoms form a body-centered tetragonal (BCT) structure called Martensite, in which the carbon remains intact. The resulting alloy is softer while retaining much of the core abrasion-resistance.

The other key differences between formable and non-formable abrasion-resistant steels are the tempering process, and some small composition differences. Formable AR steel is tempered (heated slightly and slowly cooled to atmospheric temperature) to reduce some of the hardness created during the quenching phase. The composition differences between formable and non-formable versions of the same AR steel alloy are small, but not negligible, and play a significant role in the alloy’s malleability.

While creating formable abrasion-resistant steel is more costly because of the added processing necessary to soften the alloy to a workable hardness, it has a wide range of applications simply because it’s easier to work with than its non-formable counterpart. It’s important to note that although the alloy can technically be “formable,” it’s still extremely difficult to bend and manipulate without creating undue stress and cracking within the part.

We do not bend either of the AR steels we offer here at SendCutSend because regardless of its classification, it’s difficult to work the material further without compromising its core properties. Any further bending or manipulating will need to be done after you receive the parts from us.

Identifying Abrasion-Resistant Steel

Abrasion-resistant steel is abbreviated to AR, and each grade is given a Brinell Hardness Number (BHN) to indicate its hardness. The Brinell Scale measures the material’s indentation hardness and assigns it a number based on the force it took to indent the surface and the size of the indentation. The number indicated is only the nominal hardness and not always the exact hardness, so each grade has a range of average measured BHNs.

Formable abrasion-resistant steel is also denoted by an “F” after the BHN in the indicator. For example, AR600F has an average Brinell hardness of 570-625 and is formable.

Uses of Abrasion-Resistant Steel

Abrasion-resistant steel has a place in hundreds of industries and applications, but is suited to some uses better than others. Ideally, AR steel is used in applications where there is constant motion and/or abrasive material flow. This allows the parts and machinery to take full advantage of the impact and wear resistance AR steel provides.

These applications are often found in:

- Construction equipment. Construction equipment, including structural beams, bulldozers, compactors, and more, can benefit from the use of AR steel as most of this equipment will come into contact with highly abrasive media.

- Mining equipment. All of the tools used in mining and excavating need to be abrasion, wear, and impact resistant. Heavy and highly abrasive material often comes into contact with the tooling, parts, and machinery used in this industry, so AR steel isn’t just beneficial. It’s a must.

- Agricultural tooling. Most common tools and equipment you find in the agricultural industry are lined or made of abrasion-resistant steel. With constant outdoor use, this equipment directly benefits from the wear resistance AR steel provides.

AR400 Steel vs. AR500 Steel

Here at SendCutSend, we offer both AR400 and AR500 grades to suit any abrasion-resistant projects you may have. Although they share the important core properties of abrasion-resistant steel, the two metals have a few key differences which allows them to cover even more ground when it comes to their available applications.

While AR400 is known for its workability and AR500 is known for its tensile strength, each metal contains a few other hidden advantages which can directly benefit your project in any application.

AR400 Steel

Laser Cut AR400 is workable and malleable while maintaining many of the abrasion and impact resistant characteristics that make AR steel so valuable. The addition of chromium to AR400 makes it more corrosion resistant as well, making it well suited for outdoor applications where weathering is a concern.

The greatest benefit AR400 offers is its workability. Because it’s softer than most other grades of AR, it is more easily welded and manipulated without reaching the point of internal cracking or damage. Even with the added workability, AR400 is still three times harder than Mild Steel and through-hardened, so it can withstand significant impact and abuse.

Be warned, however, that while it’s one of the most workable of the AR grades, it’s still comparatively difficult to deform. Bending, rolling, and other post-processing shaping methods will take patience and significant effort.

Applications for AR400

- Heavy equipment liners

- Gun range targets

- Mining equipment

- Non-load bearing construction

- Tooling/hand tools

AR500 Steel

Laser cut AR500 steel has 1.25x the tensile strength of AR400, as well as a higher yield strength and tensile modulus. This means that AR500 is overall significantly more impact resistant than AR400, and the addition of manganese increases its sheer strength.

AR500 makes up for its lack of workability with high wear resistance, allowing it to withstand intense weathering and high impact environments. AR500 is best suited for applications where the main failure points are long-term wear and tear, as it’s through-hardened during the initial heating phase of its creation. With very little disruption to the consistency of its hardness throughout even the very center, AR500 is capable of taking hits from heavy machinery, abrasive rocks and minerals, and other destructive aggressors without weakening.

Although AR500 is one of the lowest rated steel alloys for workability, it can be welded with some practice and patience. We cannot bend, tap, or deburr AR500 in-house, and we recommend against attempting additional machining and forming such as countersinking as it can severely damage the structural integrity of the plate. If you are looking for highly workable metals, you can learn more about the differences between those materials like aluminum and steel in our article.

Applications for AR500

- Combat robotics

- Quarry equipment

- Truck plows

- Armor plating

- High caliber targets

- Cutting edges

Using Abrasion-Resistant Steel In Your Projects

Although it’s best to avoid working the material further after machining, AR steel still has a wide variety of uses. With the right application, abrasion-resistant steel can strengthen your project and protect it from most high impact environments for years to come. Its unique crystal structure, alloying elements, and through-hardening allow for some of the highest measured impact and weathering resistances in addition to its quintessential abrasion resistance.

If you’re looking to use AR steels in your next laser cut project, look no further. In thicknesses ranging from .119” (3.02mm) to .500” (12.7mm), we have all the AR400 and AR500 you could need. If AR steel isn’t the right metal for your project, we have dozens of others that will suit your needs, such as cold and hot rolled carbon steel.

Take a look at our laser cutting guidelines to ensure your parts can be machined properly, and upload your file to get instant pricing on AR steel parts today!