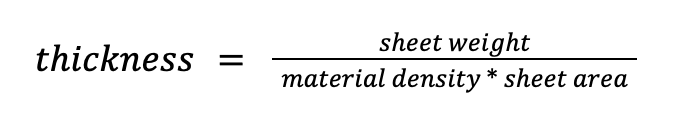

Metal gauge thickness (aka gage thickness) dates back to the 1800s, before a unit of measure for thickness was universally agreed upon. It is a way of measuring the thickness of material via density. The processes of manufacturing at the time when the gauge system was developed were crude by today’s standards, so material thickness was very inconsistent by comparison. Measuring by weight of the sheet metal was more representative of the average thickness than any one thickness measurement was likely to be (it was also easier).

Gauge Thickness for Sheet Metal vs Measured Thickness

Sheet metal gauge thickness is another way to describe the actual thickness. Think of gauge thickness vs measured thickness as being similar to the difference between metric and imperial units. Both gauge thickness and measured thickness convey a standardized measurement describing sheet metal, but just with different numbers and bases of measurement.

With metric, the base measurement is 10, i.e. 10 mm = 1 cm. For gauge thickness, the base is the number of drawing operations. This base is less consistent, as the change in thickness from 3 gauge stainless to 4 gauge is 0.016” vs from 24 to 25 gauge stainless it is only 0.003”. This is due to material properties that limited how much reduction could take place with a single drawing operation. This is also why each material has a unique gauge conversion chart due to the variations in material properties. Below is an example sheet metal gauge chart for stainless steel.

| Stainless Steel | ||

| Gauge | Decimal Equivalent [in] | Decimal Equivalent [mm] |

| 3 | 0.250 | 6.35 |

| 4 | 0.234 | 5.94 |

| 5 | 0.219 | 5.56 |

| 6 | 0.203 | 5.16 |

| 7 | 0.188 | 4.76 |

| 8 | 0.172 | 4.37 |

| 9 | 0.156 | 3.97 |

| 10 | 0.141 | 3.57 |

| 11 | 0.125 | 3.18 |

| 12 | 0.109 | 2.78 |

| 13 | 0.094 | 2.39 |

| 14 | 0.078 | 1.98 |

| 15 | 0.070 | 1.78 |

| 16 | 0.063 | 1.59 |

| 17 | 0.056 | 1.42 |

| 18 | 0.050 | 1.27 |

| 19 | 0.044 | 1.12 |

| 20 | 0.038 | 0.95 |

| 21 | 0.034 | 0.86 |

| 22 | 0.031 | 0.79 |

| 23 | 0.028 | 0.71 |

| 24 | 0.025 | 0.64 |

| 25 | 0.022 | 0.56 |

| 26 | 0.019 | 0.48 |

| 28 | 0.016 | 0.41 |

A potential challenge with gauge thickness measurement is that different materials use different gauge charts. For example, stainless steel uses a stainless steel gauge chart, while aluminum will only use an aluminum gauge chart. Since you have to use and keep track of different gauge charts, you can make the mistake of ordering the wrong thickness of material.

Here’s an example of how material thickness can vary:

- If you were to order 10 gauge stainless steel, you’re going to get a physical measurement of 0.135.”

- If you order 10 gauge aluminum, you’re going to get a physical measurement of 0.102.”

That’s a 0.033” difference, which is well outside the tolerances for most designs. Using the wrong gauge chart can be a big detriment to your design.

Types of Sheet Metal Gauge Charts

A gauge chart is a table that matches a material’s gauge to the decimal equivalent thickness. Some gauge charts will also include thickness tolerance and/or a measurement in multiple units. It is important to know the difference between gauge thickness and dimensional thickness as well as how to read a gauge chart as some industries and some metal suppliers still use the gauge system to specify sheet metal thickness (we like to make it easier on you, and directly provide an actual thickness in both inches and metric as you are ordering). Additionally, note that as the gauge number goes higher, the thickness decreases. This ties back to the origins of the gauge measurement system in the metal wire production industry, where gauge number was measured by the number of drawing operations to get to a certain sized wire. Drawing operations are simply compressing a wire while it is stretched out making it thinner. With each successive draw on the wire, the gauge number increased as wire thickness was made thinner. Due to differences in material properties, conversion from gauge number to actual thickness is unique for each material, so make sure to use the appropriate chart!

The charts below match the decimal equivalent thickness of each material to the equivalent gauge measurement in both imperial and metric units. It is important to remember that the thickness decreases as the gauge number increases. In order to use a sheet metal gauge chart, simply select the chart matching the desired material, then find the row corresponding to the desired thickness, the left column will indicate the correct gauge for that thickness.

Mild/Carbon Steel Sheet Metal Gauge Chart

| Mild Steel/Carbon Steel | ||

| Gauge | Decimal Equivalent [in] | Decimal Equivalent [mm] |

| 3 | 0.239 | 6.07 |

| 4 | 0.224 | 5.69 |

| 5 | 0.209 | 5.31 |

| 6 | 0.194 | 4.94 |

| 7 | 0.179 | 4.55 |

| 8 | 0.164 | 4.18 |

| 9 | 0.150 | 3.8 |

| 10 | 0.135 | 3.42 |

| 11 | 0.120 | 3.04 |

| 12 | 0.105 | 2.66 |

| 13 | 0.090 | 2.28 |

| 14 | 0.075 | 1.9 |

| 15 | 0.067 | 1.71 |

| 16 | 0.060 | 1.52 |

| 17 | 0.054 | 1.37 |

| 18 | 0.048 | 1.21 |

| 19 | 0.042 | 1.06 |

| 20 | 0.036 | 0.91 |

| 21 | 0.033 | 0.84 |

| 22 | 0.030 | 0.76 |

| 23 | 0.027 | 0.68 |

| 24 | 0.024 | 0.61 |

| 25 | 0.021 | 0.53 |

| 26 | 0.018 | 0.45 |

| 28 | 0.015 | 0.38 |

Galvanized Steel Sheet Metal Gauge Chart

| Galvanized Steel | ||

| Gauge | Decimal Equivalent [in] | Decimal Equivalent [mm] |

| 8 | 0.168 | 4.27 |

| 9 | 0.153 | 3.89 |

| 10 | 0.138 | 3.51 |

| 11 | 0.123 | 3.13 |

| 12 | 0.108 | 2.75 |

| 13 | 0.093 | 2.37 |

| 14 | 0.079 | 1.99 |

| 15 | 0.071 | 1.8 |

| 16 | 0.064 | 1.61 |

| 17 | 0.058 | 1.46 |

| 18 | 0.052 | 1.31 |

| 19 | 0.046 | 1.16 |

| 20 | 0.040 | 1.01 |

| 21 | 0.034 | 0.93 |

| 22 | 0.034 | 0.85 |

| 23 | 0.031 | 0.78 |

| 24 | 0.028 | 0.7 |

| 25 | 0.025 | 0.63 |

| 26 | 0.022 | 0.55 |

| 28 | 0.019 | 0.47 |

Stainless Steel Sheet Metal Gauge Chart

| Stainless Steel | ||

| Gauge | Decimal Equivalent [in] | Decimal Equivalent [mm] |

| 3 | 0.250 | 6.35 |

| 4 | 0.234 | 5.94 |

| 5 | 0.219 | 5.56 |

| 6 | 0.203 | 5.16 |

| 7 | 0.188 | 4.76 |

| 8 | 0.172 | 4.37 |

| 9 | 0.156 | 3.97 |

| 10 | 0.141 | 3.57 |

| 11 | 0.125 | 3.18 |

| 12 | 0.109 | 2.78 |

| 13 | 0.094 | 2.39 |

| 14 | 0.078 | 1.98 |

| 15 | 0.070 | 1.78 |

| 16 | 0.063 | 1.59 |

| 17 | 0.056 | 1.42 |

| 18 | 0.050 | 1.27 |

| 19 | 0.044 | 1.12 |

| 20 | 0.038 | 0.95 |

| 21 | 0.034 | 0.86 |

| 22 | 0.031 | 0.79 |

| 23 | 0.028 | 0.71 |

| 24 | 0.025 | 0.64 |

| 25 | 0.022 | 0.56 |

| 26 | 0.019 | 0.48 |

| 28 | 0.016 | 0.41 |

Aluminum Sheet Metal Gauge Chart

| Aluminum | ||

| Gauge | Decimal Equivalent [in] | Decimal Equivalent [mm] |

| 3 | 0.229 | 5.83 |

| 4 | 0.204 | 5.19 |

| 5 | 0.182 | 4.62 |

| 6 | 0.162 | 4.11 |

| 7 | 0.144 | 3.67 |

| 8 | 0.129 | 3.26 |

| 9 | 0.114 | 2.91 |

| 10 | 0.102 | 2.59 |

| 11 | 0.091 | 2.30 |

| 12 | 0.081 | 2.05 |

| 13 | 0.072 | 1.83 |

| 14 | 0.064 | 1.63 |

| 15 | 0.057 | 1.45 |

| 16 | 0.051 | 1.29 |

| 17 | 0.045 | 1.14 |

| 18 | 0.040 | 1.02 |

| 19 | 0.036 | 0.91 |

| 20 | 0.032 | 0.81 |

| 21 | 0.028 | 0.71 |

| 22 | 0.025 | 0.64 |

| 23 | 0.023 | 0.58 |

| 24 | 0.020 | 0.51 |

| 25 | 0.018 | 0.46 |

| 26 | 0.017 | 0.43 |

| 28 | 0.013 | 0.32 |

Sheet Metal Gauge: 4 Tips to Make the Right Selection for Your Project

Below are outlined four things to keep in mind when selecting materials and/or gauge thickness for your next project. For more in depth material selection guidance, check out our article on it here: Material Selection Guide.

Consider material properties

What is driving your material selection, and what material best meets your design requirements? For example, a stronger material might allow for a thinner gauge of metal.

- Consider:

- Material strength

- Density

- Corrosion resistance

- Cost

- Malleability

- Conductivity

- etc.

Choose a process

What process is being done on the metal can change material selections

- Bending – Consider reading our guide: Design Considerations When Planning Sheet Metal Bends

- Some metals are more malleable and thus bend better

- Some metals have a max or minimum material thickness for bends

- Welding

- Some metals weld better than others (i.e. mild steel is easier to weld than stainless steel)

- Some metals have a max or minimum material thickness for welds

- Is your material reliant on heat treatment for proper performance?

- Welding removes heat treatments in the welded region

Define the necessary thickness

- Take into account the thickness required for a part

- Does it need to support a certain weight?

- Can it flex or does it need to be very stiff?

- Does it have a maximum weight?

Reduce production and shipping costs

- Thicker materials drive up cost of both production and shipping

- Choose the thinnest material that meets the required thickness to minimize cost

Video Guide to Understanding Sheet Metal Gauge Thickness

Watch the video and follow along with the transcript below to learn the difference between gauge thickness and actual thickness, and how SendCutSend is making it easier for you to pick what’s best for your project.

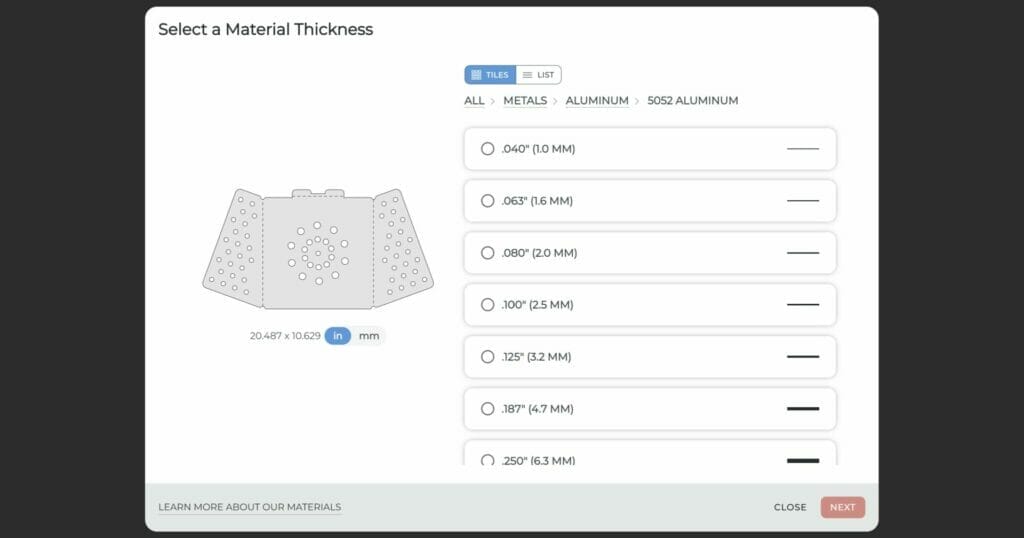

Material Selection: How SendCutSend Helps with Sheet Metal Selection

Utilizing the proper material thickness is very important to make sure parts work safely, are efficient with weight, and to keep costs down. To protect your design and help prevent you from ordering the wrong material thickness, we made it easy with our material selection guide. You’re going to see all the physical measurements that we have for that material in both imperial (inches) and metric (millimeters) units. Choosing your thickness based on what’s physically measured off the material will help prevent any costly mistakes you could make when ordering parts based only off of gauge thickness.

If you have any questions, feel free to reach out to our support team. When you’re ready, upload your design and get instant pricing today!

If you are new to SendCutSend, here’s a handy step-by-step guide on how to order parts from us: How to Order Parts from SendCutSend (spoiler alert: it’s super simple and intuitive to order from us).

Sheet Metal Gauge FAQs

18 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so reducing the wire size 20 times results in a smaller diameter than 18 times.

Sheet metal gauge refers to the thickness of sheet metal. It is unique to the type of metal, i.e. 10 gauge stainless steel is not the same thickness as 10 gauge aluminum.

14 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so reducing the wire size 16 times results in a smaller diameter than 14 times.

Metals beyond ¼ inch thickness are considered plate metal instead of sheet metal and are measured with a decimal or fractional thickness.

12 gauge mild steel is 0.105” [2.66 mm] thick.