Prototyping is a useful tool in everything from product development to aftermarket automotive parts. In fact, if you’re reading this, there’s probably a good chance you have quite a bit of experience with prototyping. If this is the case, you’ve probably also asked yourself, “Is this worth the time, effort, and money I’m putting into it?” Prototyping can require special equipment, added time, and more materials than you originally bargained for at the beginning of your project. That being said, it’s an integral part of the engineering and design process and shouldn’t be skipped.

There are dozens of kinds of machining available that works for prototyping and finding one that cuts down on your spent time and money is no easy task. We’re here to help you find what works best for prototyping and give some solutions to this well-known problem. Keep reading to learn how online laser cutting can help your prototyping.

Selecting the Right Prototyping Process

Rapid prototyping happens at the beginning of the design process and normally involves problem solving when it comes to fit and function of the final product. At this early stage, using the exact same material that’s going to be used in the final product is usually not necessary. For this reason, most engineers will choose to prototype using a cheaper substitute material and a more accessible, simple machining process. This way if they need to do several iterations on their prototype, they have put less time and money into the problem solving process, leaving more room in the budget for the development and quality of the final product.

Prototyping processes cover a large range of machining styles depending on the scale of the project and its needs. One of the most popular machining processes for rapid prototyping is 3D printing. 3D printing is accessible, relatively inexpensive, and can be scaled up virtually infinitely to fit the size of the project. Another popular machining process is CNC machining. CNC machining covers CNC routers, laser cutters, waterjet cutters, and several other computer operated machining processes. Many small shops are outfitted with small router tables or low-power laser cutters but having access to higher power machinery is a game-changer for prototyping.

The following table will break down four of the key factors to take into account when choosing a machining process for prototyping: speed, materials used, cost, and level of convenience.

| Process | Speed | Materials | Cost | Convenience |

|---|---|---|---|---|

| 3D Printing | 3D printing speed depends on the infill and the size of the part, but most printers print at an average of 50mm per second. Small parts can take 5-10 minutes while larger, more complicated parts can take a couple of days. | The most common and affordable material used in 3D printing is PLA. Its low melting point makes it extremely easy to print even for beginners. | 3D printers have a huge price range, but most small shops and hobbyists will purchase multiple small, cheaper printers rather than one big, high end one. The most commonly used is an Ender, which retails for $170 per printer. A spool of PLA filament costs around $25. | 3D printing is one of the most convenient methods because a small 3D printer is inexpensive and only slightly larger than a kitchen counter appliance. It fits well in a home workshop or in a fleet of 12 3D printers running simultaneously. |

| Laser Cutting | For thin materials, laser cutting is one of the fastest machining methods available. Parts can be cut in seconds, even with a 120w laser which most small shops employ. | Small, lower power lasers can cut plywood, acrylic, and polycarbonate. A 120w laser cannot cut metal, unlike the 12kw fiber lasers we use here at SendCutSend. | Purchasing a small laser cutter is no low-budget task. A 120w, 51” bed laser cutter can cost around $15,000, with material costs adding onto that. The continued maintenance is also a significant added cost. | Having a laser cutter right out in your garage is extremely convenient, but providing the space, ventilation, and electrical access to it is difficult. Utilizing online laser cutting services is cheaper and more convenient! |

| Router | A small CNC router is a little slower than even a low-power laser cutter, but a table of parts can still be cut in a few minutes. | Small table-top routers are capable of cutting wood, plastics, and some metals in thinner sheets. | A medium sized bed router will set you back up to $15,000 depending on the power, speed, and material cutting capability you need. A table-top router capable of cutting metal can cost around $1,500. | With smaller options available, owning and operating a CNC router can be a little more convenient than owning a laser cutter, though you lose some power and material options doing this over ordering parts from a larger CNC router machining shop. |

| Waterjet Cutting | Waterjet cutting is the slower of the three 2D manufacturing options we’ve mentioned here, but even large parts can be cut in a handful of minutes thanks to the high-powered jet stream. | Waterjet cutting is one of the best options for cutting composites like carbon fiber and G-10 because it cuts down on the dust that is produced during machining, keeping operators safe and the workspace cleaner. | A waterjet cutter is not really a feasible cost for most small shops and hobbyists between the cost of the unit itself (~$20,000) and the cost of media, maintenance, and cleaning. | Since most people have to order waterjet cut parts from large machine shops, it’s a little less convenient than having a 3D printer in your closet. But our waterjet cut parts are cut soon after you place your order and shipped within 2-4 business days. |

CNC Machining vs. 3D Printing: What Works Best for Prototype Manufacturing?

Choosing between machining methods for the best prototyping results is entirely dependent on the needs and scope of your project. And in some cases, you may want to use a mix of multiple methods and media to achieve the desired result.

As we laid out in the table above, when it comes down to doing all your prototyping in-house, 3D printing is convenient, accessible, and inexpensive. There are a couple major downsides to 3D printing, however. There’s a big learning curve to tuning and successfully printing part after part, so it takes some invested time before you’re ready to use 3D printing for all your prototyping. The other hurdle to using only 3D printing for prototyping is the size limitation. The standard bed size for a general use 3D printer is 6”-12”, which puts a relatively small size cap on each individual part being prototyped.

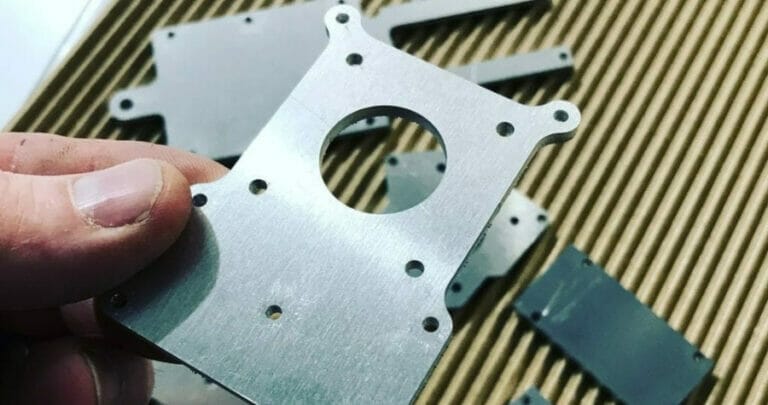

These downsides to 3D printing can be mitigated by using CNC machined parts alongside your 3D printed parts. Even small CNC machinery has larger bed sizes than most 3D printers, making it possible to create full size prototypes of bigger parts without needing to fasten multiple pieces together. Mixing 3D printed plastic with material that’s closer to the real product like plywood or aluminum also allows you to work with something that’s a similar weight, feel, or look to the end design.

We can’t decide for you which process is better for your projects, but using a variety of machining resources and materials will let you get the best of both worlds while maintaining a low time and money sunk cost.

DIY vs. Outsourcing: Should You Invest in Equipment for Prototyping at Home?

The easiest way to get around the time, convenience, and machinery ownership expenses is to outsource your prototyping production. Learning to CAD and getting a small 3D printer can be a huge help for early prototyping, but beyond that point, outsourcing to SendCutSend allows you to have the convenience of having a machine shop in your garage with none of the expenses and upkeep.

One of the great things about using SendCutSend for prototyping production is that you aren’t limited on the type of material to use for your prototypes. Depending on where you’re at in the prototyping process, you can do a small run of parts in the final material or you can choose one of our affordable substitutes like chipboard or MDF. Our CO2 laser cut chipboard is perfect for prototyping because it can be fastened using a variety of methods, bent by hand, and is one of the most affordable materials we offer.

Since time is also a concern with prototyping, we work hard to make sure your parts are shipped as quickly as possible once you have uploaded your file for laser cutting. Standard orders are shipped within 2-4 days of placing your order, and shipping only takes 3-5 days. Outside of the production and shipping time, one of the great hurdles to outsourced CNC machining is trying to get a quote. With so many places, you have to fill out a form, wait for a call or email, and spend several days hammering out the details only to learn that their pricing is way out of budget and impractical for small prototyping runs. Here at SendCutSend, all you have to do is upload your file to our website, make your material selections, and you’ll see an instant accurate quote with no wait times and no fuss. Quantity discounts start at just two identical parts, and there are no order minimums. It’s easier than pressing “start” on a 3D printer!

One of our longtime customers has prototyping with SendCutSend down to a science: he gets his instant pricing, places the order, and then starts on the next round of prototyping or a new project altogether while waiting on his order to arrive. He doesn’t have to wait for long, though!

“I can’t imagine being able to produce these parts in volume at the price SendCutSend can. For me it’s not just the price, it’s the headache of owning, maintaining, and running my own equipment. Even making prototype parts made sense since they do low volume at great prices. I have used a couple other online services that weren’t quite as smooth, but this online on-demand production model seems to make a lot of sense, especially when the part is pretty simple. And with the super fast shipping, I just work on other parts of my project while I wait. The entire ordering process was so painless I thought it was too good to be true at first.” -Phil, SendCutSend customer

Phil isn’t the only customer who can attest to the convenience of prototyping with SendCutSend. You can read about how Foothill Products uses laser cutting to make their products even better in this article.

Prototyping with SendCutSend’s Lightning Speed, Top-notch Services

Relying on SendCutSend for prototype manufacturing gives you back all the time you need to perfect your product and keep your business running smoothly. Our high-quality, affordable materials keep you well within budget without having to compromise the overall quality of your process or the end product.

Best of all, our amazing support team is available seven days a week to help you find the best solutions for your project! If you have questions, just reach out to our support team anytime.

If your parts fit within our guidelines and you’re ready to place an order, you can upload your file now and get an instant quote!