Mild steel is a versatile, low-carbon steel perfect for parts that need to be cut, welded, and formed easily. At SendCutSend, we offer three main types: 1008, A36, and A1018, each with slightly different properties suited for various applications. Whether you’re looking for a clean finish, structural strength, or cost-effective fabrication, mild steel might be just the fit for your next project.

In this article:

- What “mild steel” means and why it’s one of the most versatile steels for manufacturing

- Differences between 1008, A36, and A1018 mild steel, including uses, properties, and finishes

- How carbon content impacts workability and why low-carbon steels are great for fabrication

- Cost and aesthetic considerations for choosing the right type of mild steel for your project

The History of Mild Steel

More than 150 years the steel industry coined the term “mild” for steel with low carbon content—typically around 0.05% to 0.25%. The rest is iron with trace elements like manganese, sulfur, and phosphorus to boost machinability, minimize brittleness, and add strength. Lower carbon content also means it’s easier to cut, weld, bend, and form, making it the workhorse of steel types for manufacturing. In contrast, higher-carbon steels like 4140 alloy or certain tool steels may offer better durability or corrosion resistance but can be much pricier.

SendCutSend’s Mild Steel Offerings: 1008, A36, and A1018

Let’s focus on the mild steels we offer at SendCutSend: 1008, A36, and A1018. They’re similar in composition and function but have a few key differences.

Cold Rolled 1008: Known for its weldability, good mechanical strength, and excellent formability, 1008 has around 0.08% carbon. It’s a favorite for everything from automotive panels and fuel tanks to brackets, fasteners, hinges, and handles.

HRP&O A36: Common in construction, this low-carbon steel is likely all around you if you’re in a commercial building or near a bridge, showing up as I-beams, channels, and plate. It’s hot rolled, which gives it a bit more of an “industrial” look than cold-rolled 1008. A36 has a slightly higher carbon content, but functionally, it’s nearly identical.

HRP&O A1018: Also hot rolled, A1018 is pickled and oiled after rolling, making it cleaner and more polished in appearance. Known as HRPO (Hot Rolled Pickled and Oiled), A1018 lands between 1008 and A36 with a carbon content of 0.18%. It’s slightly less strong but has higher ductility than A36.

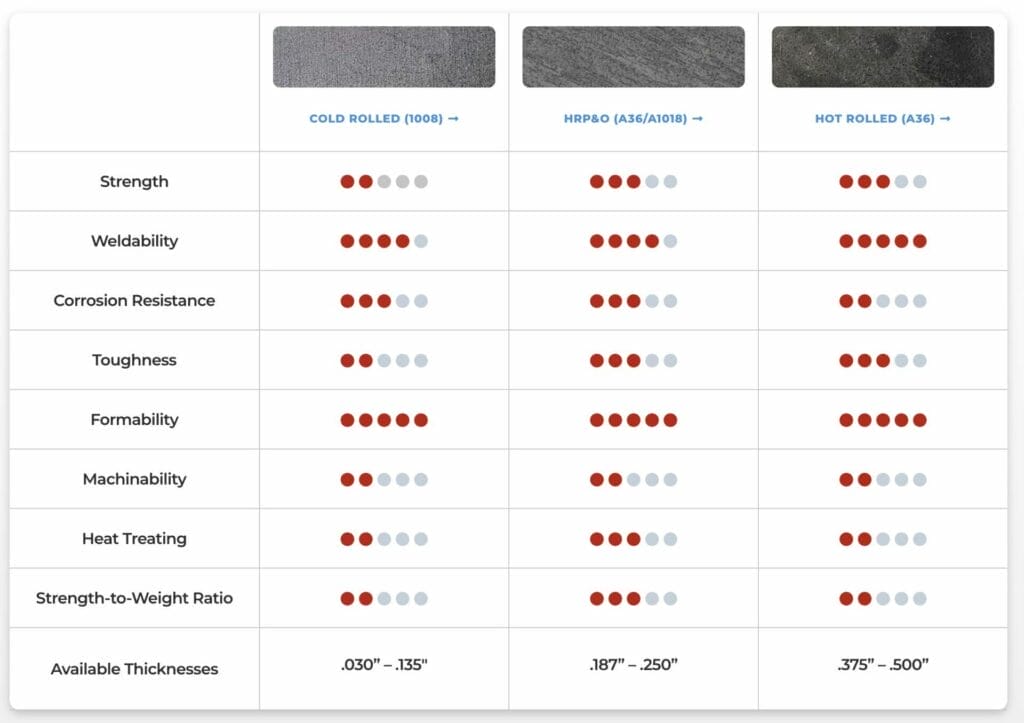

Here is a handy chart comparing our three mild steel offerings

Hot vs. Cold Rolled vs. HRPO

Wondering what the differences are? Without diving too deep into the steelmaking process, here’s a quick overview: 1008 is commonly available in thinner gauges, while A1018 and A36 are more often sold as plates. A36 has some scale and surface roughness, which is no big deal for parts that won’t be visible, but for cosmetic purposes, you’ll want to go with A1018 HRPO or 1008.

Price is also something to consider. For example, a laser-cut 8” trigger wheel made from 0.375” A36 costs a little over fifty bucks at SendCutSend. The same wheel in 0.250” HRPO costs $39.94, while a 0.135” version in 1008 comes in at $31.22. For bulk orders, the differences can add up, but for small runs, pick the thickness that works best for you. Here are some additional examples of how much specific parts and materials cost with SendCutSend.

More Than Just Mild Steel

Not feeling mild steel? No worries! SendCutSend offers a range of other materials, including AR400 and AR500 for abrasion resistance, spring steel for stiffness, and even 4130 Chromoly, a top choice in aerospace and motorsports. You’ll also find options in aluminum, copper, brass, stainless steel, wood, plastics, and composites.

Ready to bring your project to life? Upload your design, choose your material, and let’s get cutting. If you have any questions, reach out at support@sendcutsend.com