SendCutSend’s sheet metal deburring service will remove any major manufacturing imperfections such as dross, burr, or handling scratches. While they won’t have a perfect surface finish, the parts will be prepped for further finishing processes and assembly.

Watch the video and follow along with the transcript below to walk through SendCutSend’s deburring process.

Video Guide to Sheet Metal Deburring

What to expect from freshly laser cut parts

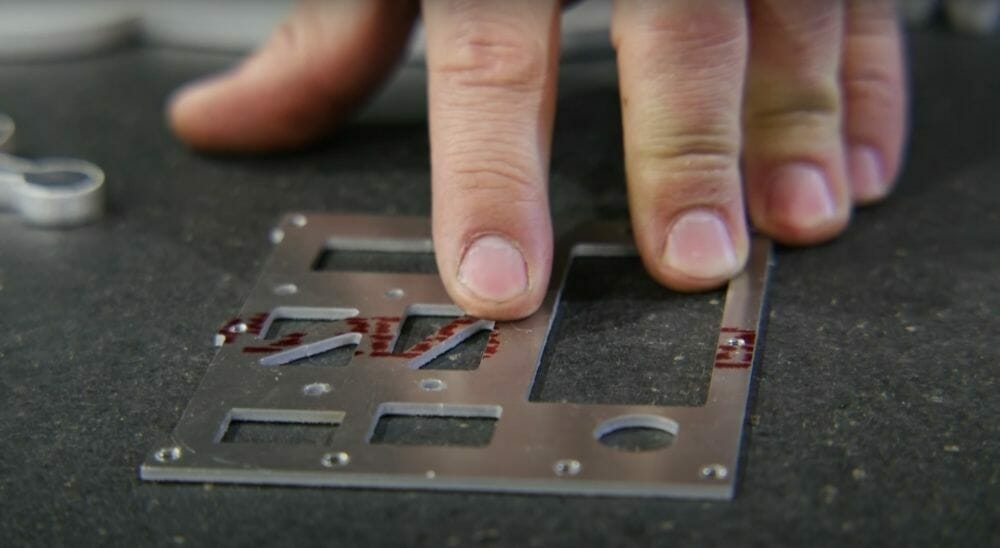

Once your parts come out of the laser, they might have some scale and porosity, minor handling scratches, and markings from the raw material.

The parts may also have a little bit of a burr on the edge from the manufacturing process. (Click through the images on your chosen material page to see how dross and burr can affect your part.)

Removing imperfections with linear deburring

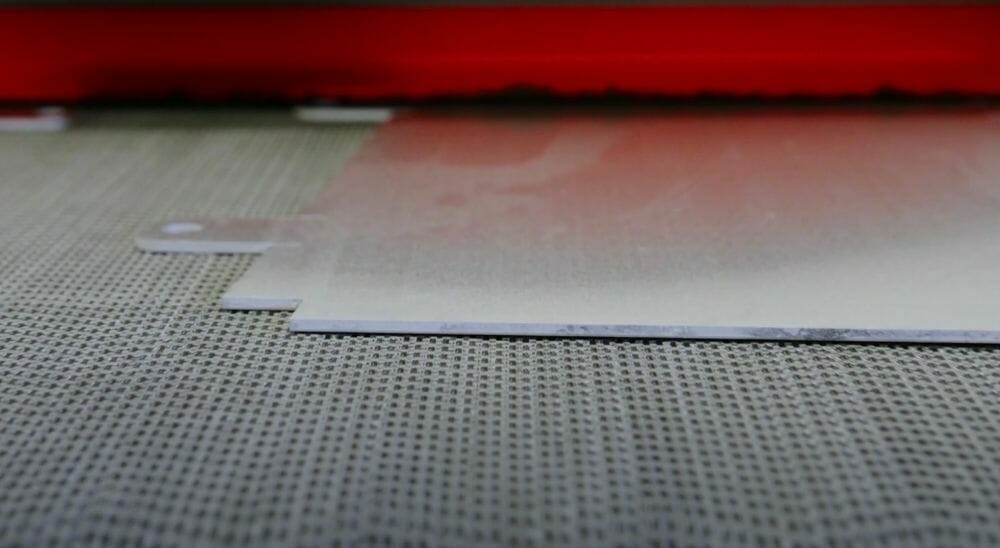

We remove the majority of the machining imperfections using a linear deburring machine. This is also a belt sander, commonly referred to as a ‘Time Saver.’

The linear deburring process is best suited for flat sheet metal parts, but they have to fit within our deburring minimum and maximum part sizes.

What to expect from linear deburred metal parts

Here at SendCutSend, we use the minimum amount of pressure in the deburring machine to remove that burred edge on your parts.

When you receive your parts, you can expect:

- The part should be free of a burr on the outside surface of both sides.

- There may still be a somewhat sharp edge as this process doesn’t roll the edge, and just removes the burr on the outside face.

- Your part might have some imperfections and small handling scratches as it goes through the rest of processing,

- There shouldn’t be any raw material manufacturing markings left on the part.

How to order deburred parts from SendCutSend

Parts that meet our criteria are pre-selected to go through this deburring process during checkout. If you don’t want your parts to go through this process, make sure you uncheck the box that says “deburring.”

If you have any other questions regarding linear deburring, check out our deburring FAQs.

Don’t hesitate to reach out to us anytime!