We machine and process your parts as quickly as possible, but keep in mind that anodizing will add 7-10 business days to the processing time for your order.

For the best turnaround times, we recommend splitting any parts that require anodizing into their own separate order This allows us to process the anodized parts separately and ship your non-anodized parts as soon as they’re ready.

Many non-ferrous metals can be anodized, but aluminum is the best candidate and creates the most successful finish. At this time, we offer three different aluminum alloys for sulfuric anodizing:

Colors may vary by batch. Click swatches to view.

All anodized parts must be at least 1″ x 3″ when flat to meet handling and deburring needs. The shortest dimension should be no smaller than 1″, and the whole square area of the part should be no less than 3”.

Anodized parts can be a maximum of 23” x 23” when flat (prior to any required bending services). Anodizing limits the maximum size of the part, but keep in mind that your parts also need to fit within linear deburring geometry requirements. Deburring will be a preselected option on all anodized parts.

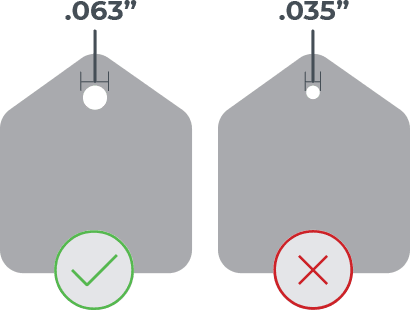

We require that all anodized parts include a hole for processing. The hole must be a minimum of .063” (1.60mm), but if your chosen material and thickness has a minimum hole size that’s larger than .063” (1.60mm), the provided hole should align with that hole size instead.

Minimum hole size is approximately 50% of the material thickness for laser cut materials. Confirm the minimum hole size for each material thickness by referencing the specifications listed in our Material Catalog.