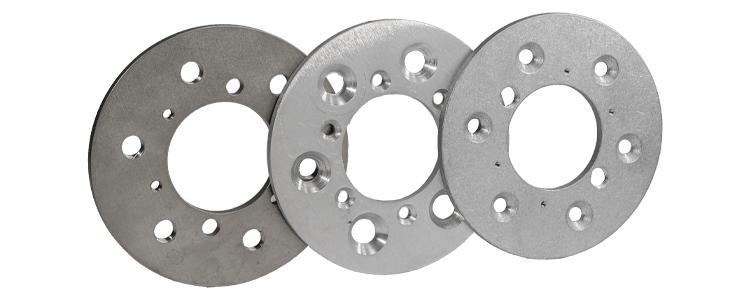

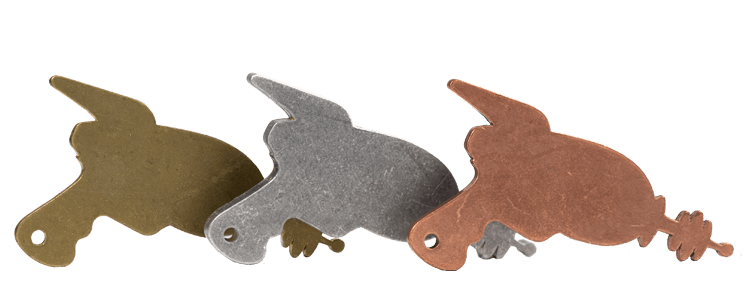

Size: 3.5 x 21.5″

Laser Cutting, Dimple Forming, Deburring

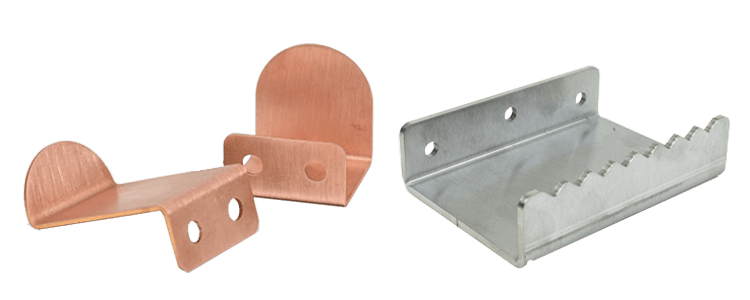

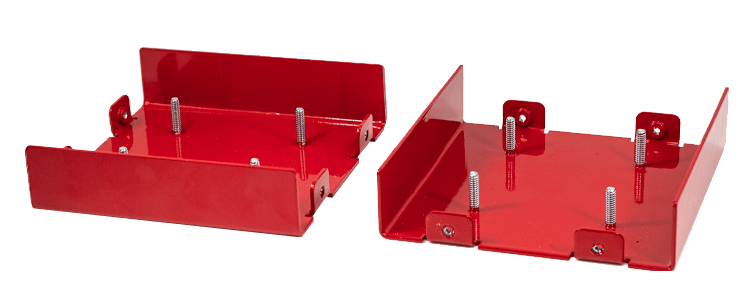

Size: 18.12 x 12.5″

Laser Cutting, Bending, Dimple Forming, Powder Coating

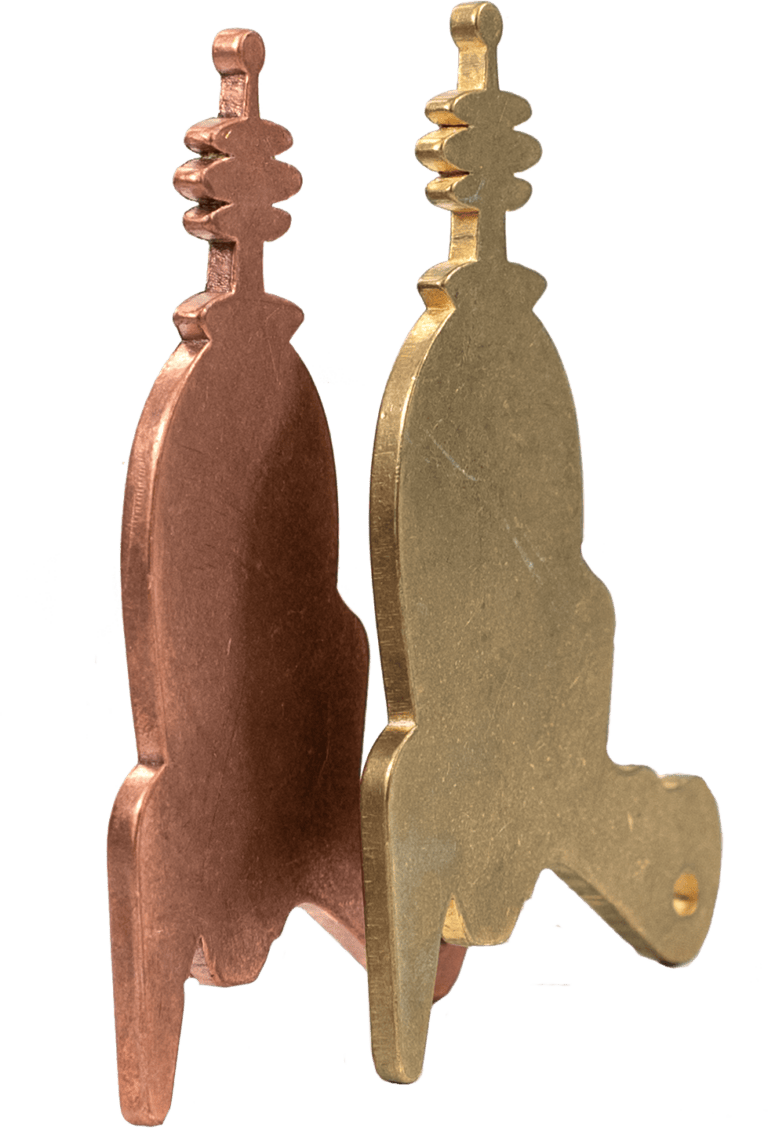

Size: 25.76 x 10.8″

Laser Cutting, Bending, Dimple Forming, Deburring

We accept .ai, .eps, .dwg, .dxf, step, and .stp

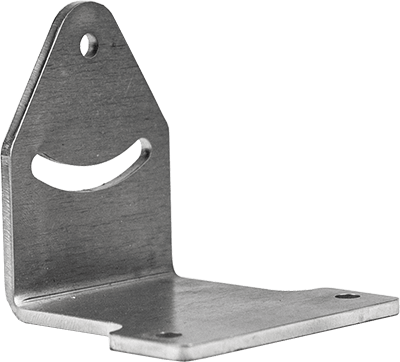

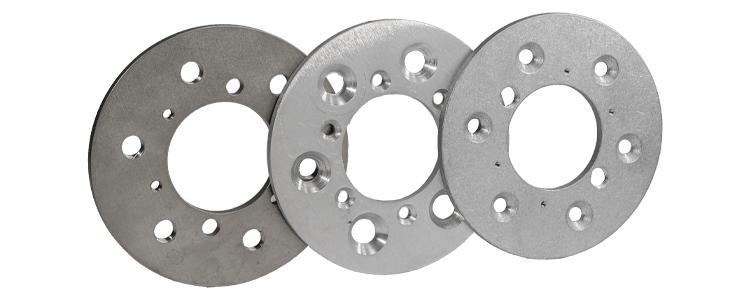

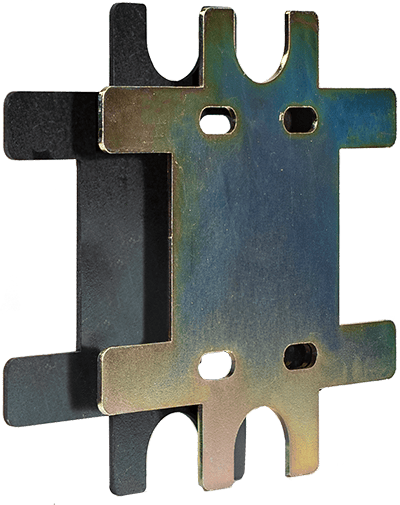

5.6 x 5.6″

Laser Cutting, Dimple Forming

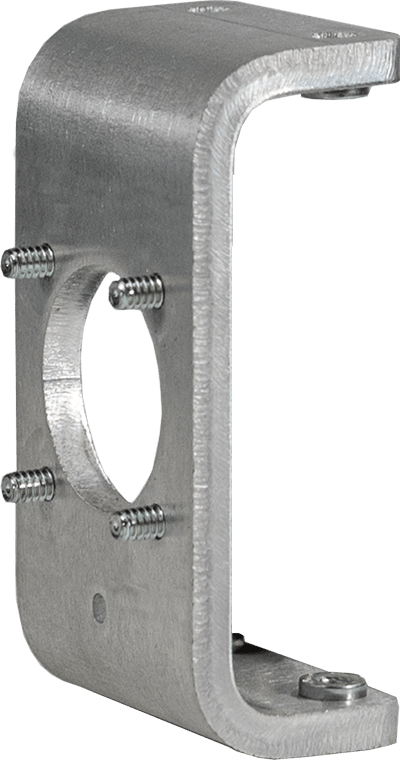

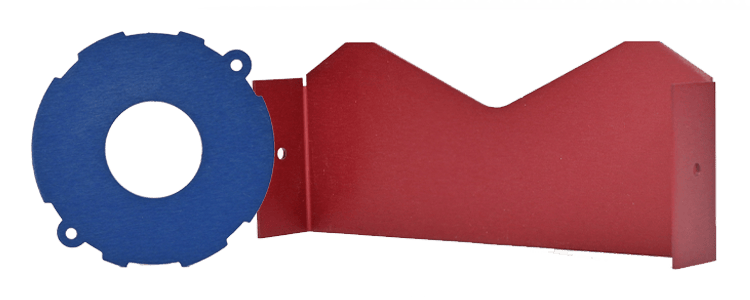

18.12 x 12.5″

Laser Cutting, Bending, Dimple Forming, Powder Coating

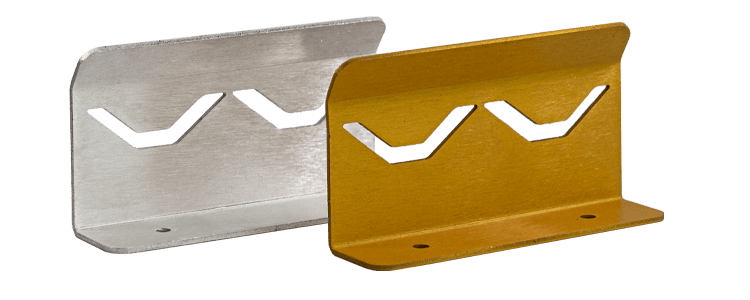

25.76 x 10.8″

Laser Cutting, Bending, Dimple Forming, Deburring

“Great experience working with SCS. Super easy to use website with great documentation and resources for reference. Turnaround time was also extremely fast. Order and received my parts within a week! Also love the vacuum formed packaging – great way to securely ship a wide variety of parts in different shapes and sizes. Will definitely be a returning customer for both professional and personal projects.”

When you need increased strength and rigidity for your parts in a lightweight material, dimple forming is the solution. We’ve made it simple to add dimples to your parts. When you upload your design to our app, simply select the “Dimple Forming” option during the checkout process and you’ll get an instant quote!

Mak sure your file meets our requirements to ensure you get your parts as quickly as possible.

Mak sure your file meets our requirements to ensure you get your parts as quickly as possible.

Choose your material, add dimples, and adjust quantity to see live pricing and shipping updates.

We accept, .ai, .dwg, .dxf, .step. or .stp files. We have our Parts Builder or Design Services available if you don’t have a file handy.

Standard production on dimple formed parts is 3-7 days with 1-3 day shipping.

We accept, .ai, .dwg, .dxf, .step. or .stp files. We have our Parts Builder or Design Services available if you don’t have a file handy.

Choose your material, add dimples, and adjust quantity to see live pricing and shipping updates.

Standard production on dimple formed parts is 3-7 days with 1-3 day shipping.

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

Before you upload your design, take a look at our file preparation guidelines. They cover everything you need to know including file setup, sizing, supported formats, and tips for keeping costs down, so you can get the best results from your dimpled parts.

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 13 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 4 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+3-5 days | 10 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

Top Quality Store

Please note: Pricing examples on our website are provided as general estimates and may not always reflect current prices. While we strive to keep these examples accurate, uploading your file is the best way to see instant current pricing.

Yes, it’s important to maintain proper spacing between dimples and from edges to prevent material distortion. Before uploading your design, check out our dimple forming guidelines to make sure your file meets SendCutSend’s requirements.

Absolutely. Dimple forming can be integrated with laser cutting, bending, tapping, and finishing services.

By creating a flared geometry around a hole, dimple forming distributes stress more evenly across the sheet metal. This reduces the likelihood of deformation under load and increases the overall stiffness of the part, making it more durable in demanding applications.