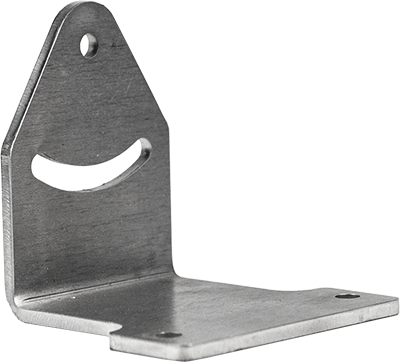

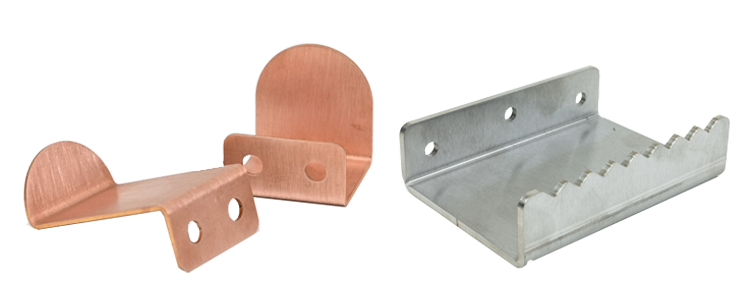

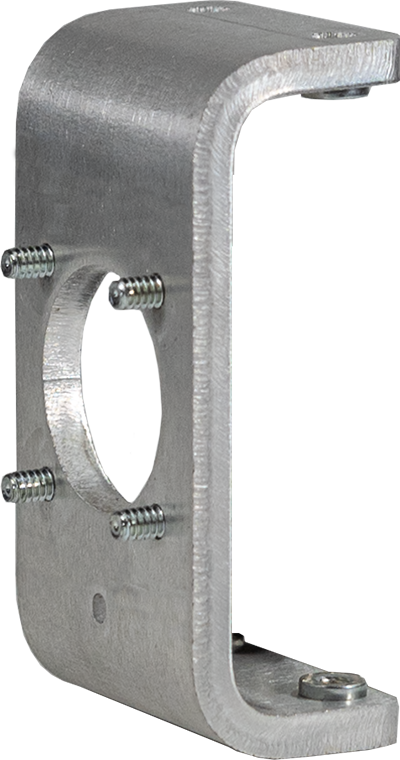

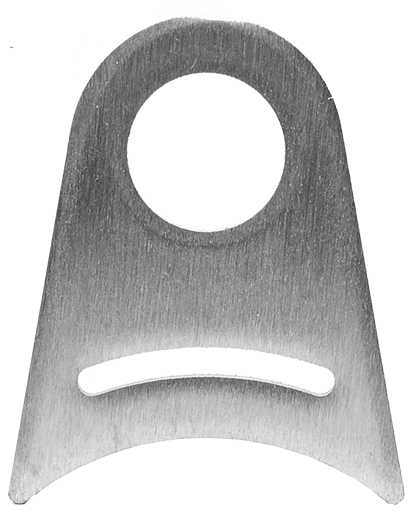

Size: 3 x 1.5″

Laser Cutting, Hardware

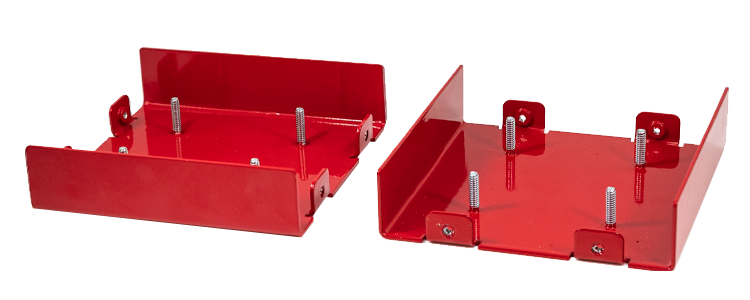

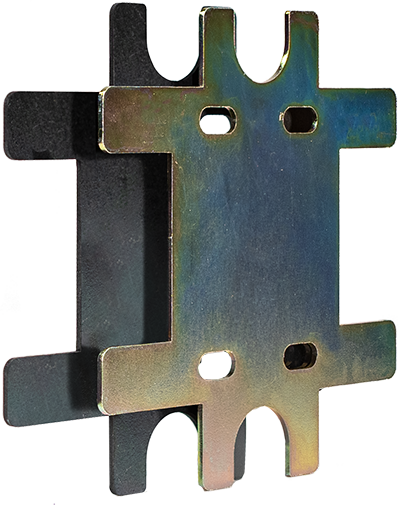

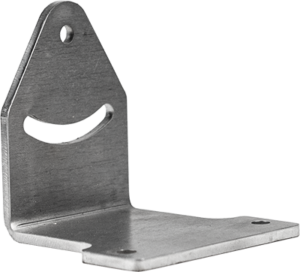

Size: 3 x 3″

Laser Cutting, Bending, Hardware

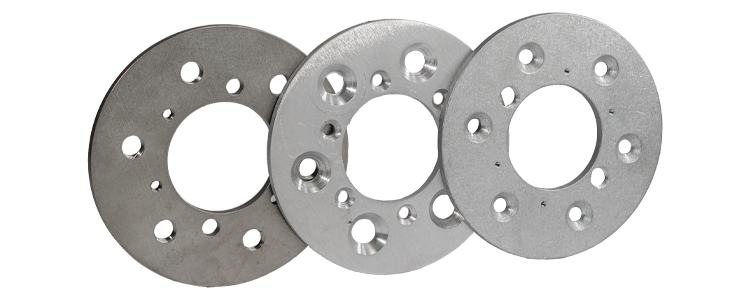

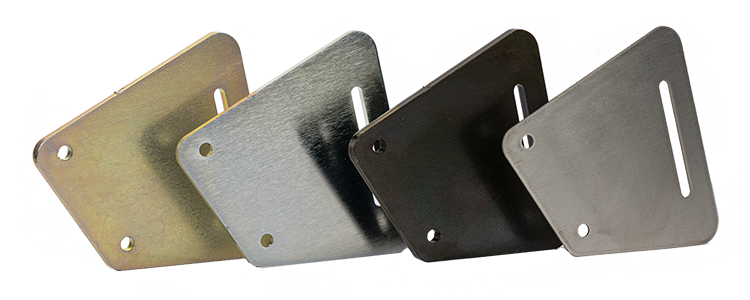

Size: 3 x 6″

CNC Routing, Bending, Plating

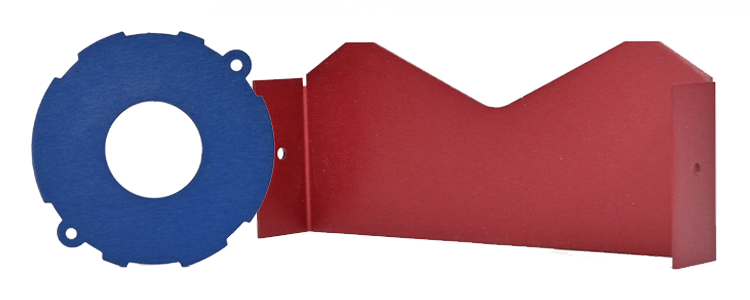

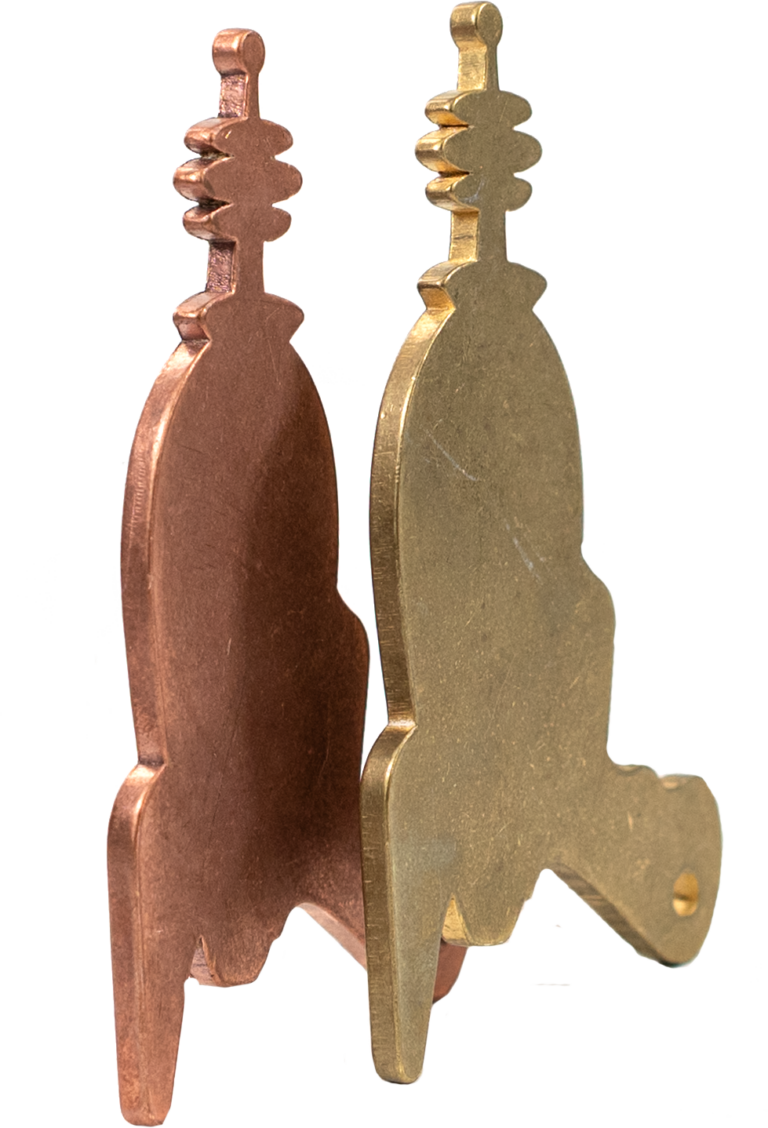

Size: 5.4 x 6″

Laser Cutting, Bending, Hardware, Anodizing

We accept .ai, .eps, .dwg, .dxf, step, and .stp

3 x 3″

Laser Cutting, Hardware, Bending

4.1 x 1.5″

Laser Cutting, Bending, Hardware, Deburring

5.4 x 6″

Laser Cutting, Bending, Hardware

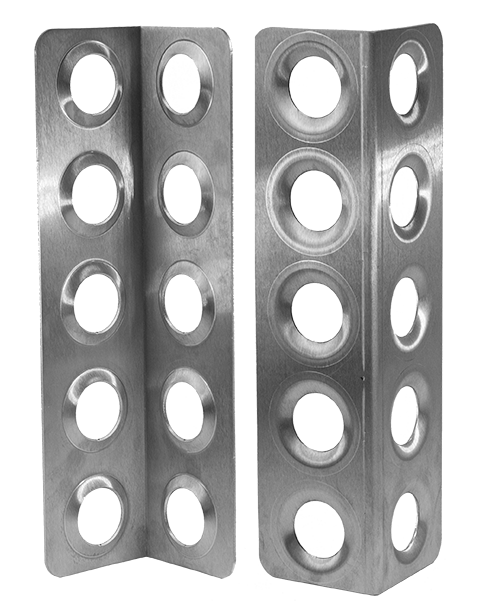

Hardware provides options when there is little to no access to the backside of a part after installation or in place of tapping in thin or soft materials. We are proud to offer a variety of PEM(R) fasteners.

Self-clinching studs are designed to be a permanent fastener in your assembly made to withstand high torque, stress and weight in a variety of applications

Press fit nuts are internally threaded with a knurled outer diameter providing a lightweight, simple option for parts that are too thin to be tapped. Choose from standard or flush.

Press fit standoffs provide a secure, threaded fasting with uniform spacing between parts.

“I’ve now used [SendCutSend] several more times and each and every order is flawless. I used their insertion products to add flush mount studs to some parts and they were all installed perfectly and they’ve held up to some serious repeated abuse.”

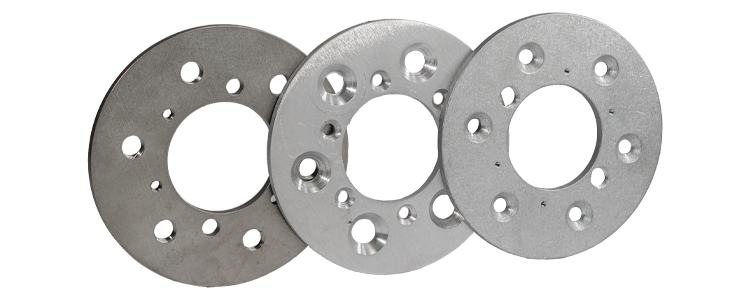

Fasteners are fully supported across seven metal types and thickness ranges.

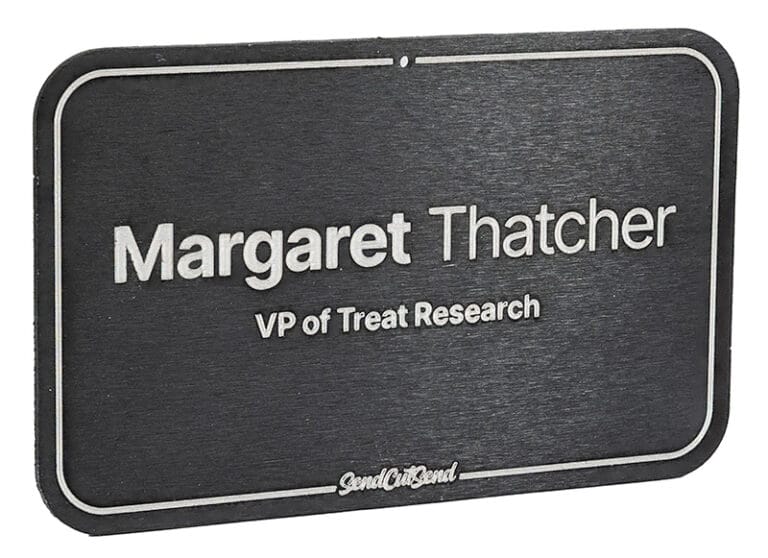

SendCutSend offers a variety of sheet metal post processing services for laser, waterjet and CNC machined parts including hardware insertion providing speed, precision and convenience.

Make sure your file meets our requirements to ensure you get your parts as quickly as possible.

Make sure your file meets our requirements to ensure you get your parts as quickly as possible.

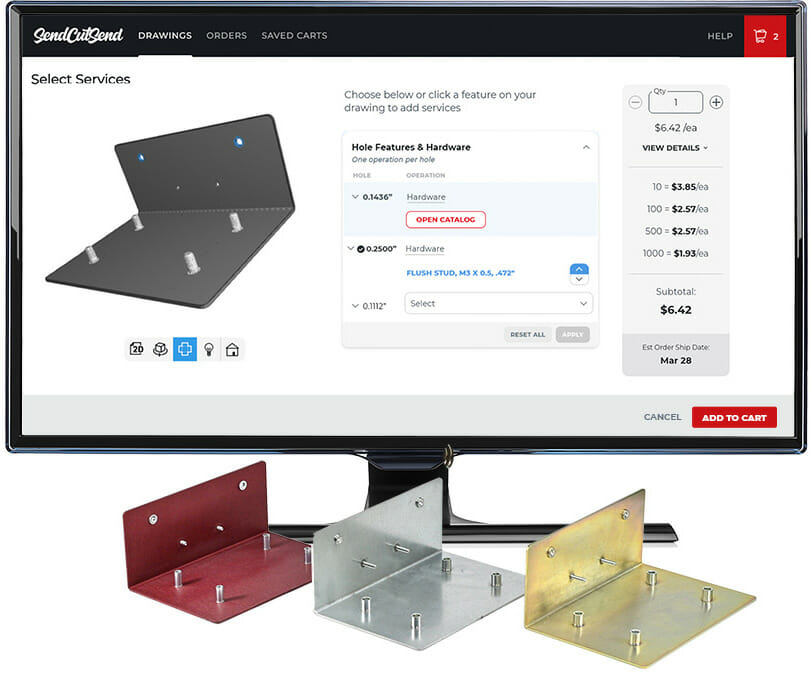

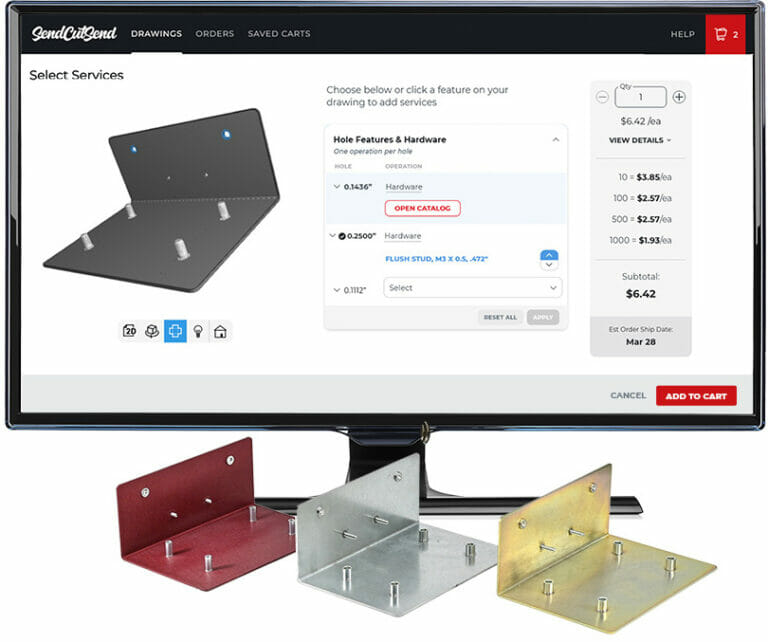

Choose your material, add your hardware, and adjust your quantity to see live pricing updates.

We accept, .ai, .dwg, .dxf, .step. or .stp files. We have our Parts Builder available if you don’t have a file handy.

Standard production on hardware installation is 1-2 days with 1-3 day shipping.

We accept, .ai, .dwg, .dxf, .step. or .stp files. We have our Parts Builder available if you don’t have a file handy.

Choose your material, add your hardware, and adjust your quantity to see live pricing updates.

Standard production on hardware installation is 1-2 days with 1-3 day shipping.

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

Before you upload your design, take a look at our file preparation guidelines. They cover everything you need to know including file setup, sizing, supported formats, and tips for keeping costs down, so you can get the best results from your parts.

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

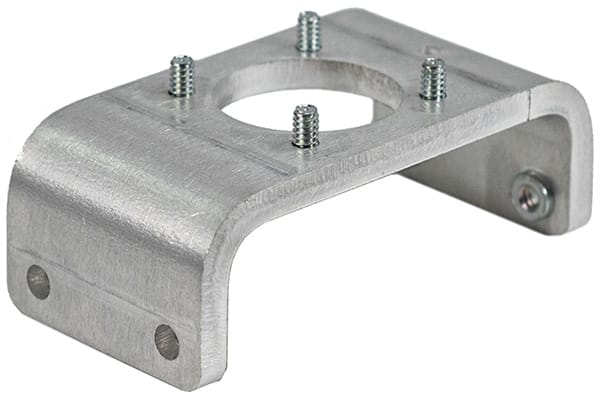

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 13 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 4 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+3-5 days | 10 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

Posted on

Top Quality Store

Please note: Pricing examples on our website are provided as general estimates and may not always reflect current prices. While we strive to keep these examples accurate, uploading your file is the best way to see instant current pricing.

Hardware is installed after bending, anodizing and plating, but before powder coating. Parts with both hardware and powder coating services will have the hardware capped/plugged before being powder coated. Check out the hardware guidelines page so you’ll know what to expect when you receive your parts!

All parts that have hardware installation included will need to meet certain size requirements in order to be manufactured correctly:

Min Part Size: 1” x 1.5”

Max Part Size: 36” x 46”

These are general size requirements for hardware insertion. Check the hardware catalog for each type of hardware below before submitting your order to make sure your parts meet all specifications.

Holes up to 4.00″ can be selected for hardware installation. When selecting holes for the desired hardware in your design, we will automatically resize the hole to the required size based on the hardware selected. The hardware SKU’s listed hole size in sheet (H) in the hardware catalog is the diameter the hole will be resized to.