Pricing and order information

Laser tube cutting services start from $39 USD per order. Save up to 70% with quantity discounts! We calculate quantity discounts based on several factors including material, density of cut features on each part, and number of duplicate parts. Our app will automatically provide discounted pricing for qualifying parts before checkout.

Materials available for laser tube cutting services

We offer tubes in round, square, and rectanglar shapes in the following materials:

- 6061 T6 Aluminum Tube

- 4130 Chromoly Steel Tube

- Docol Steel Tube

- A500 Mild Steel Tube

- A513 Mild Steel Tube

- 304 Stainless Steel Tube

Laser cut tube shapes and applications

Round tube

- Roll cages and chassis (motorsports, off-road)

- Handrails and guardrails

- Structural supports and braces

- Bicycle frames and furniture

- Exhaust tubing and fluid lines

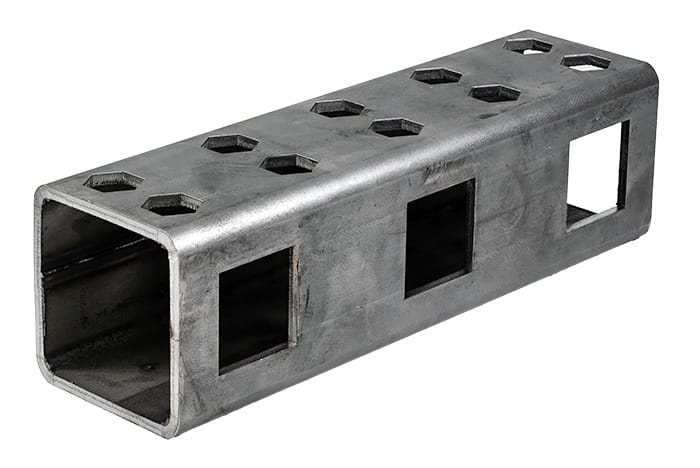

Square tube

- Frames for trailers, carts, and machinery

- Table bases and industrial furniture

- Fencing and gates

- Signposts and enclosures

- Welded steel structures

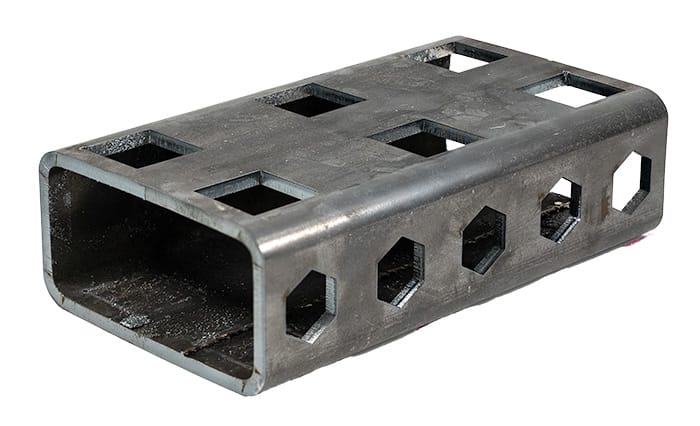

Rectangular tube

- Frame rails and subframes (automotive, trailers)

- Support beams and structural columns

- Racking systems and shelving

- Fabricated enclosures and frames

- Table legs and benches

Best file formats for metal tube cutting online

Files accepted for tube parts by our instant pricing system:

| AutoCAD | .step, .stp |

| Inventor | .step, .stp |

| Fusion | .step, .stp |

| SolidWorks | .step, .stp |

For tube laser cutting, we accept STEP and STP format 3D files. We recommend downloading one of our DXF or STEP files listed above to start your project using the correct profile for the tube material needed.

If there’s trouble uploading your finished file to our pricing system, please ensure your design meets all requirements listed in these guidelines.

File set up and design considerations

- Only include one part per file (no assemblies)

- Model full depth cut features that are perpendicular to the material surface

- Design your part in 1:1 scale using inch or mm units

- For rectangular steel tube, model an outside corner radius 3x the wall thickness

- For rectangular aluminum tube, model an outside corner radius .5x the wall thickness

- Design your model using our available cut profiles

- Connected cutouts should be bridged if needed to retain desired features

- Holes, cutouts, and bridging/webbing must meet minimum requirements

- Align tube models with the Y axis in your CAD software

- Don’t worry about kerf or weld compensation/normalization - we’ll handle it!

- No etching or engraving on tube materials

One tube part per file – no assemblies!

Files that include more than one model will not be processed correctly. Include only one part per file for accurate pricing and production.

Model standard 2D, full depth cut features

We offer standard laser tube cutting services, so all cuts must be modeled as full-depth features perpendicular to the material surface. We don’t provide multiaxis tube cutting or blind features.

Additionally, post processing is not available for tube stock at this time. Please do not model taps, countersinks, or other dimensional features we won’t be able to produce.

Set up tube parts in 1:1 scale, using inch or millimeter units

Design your parts exactly as you want them cut in 1:1 scale, using the same wall thickness as the tube stock you plan to order.

Our system recognizes inch and millimeter units only. Use either inches or millimeters when designing to ensure your overall part size is interpreted correctly.

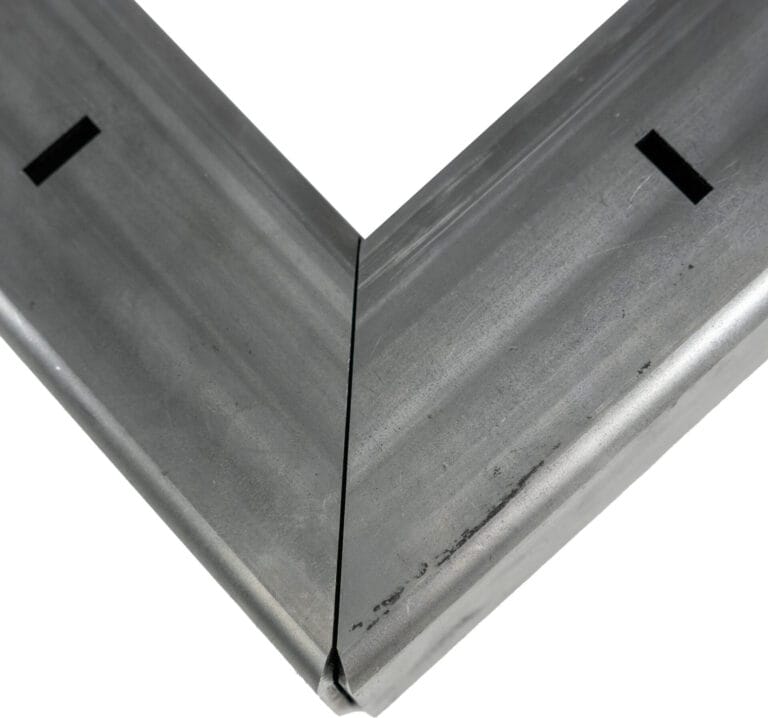

Square and rectangular tube external corner radii

Steel and stainless steel tube

For parts to be cut from steel or stainless steel rectangular or square tube materials, model the external corner radius at 3x the tube wall thickness. Then, offset the wall thickness to model the inside profile.

Please note, the actual external corner radius for square and rectangular steel tube stock will range between 1.5-3x the tube wall thickness.

Aluminum tube

For parts to be cut from aluminum rectangular or square tube materials, model the external corner radius at 0.5x the tube wall thickness. Then, offset the wall thickness to model the inside profile.

Download our tube profiles

Each tube material option has CAD files available to download with the tube profile found at the beginning of this page. We recommend starting your designs with our profiles to save time and get the most accurate parts possible.

Adjacent cutouts should be bridged if needed

We’re unable to include drop-throughs or scrap pieces that are cut out of your tube design, so think of your cut features like stencils and include bridging if needed. Bridging or webbing helps retain desired features in your final design.

Reference hole, cutout, and bridging/webbing specifications

Ensure all cut geometry meets the minimum requirements for the tube material you plan to order. All design specifications including minimum hole/cutout and minimum bridging/webbing size are listed in our material specs above.

Weld compensation (normalization)

At SendCutSend, we automatically normalize joints on all tube models so your parts will match up cleanly when it’s time to fasten or weld.

And don’t worry about kerf compensation – we’ll handle that automatically, too!

No etching or engraving

We do not offer cosmetic etching or engraving for any material at this time. Although we offer faint single line etching for part markings on select sheet metal materials, this special service is not available for tube stock.

What to expect from finished parts

Overall tolerance on cut features will be +/- 0.005”

Tolerance between cut features and non-cut features will be +/- 0.015”

There will be a slight conical taper present in the cut due to how tube is laser cut; the taper will be more noticeable in thicker materials and smaller diameter tubes

There will be dross and burr present inside tube parts from the cutting process

Non-extruded square and rectangular tube will have a weld seam on the inside of the tube

We do not perform post processing for tube parts at this time, so any desired dross, burr, or seam removal will need to be performed when parts get to you

If you design tabs and slots in your tube parts, the weld seam may land on a tab; this means you may need to file off the weld seam to achieve the desired fitment

We’re unable to guarantee part performance for end use; if your tube parts will serve a structural and/or load bearing function, observe best practices and standards for welding, assembly, and safety

Pre-flight checklist

- File is in a format that we accept for tube cutting (.step or .stp)

- Tube is modeled using our available tube profiles

- All cuts are perpendicular to the tube surface and full depth

- Only one tube part is present in your design file (no assemblies)

- File is built at a 1:1 scale in either inch or mm units

- For parts using square or rectangular tube, the external corner radius is modeled at .5x or 3x the material thickness, depending on the material

- Adjacent cutouts are bridged if needed to retain desired features

- All holes and cutouts meet the minimum size requirements for your desired tube material

- Tube model is aligned to the Y axis in your design

- No etching or engraving included in the design