You don’t need to compensate for kerf in your design. We’ll account for kerf on our end, so you can draw your parts with the dimensions desired. Be sure to factor in tolerances, though!

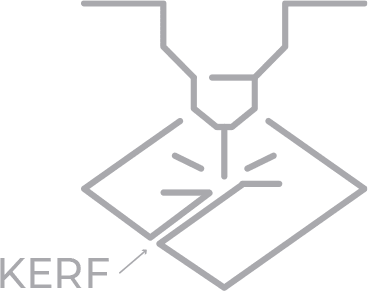

What is kerf?

Kerf is the additional material removed by the cutting tool in the machining process. Think of a saw cutting through a piece of wood. The saw cuts through the wood where you need it cut, but it also “pushes” aside some of the wood due to the width of the blade. That is “kerf.”

Laser cutter kerf is the width of the laser beam plus the small amount of additional material burned away by the heat. But be it a laser, waterjet, or CNC router, all machining processes have a small amount of kerf.

Don’t worry about kerf compensation; design parts exactly as you need them cut

You don’t need to compensate for the kerf in your design since we account for it on our end. Provided your design follows our laser, waterjet, or CNC routing guidelines, the kerf won’t affect your design at all. If you’d like to learn more, read our blog post on kerf in laser cutting.

Though you won’t need to compensate for kerf, you should keep tolerances in mind. Learn about cut tolerances, material tolerances, and bending tolerances! That way you can design accordingly before uploading your parts to our website for an instant quote.