Installation is easy. In a matter of three clicks you’ll be able to select materials, view live quotes and parts to your SendCutSend cart!

Our plugin is compatible with SolidWorks 2021 or newer versions.

SolidWorks is a robust tool for creating parts and prototypes. New to SolidWorks? We have plenty of tutorials to help.

After you login or create an account, you can upload your part via body, face, or sketch.

Our plugin makes material selection simple. We’ll detect the thickness of your part and provide a list of available materials that match.

We’ll show you live pricing quotes without ever leaving SolidWorks! Once you’re happy with your quote you may add parts directly to your cart with one click.

Additional services such as hardware, countersinking, and finishing options can be added from your cart.

Design and create cut files all in one place

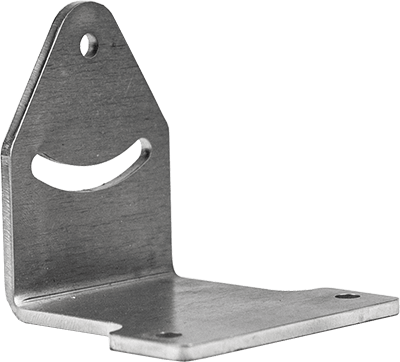

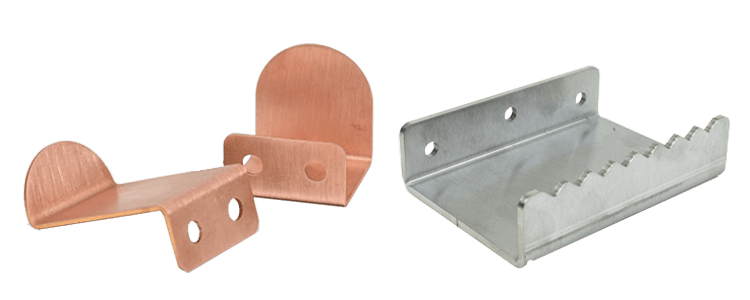

Easily design for laser cutting and waterjet cutting with sheet metal tools

Design specifically to the material you’ve selected from our library

Adjust K factor, bend radii, and more. Download our custom bend tables here

Easily connect with colleagues on projects and access other designers and engineers

Select materials, see live quotes, and order parts without ever leaving SolidWorks!

We have a variety of tutorials to help you get started building your SendCutSend project in SolidWorks

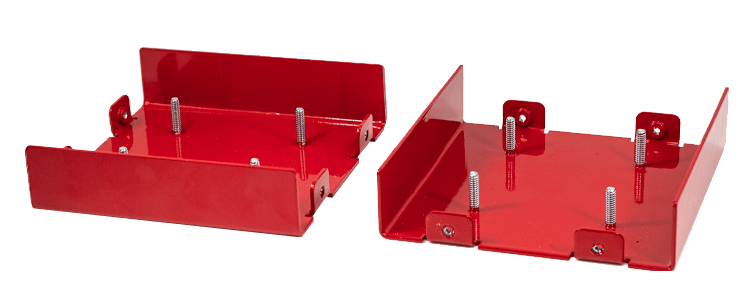

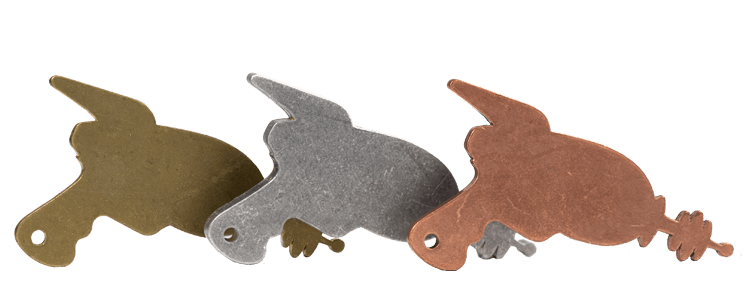

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

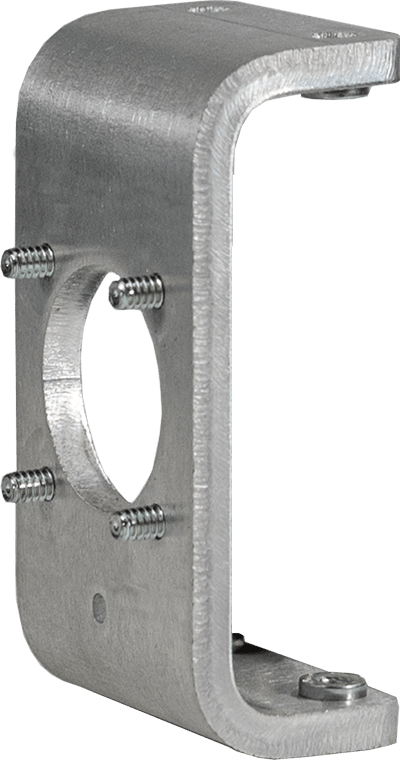

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

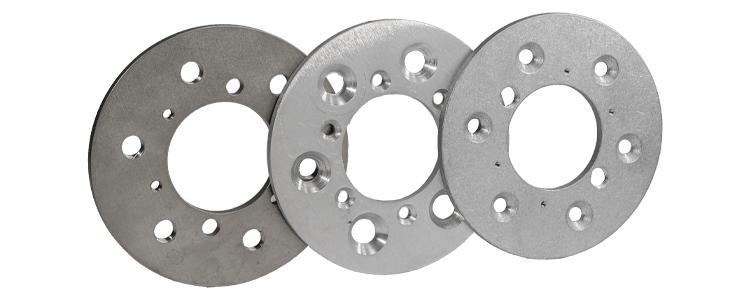

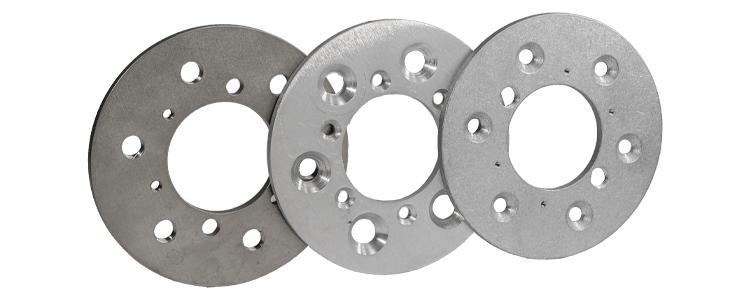

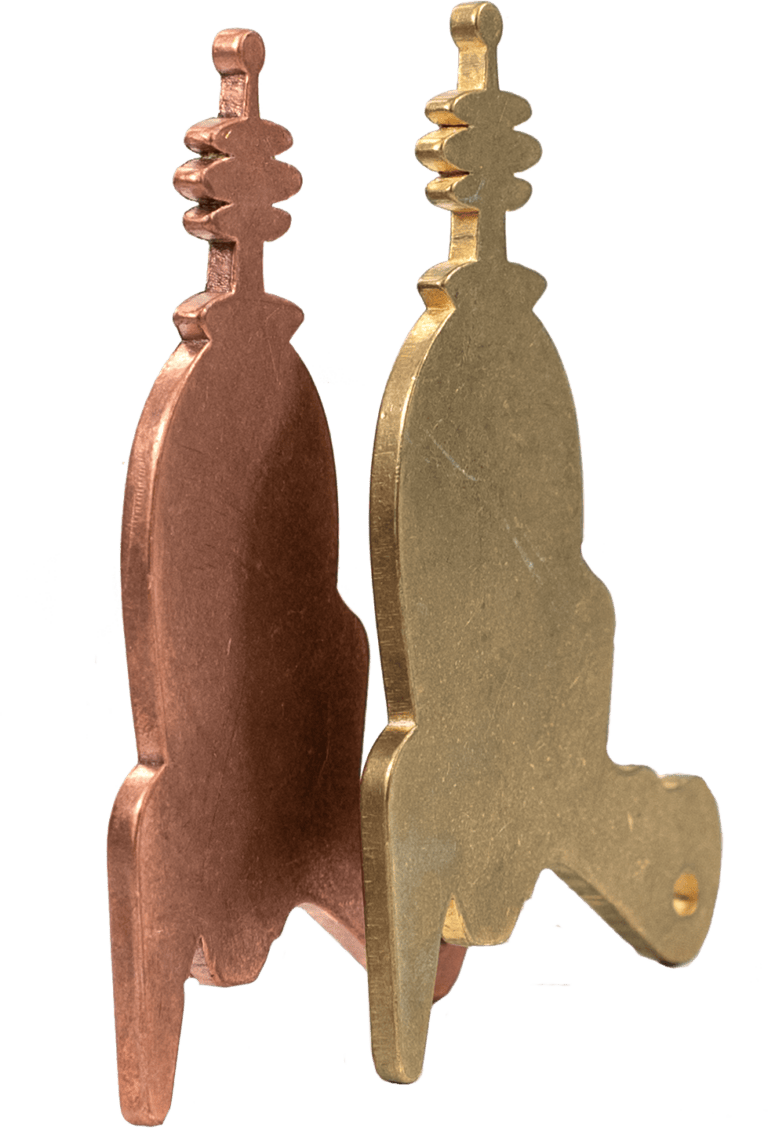

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

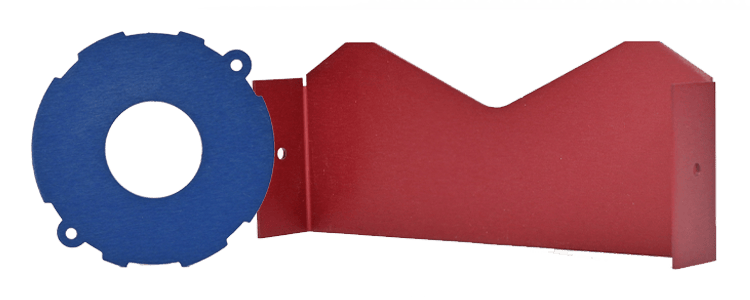

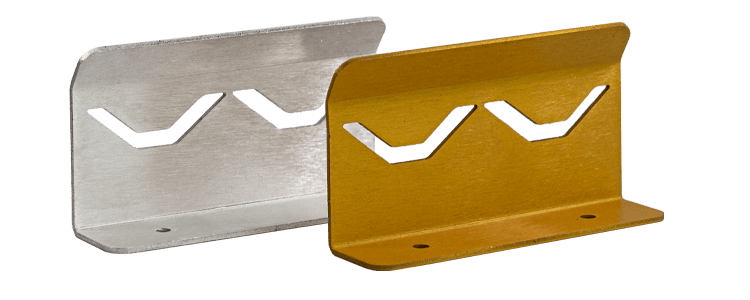

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

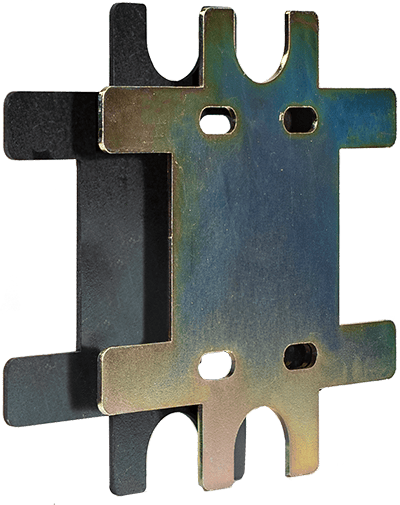

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.