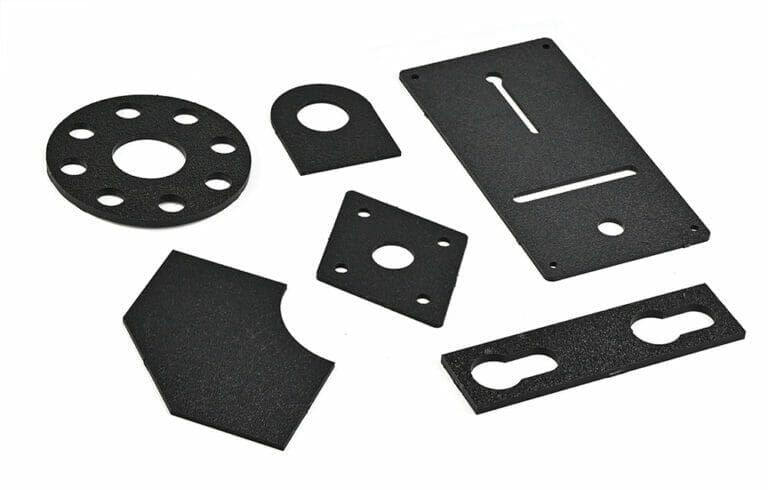

The low melting point of ABS lends itself to injection molding and 3D printing, and ABS is also a great candidate for CNC routing. Our custom cut ABS plastic parts are heat resistant, durable, and BPA free, making it a multi-purpose material with dozens of applications ranging from the food industry to aerospace engineering.

Instant quote

A: 1″ x 2″

B: 30″ x 44″

Custom quote

C: 30″ x 47″

.125″ (3.18mm)

.187″ (4.75mm)

.234″ (5.94mm)

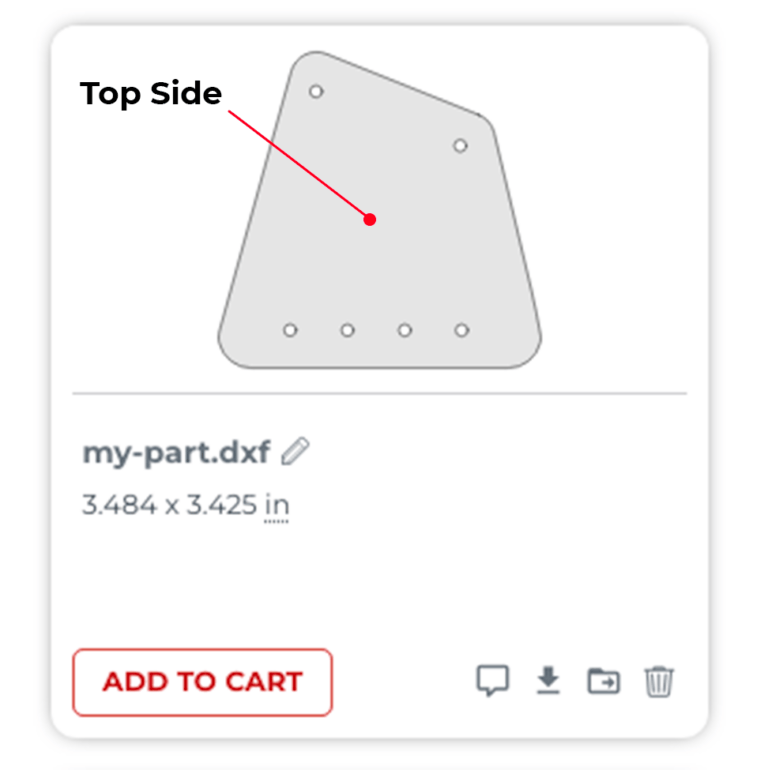

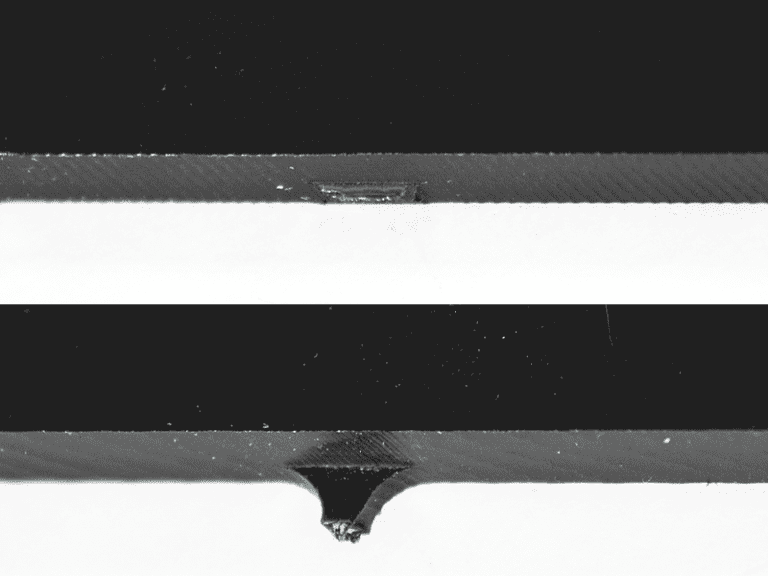

Please note (especially for mirroring parts), the finishes on the front and back of ABS plastic differ. The top side is textured and the back will be glossy. We will cut your file texture side up.

The orientation of your part as shown in the part preview will be considered the top side.

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

ABS plastic is a sturdy thermoplastic that is often used in prototyping due to its low cost and high strength-to-density ratio. With a tensile strength of 4,100 psi, ABS parts are well-suited for high stress applications that require a low weight material.

Outside of prototyping, ABS plastic parts are most commonly used in dashboards, seat backs, and instrument paneling in the automotive and construction industries.

As with most plastics, you need to protect your custom ABS parts from high-heat situations due to its low continuous operation temperature (about 150 degrees F). In the right application, however, this lightweight and low-cost plastic can bring a new kind of strength to your project.

Be sure to read up on our design guidelines for CNC routing materials as the tooling requirements are different from laser cutting.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.