Delrin® 150 is the answer to a host of problems in the manufacturing industry. If you need a part that’s abrasion-resistant, strong, stiff, chemical resistant, moisture resistant, has solid dimensional stability, and is still machinable, Delrin® 150 is the material for you.

Delrin® 150 is the perfect middle ground between metal and plastic. Our Delrin® 150 is what’s known as an acetal class material. This means that it’s suitable to be used with lubricants and solvents, like gasoline, without any decline in performance. Often used in applications where exposure to wear and extreme moisture is guaranteed, it provides superior strength in areas where metal would be an unwise choice.

You can consider Delrin® the bridge between metal and plastic, offering a host of useful properties that many metals just can’t deliver. A unique fit for robotics, automotive, and in some cases aerospace applications, Delrin carries with it a high creep strength, meaning Delrin® can handle repeated loading without deformation. This makes it a great material for bushings and gears that need to be sturdy enough to withstand impacts, but also lightweight enough to fit project constraints.

In addition to being receptive to fastening applications, our custom cut Delrin® is also especially machinable, making it the go-to thermoplastic for parts that require tight tolerances and more intricate geometry.

Overall, our custom cut Delrin® parts are positioned for specialized applications that require properties of both plastics and metals to get the job done.

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

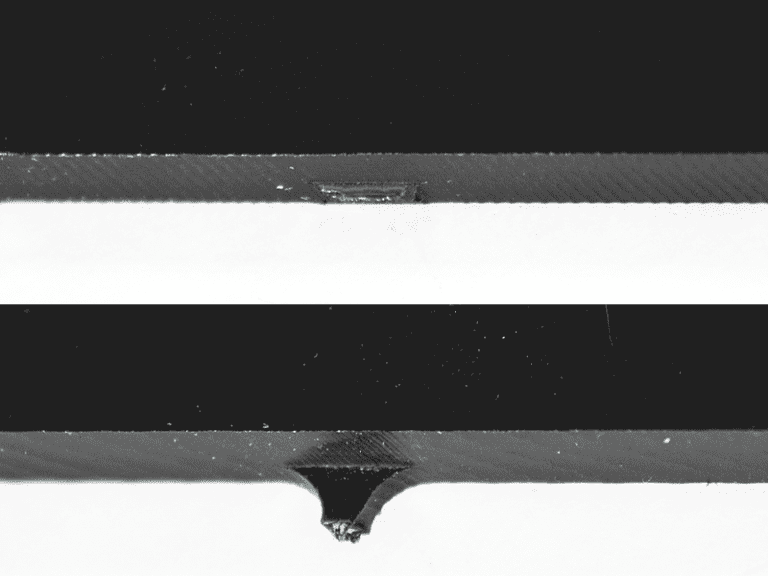

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

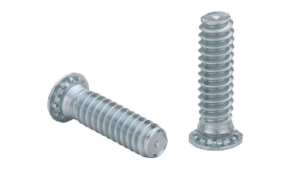

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

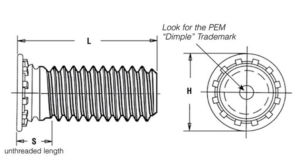

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |