You might know it as plexiglass, but SendCutSend’s laser cut acrylic plastic is here to meet the expanding needs of your projects. Our cast acrylic laser cutting service includes several colors and thicknesses. Parts are often used for display panels, equipment enclosures, templates and prototypes.

A: .187″ x .375″

B: 30″ x 44″

.118″ (3.0mm)

.177″ (4.5mm)

.214″ (5.4mm)

Transparency and translucency of our acrylic varies by color. If the amount or quality of light transmission is important for your project, we recommend ordering sample pieces to confirm if specific acrylic colors will work for your application. Colored and mirrored acrylic is available in the .118″ sheet thickness.

Your acrylic parts will come with a removable film on each side to protect them during handling and transit. Your parts may come with different films, even if they are duplicates of the same part.

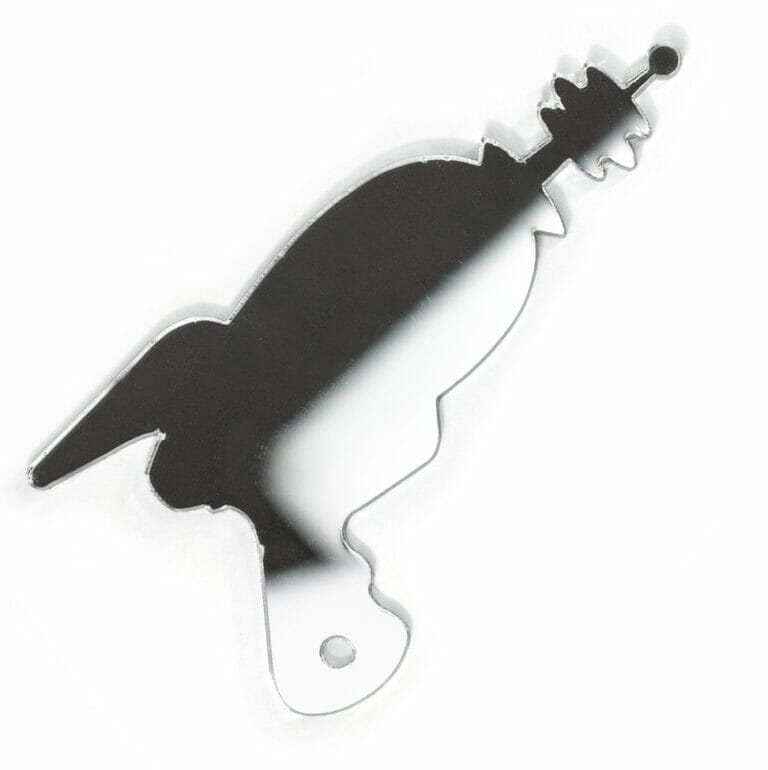

Mirrored acrylic will only have a protective film on the front side, while the back side is dull grey. We will cut your part mirrored side up. Our mirrored acrylic creates a true mirror without blur. The material is completely opaque.

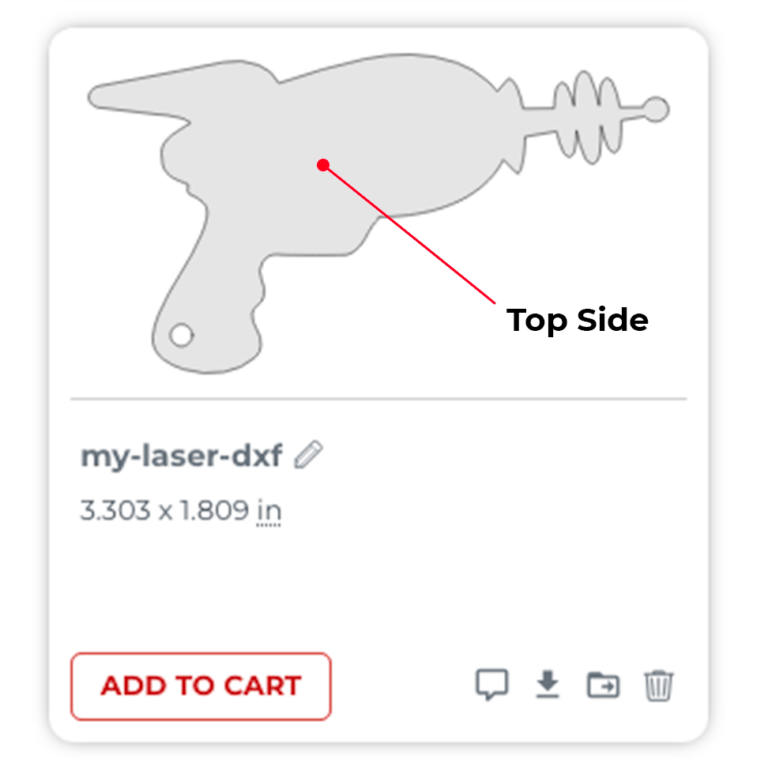

The orientation of your part as shown in the part preview will be considered the top side.

We like to refer to Acrylic as the wonder plastic. Originally used in World War II for airplane windows and canopies, acrylic has evolved to a plethora of new usages. Thanks to its exceptional strength-to-weight ratio, versatility, and weather resistance, acrylic has found success across many industries.

Acrylic is typically about 10 times more resistant to impact than standard glass.

Whether diffusing light in modern fixtures or offering protective barriers in medical settings, acrylic’s versatility shines through, rendering it a material of choice in numerous applications worldwide. Its innate properties, including optical clarity, lightweight nature, and exceptional durability, make it an ideal choice for a myriad of purposes.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Acrylic in three thickness options: .118″ (3.0mm), .177″ (4.5mm), and .214″ (5.4mm).

When ordering custom Acrylic parts through SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is .187″ x .375″, while the largest part supported is 30″ x 44″.

You can add the following services to your Acrylic parts:

Laser Cutting