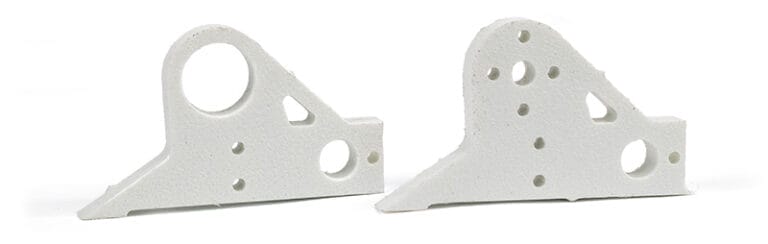

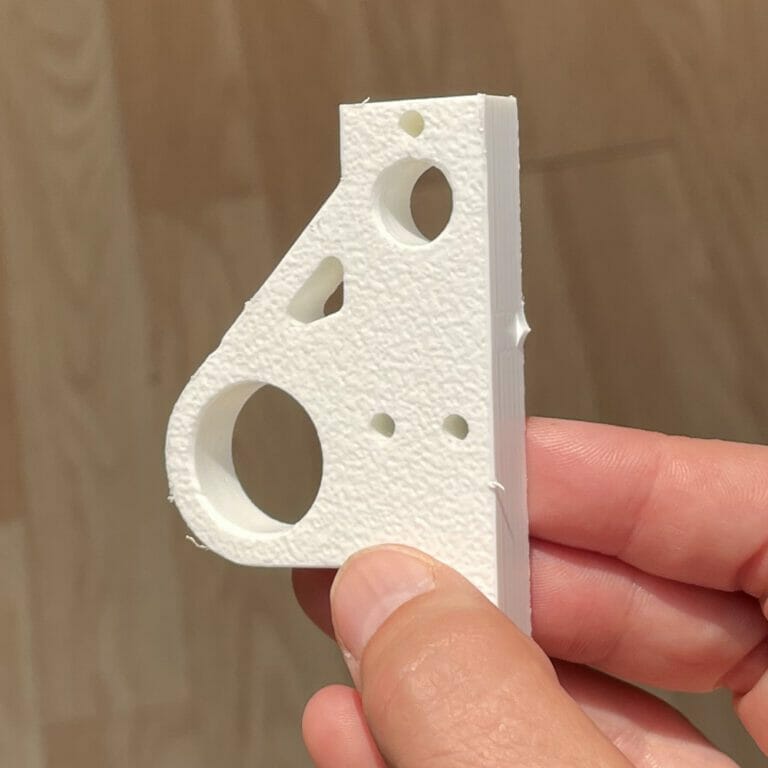

Sometimes called marine board, HDPE plastic is petroleum-based and suitable for myriad applications where impact resistance and low moisture absorption are critical to structural integrity. This easily moldable material has a staggering list of usages from medical to nautical. You can expect a textured finish on both sides of HDPE.

Commonly used as an alternative to wood in harsh environments.

HDPE (High-Density Polyethylene) is a thermoplastic that belongs to the polyolefin group of materials and is commonly used as a replacement for wood in marine applications. Sometimes you’ll hear it referred to as “plastic lumber” because of its excellent impact resistance, low moisture absorption, and high tensile strength.

This material is lightweight but tough, making it great for applications such as marine surfaces and bulkheads, industrial containers, structural components, and washers. And if that wasn’t enough, it’s especially useful in marine applications because of its non-toxic and non-staining nature.

HDPE boards are long-lasting, low maintenance, and safe, making them a healthy addition to your project. Resistant to molds, mildew, and other forms of rot, this material is uniquely suited for conditions where water transport or exposure are major factors. It’s able to be effectively sterilized and as such is used in many food and beverage applications. Wildly enough, this petroleum-based plastic is even used in reconstructive surgeries.

Water isn’t the only liquid this material is compatible with. HDPE is a great choice for use with the most common chemicals, solvents, acids, detergents, and cleaning fluids. And if you’re still not sold, it’s easily recycled, has an amazing strength-to-density ratio, and has extreme corrosion resistance.

The best part? You don’t need to know how to cut it, we’ll take care of that for you.

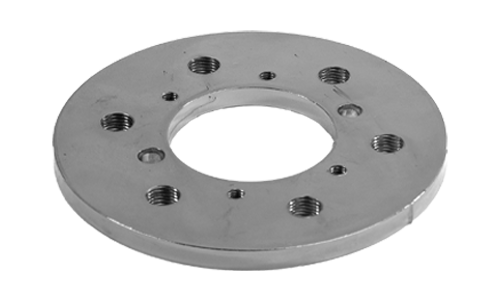

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Click below to learn what to expect and how to best design with these tabs in mind.

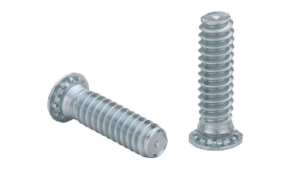

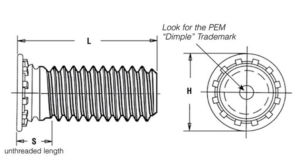

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |