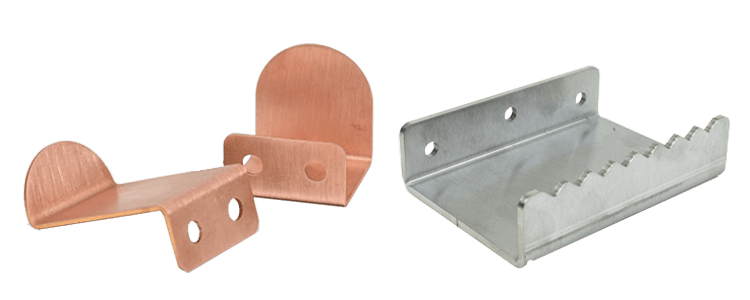

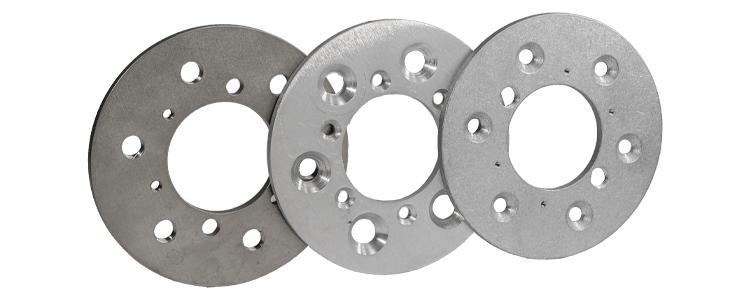

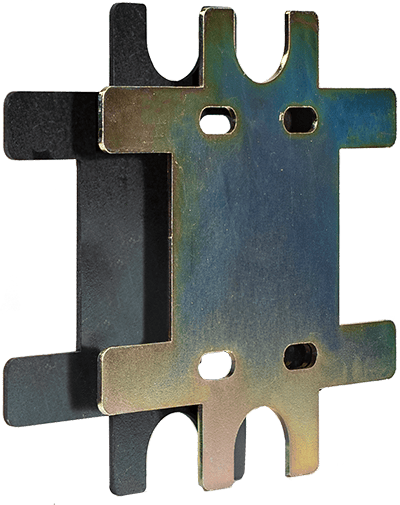

Size: 3.5″ x 3.5″

Laser Cutting, Tapping, Powder Coating

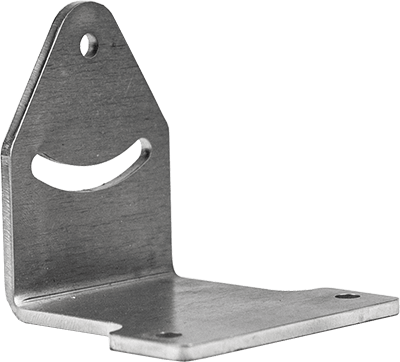

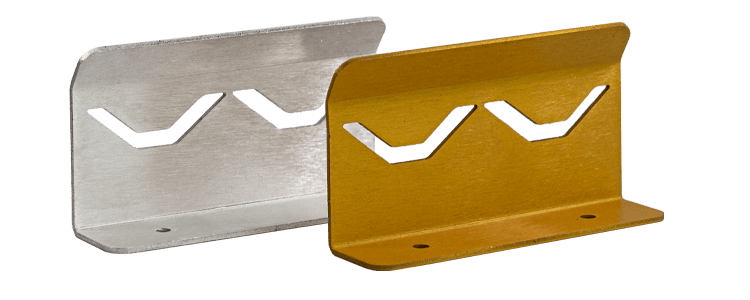

Size: 7.5 x 4.5″

Laser Cutting, Powder Coating, Deburring

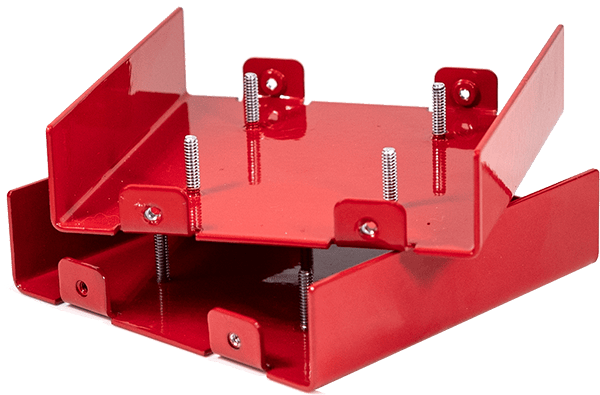

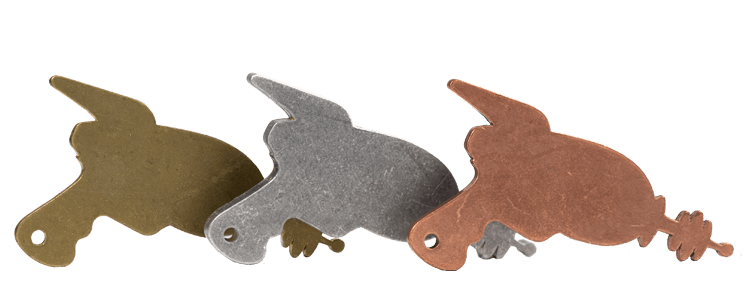

Size: 4.8 x 5.8″

Laser Cutting, Bending, Hardware, Powder Coating

We accept .ai, .eps, .dwg, .dxf, step, and .stp

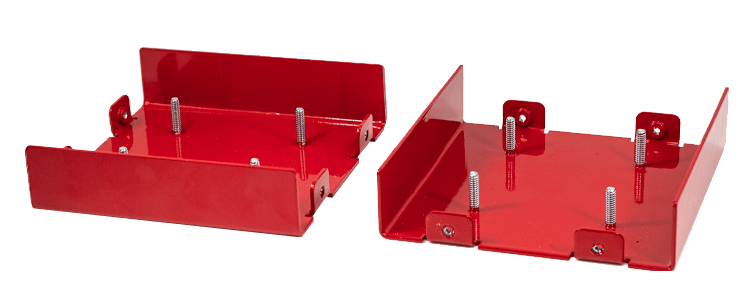

7.5 x 4.5″

Laser Cutting, Powder Coating, Deburring

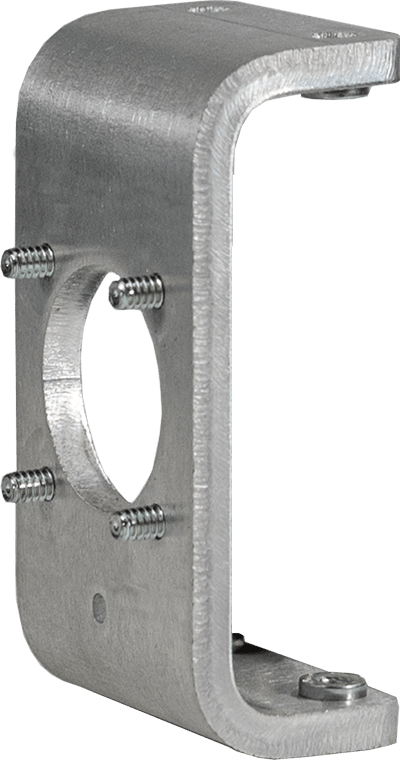

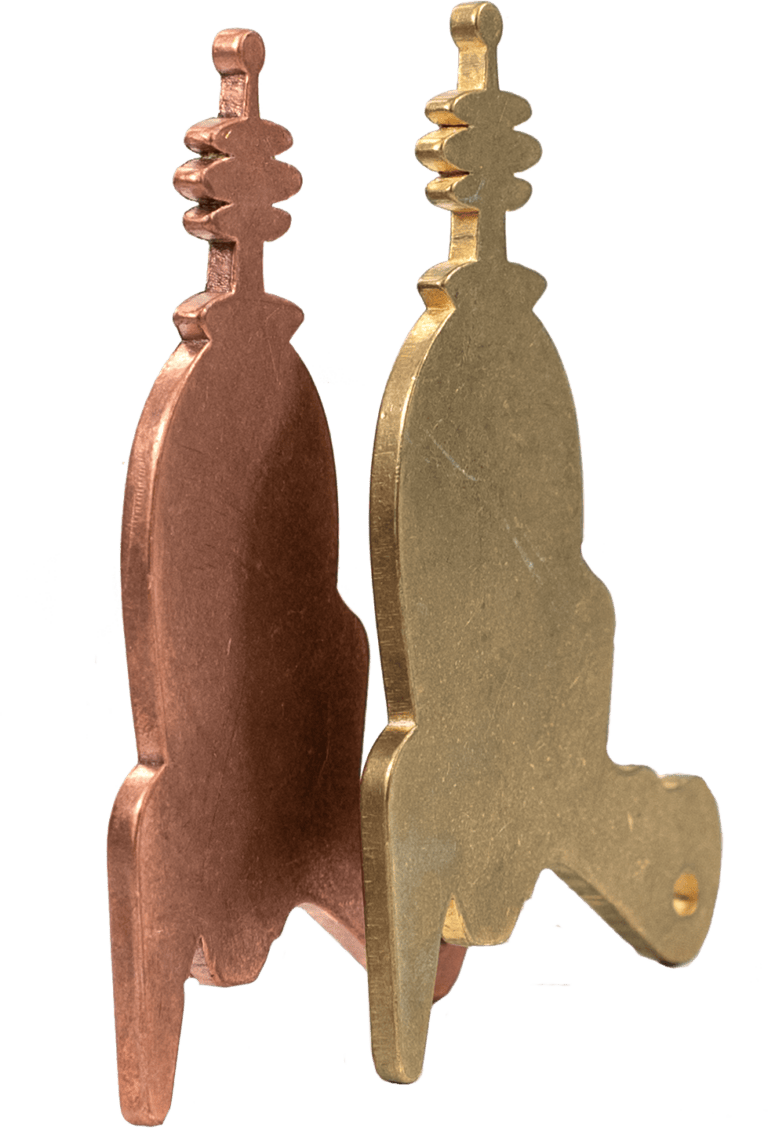

3.5″ x 3″

Laser Cutting, Tapping, Powder Coating

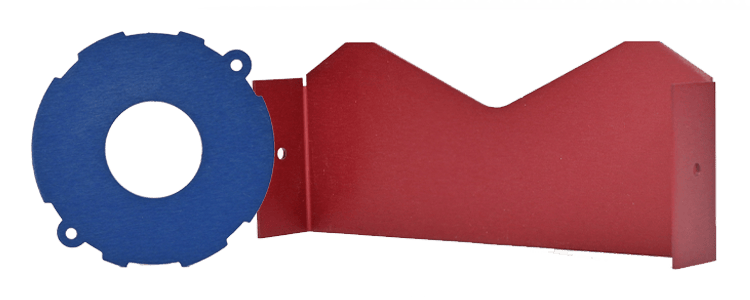

4.8 x 5.8″

Laser Cutting, Bending, Hardware, Powder Coating

Powder coating is one of the strongest finishes available. It’s impact, chemical, and weather resistant. To prove just how durable it is, we put some of our powder coated materials to the test.

Black Magic/BK120

0-9% Gloss

Cardinal BK 12/(RAL 9011)

90% Gloss

Cardinal BK176

10% Gloss

Gun Metal 59/95726

75% Gloss

138/70046(RAL 7040)

87% Gloss

Tiger Bengal White

149/11111/(RAL 9003)

90% Gloss

149/42280/(RAL 5010)

85% Gloss

149/52900/(RAL 6001)

85% Gloss

Cardinal RD03/(RAL 3002)

90% Gloss

YL01/(RAL 1018)

90% Gloss

“Truly incredible stuff. The quality of work was top-notch. The powder coat finish turned out awesome. They even shipped the parts in fantastic vacuum-packed containers to keep them looking perfect in transit. Truly couldn’t be happier.”

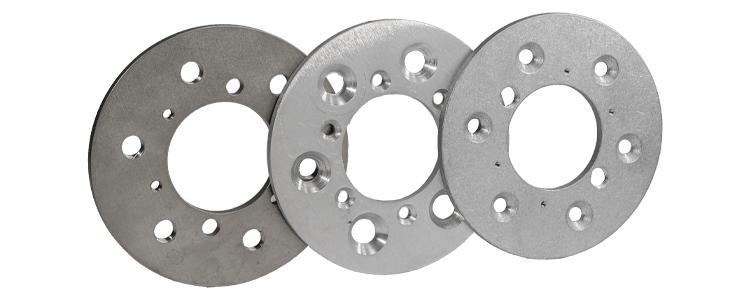

If a material can hold an electrostatic charge and withstand heat, it can be powder coated. SendCutSend currently offers several grades of aluminum, steel, and stainless steel for our in-house powder coating.

Powder coating is a durable and aesthetic finishing process used to protect and elevate your SendCutSend projects. We’ve made adding powder coating as simple as a click of the mouse.

Making sure your file meets our requirements will ensure you get your parts as quickly as possible.

Making sure your file meets our requirements will ensure you get your parts as quickly as possible.

Select your material, powder coating color, and quantity to see live pricing and shipping updates.

We accept, .ai, .dwg, .dxf, .step. or .stp files. We have our Parts Builder or Designs Services available if you don’t have a file handy.

Standard production on powder coated orders is 7-10 days with 1-3 day shipping.

We accept, .ai, .dwg, .dxf, .step. or .stp files. We have our Parts Builder or Designs Services available if you don’t have a file handy.

Select your material, powder coating color, and quantity to see live pricing and shipping updates.

Standard production on powder coated orders is 7-10 days with 1-3 day shipping.

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

Top Quality Store