4130 Chromoly steel is a low carbon alloy steel (Chromium and Molybdenum) that excels in structural applications and welding, along with many other high-stress, high-performance projects.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 56″

.050″ (1.27mm)

.063″ (1.60mm)

.125″ (3.18mm)

.190″ (4.83mm)

.250″ (6.35mm)

Stress cracking is common and unavoidable when bending 4130 Chromoly, especially at thicknesses of .125″ and greater.

4130 Chromoly steel is a durable metal meant for long-lasting projects. If what you’re making needs to withstand extreme pressures and temperatures over time, Chromoly might be the metal for you. The reason for this is in one of its key properties: Creep Strength.

When you use this material in high-stress applications, you can be sure that it will stay in place and hold its shape for longer. Hence why it’s often used in bicycle frames, roll cages, and airplane structures all over the world.

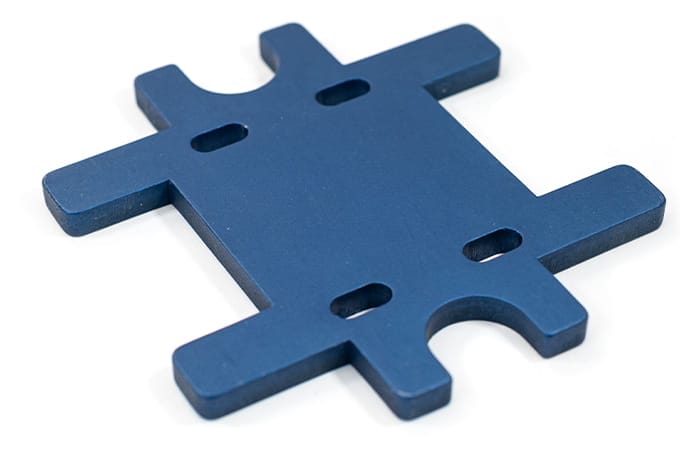

If you’re looking at something a little smaller, like a gear or cog. 4130 Chromoly steel’s excellent heat treatability and machinability make it an ideal fit for strong, tiny parts.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

This material comes in five available thicknesses: .050″(1.27mm) .063″(1.60mm), .125″(3.18mm), .190″(4.83mm), and .250″(6.35mm).

SendCutSend offers 4130 Chromoly with clearly defined size and thickness options. Instant quoting is available for parts measuring between .25″ x .375″ and 30″ x 44″, while custom quotes can accommodate larger dimensions up to 30″ x 56″.

You can add the following services to your 4130 Chromoly parts:

Bending, Plating, Powder Coating, and Tumbling