Heat Wave. Deep Heat. Heat of the Night. While heat makes for a good song lyric, in fabrication it’s a different story. Excess heat is something most metalworkers and engineers would prefer to avoid—especially when cutting precision parts out of sheet metal.

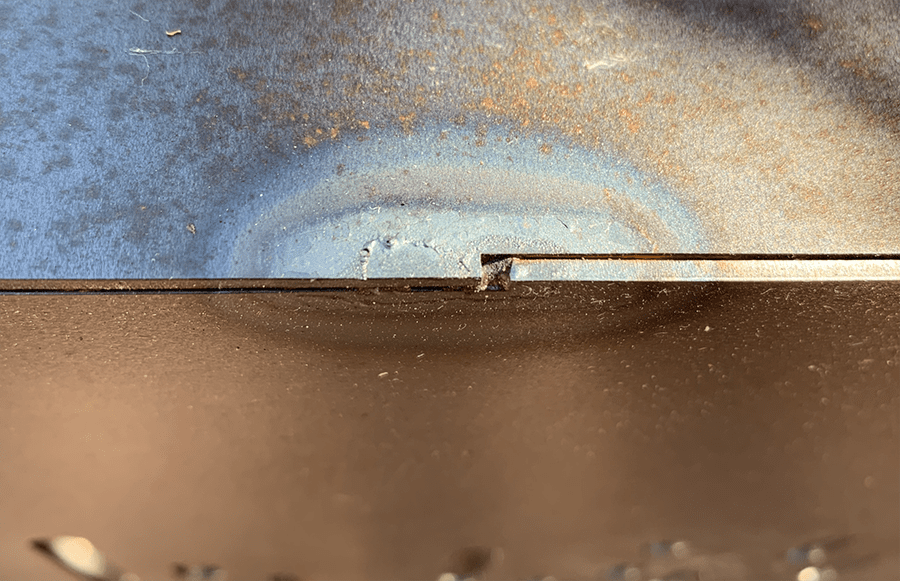

That’s because high heat creates what’s known as HAZ on metal parts, or the heat-affected zone. If you’ve ever noticed rainbow discoloration on a welded piece or seen brittle cracks form around a cut edge, you’ve seen the effects of HAZ firsthand. In some cases it’s just cosmetic, but in others it can weaken the part and shorten its lifespan. Let’s break down what HAZ is, why it matters, and most importantly, how you can avoid it in your custom parts.

What is HAZ on Metal Parts?

The heat-affected zone (HAZ) is the portion of metal near a weld or cut line that’s been altered by intense heat, but not melted outright. Think of it as the “collateral damage” zone caused by a thermal process.

When metal is exposed to heat above its transformation temperature, the internal microstructure rearranges itself. Once the heat source moves on, that altered microstructure remains—leading to new mechanical properties in that zone.

Typical signs of HAZ include:

- Discoloration: The rainbow or straw-colored hues often seen around welds.

- Localized hardening: The metal becomes tougher in that small region, but also harder to form.

- Brittleness: Sometimes HAZ makes the material more prone to cracking (hydrogen embrittlement).

- Reduced corrosion resistance: Stainless steel, for example, can lose its protective qualities if overheated.

While these changes might sound minor, they can have serious consequences. For aerospace components, HAZ in turbine blades has been directly linked to in-flight engine failures. For everyday parts, HAZ can make welding, bending, and finishing more difficult.

Why HAZ is a Problem in Sheet Metal Laser Cutting

In sheet metal fabrication, precision and reliability are everything. Whether you’re making brackets, enclosures, or decorative signage, the structural integrity of your parts matters. HAZ undermines that by creating zones of unpredictable strength.

- Weakened parts: Edges may crack under stress.

- Tougher fabrication: Parts may resist bending or warp during welding.

- Finishing headaches: HAZ often leaves behind oxidation or discoloration that must be cleaned before powder coating, anodizing, or plating.

In short: if your goal is to produce accurate, professional-quality parts, minimizing HAZ is key.

Which Processes Cause the Most HAZ?

Not all cutting methods create the same level of HAZ. It comes down to two things: temperature and cutting speed. The hotter and slower the process, the more HAZ is created.

Here’s a quick comparison:

- Oxy-fuel cutting: Extremely high heat, very slow process → large HAZ.

- Plasma cutting: Fast but still high-heat → moderate HAZ.

- Laser cutting: Precise, concentrated beam → minimal HAZ.

- Waterjet cutting: Cold process, no heat involved → zero HAZ.

This is why modern fabricators lean heavily on laser cutting for metals and waterjet cutting for sensitive or composite materials. Both processes strike the best balance between accuracy, speed, and HAZ reduction.

How to Avoid or Minimize HAZ

So what can you do if you want to avoid HAZ on metal parts? Here are the best strategies:

1. Choose the Right Cutting Method

- Laser cutting is the best choice when you want precision and minimal HAZ. A focused beam cuts fast and keeps the heat localized.

- Waterjet cutting is the gold standard for avoiding HAZ completely, especially on thick, sensitive, or composite materials.

- Mechanical cutting (shearing, punching, nibbling) also avoids HAZ but has limitations in part geometry and thickness.

2. Optimize Cutting Parameters

Even within laser cutting, the way a part is cut matters:

- Faster cutting speeds = less heat transfer.

- Smaller beam diameters = narrower HAZ.

- Using nitrogen assist gas = cleaner, oxide-free edges.

3. Consider Post-Processing (When Necessary)

Techniques like solution annealing can help restore a material’s properties after heat exposure, though they are rarely practical for large batches or oversized parts. It’s usually smarter to minimize HAZ at the source rather than try to fix it later.

SendCutSend’s Approach to Reducing HAZ

At SendCutSend, we’ve built our cutting services around minimizing or eliminating HAZ so you can trust your parts to perform as designed.

- Our industrial laser cutters handle carbon steel, stainless steel, aluminum, copper, brass, titanium and more with minimal heat-affected zones.

- For parts where HAZ is completely unacceptable, our abrasive waterjet cutting delivers accurate results with no thermal distortion.

- Depending on the metal, we can cut up to ½” thick and offer secondary services like bending, powder coating, anodizing, and plating—so your parts are ready to assemble.

When you upload a design to our platform, our system automatically chooses the best process for your project based on material, thickness, and geometry. That way, you don’t need to stress about whether HAZ will affect your final parts.