From insulated roofing to heat sink in your PC to HVAC systems, copper is found in dozens of applications. High-quality laser cut copper improves any project, whether it’s functional or purely aesthetic.

A: .25″ x .375″

B: 30″ x 44″

.040″ (1.02mm)

.063″ (1.60mm)

.125″ (3.18mm)

.187″ (4.75mm)

.250″ (6.35mm)

Our C110 half-hard copper is classified as electrolytic copper, which basically means it’s an extremely high purity (greater than 99% copper, ours is 99.9%). For your projects, this means that the material’s electrical properties won’t be hampered by any erroneous leftover elements. You’re getting one of the purest grades available.

Copper, only surpassed by silver in its electrical properties, is perfect for hospital settings due to its antimicrobial nature. In diagnostic equipment, you’ll find this material assisting in transmitting signals for examination and providing the necessary structure in small, vital implants.

Send us your design and we’ll help you manufacture the highest-quality busbars, heat sinks, connectors and more.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

Choose from five thicknesses including .040″(1.02mm), .063″(1.60mm), .125″(3.18mm), .187″(4.75mm), and .250″(6.35mm).

Copper is available at SendCutSend with a range of thicknesses and part sizes. Instant quotes are possible for dimensions between .25″ x .375″ and 30″ x 44″.

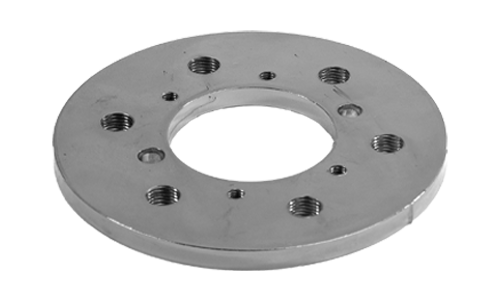

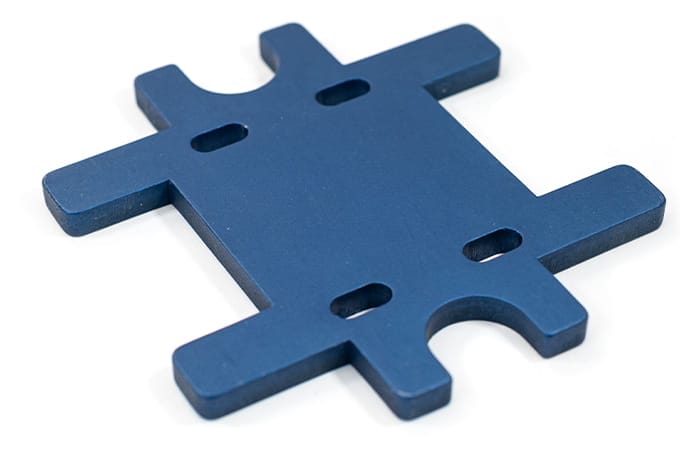

You can add the following services to your Copper parts:

Bending, Deburring, Plating, Tapping, and Tumbling