CAD or Computer Aided Design tools are used on nearly every level of design, from occasional hobbyists making things in their free time, to teams of engineers and designers working for billion dollar companies. With CAD you can quickly iterate a 3d design before the first prototype without wasting a ton of time and materials in fabrication. You can visualize the scale of the project. You’re able to test for fit and clearance between components before the parts have been made. You can clearly document a complex design to share with third party manufacturers or sell as a set of plans for others to make themselves. If you’re using some kind of CNC fabrication method (3D printing, laser cutting, CNC machining, etc.) to make your own designs then 3D is going to be a necessity for all but the most basic parts. There are a lot of benefits to using CAD software to develop your design.

The key to getting the most out of CAD is to choose the right software for you and your projects. In this article we want to compare two of the most popular 3D CAD software packages to help you decide which one might fit your projects best. Today we’re going to be discussing SolidWorks by Dassault Systèmes and Autodesk Fusion by Autodesk.

Some readers may be hesitant to try 3D CAD because it looks overwhelming, but SendCutSend has put together a number of tutorials for several different CAD programs. You can check them out on our blog.

Note for Future Readers

Before we get started, it’s important to note that the world of 3D CAD software is a competitive industry. As with any good software, it’s constantly being updated and improved. So it’s possible features that are missing from one software at the time of this writing get added at a later date. Both Dassault and Autodesk use feedback from their user community to fix bugs, improve existing functionality and develop new tools and features.

For the absolute latest information on either of these two options, check out their websites directly.

SolidWorks vs. Autodesk Fusion: Main Differences and Similarities

Both SolidWorks and Autodesk Fusion are great 3D CAD options from companies that have been in the 3D CAD industry for decades. It will be the features you need for your projects that make one a better choice for you specifically. They have a lot in common and share a lot of fundamental features, but they also each have some unique capabilities making them stand out.

Let’s take a deeper look at these two powerful CAD software packages.

Autodesk Fusion vs SolidWorks: Overview/General Use

Both Autodesk Fusion and SolidWorks include a similar fundamental set of 3D CAD modeling tools for mechanical design. Both include the ability to increase their capability by adding on specialized components. In Fusion these are called extensions, in SolidWorks they’re known as add-ons. These include more advanced simulation tools, file management, manufacturing, electrical integration, visual rendering and so on.

Autodesk Fusion has a slightly greater focus on new users, offering access to a lot of different capabilities. It has become extremely popular with hobbyist makers and small companies, no doubt because of its low cost for the range of functionality it can provide. We’ll discuss cost and features in more detail later in this article. It is still used by more advanced users, but doesn’t quite have the depth (more complex features) compared to SolidWorks.

SolidWorks focuses more on advanced mechanical design features. Advanced features don’t necessarily make it possible to create better designs, but they do help to streamline the design process. SolidWorks tends to be used more by professional designers and engineers.

Summary: You can think of Autodesk Fusion as offering a wider range of features in its most basic package, without as much depth in each feature. Where SolidWorks doesn’t offer the same number of modules in its base package, but it does provide much more depth in the functions it does offer.

Autodesk Fusion vs SolidWorks: Performance

Specific system requirements change with each new version of the software released, so we won’t include those details here. What we will say is that either software can run on fairly minimal hardware, but your machine specs will greatly impact how well either SolidWorks or Autodesk Fusion can handle larger, more complex designs.

Autodesk Fusion is a little lighter duty than SolidWorks, so you may notice it starts to slow down as designs become more complex. That could mean a lot of complex features or it could mean dozens of components and joints. With decent computer specs, it should handle multiple dozens of components easily. Autodesk Fusion also has the advantage of being able to run on MacOS or Windows so you’re in luck no matter which operating system you use (sorry Linux users).

SolidWorks is built to handle more complexity and larger assemblies and even includes tools for users to see the most resource intensive areas of their designs and optimize for them. SolidWorks will only run natively on Windows, but there are workarounds if you’re a Mac user and need to use SolidWorks.

Summary: With good computer specs, either software will handle moderately complex designs, but if you need large assemblies or more detail, SolidWorks is the better choice. If you’re a Mac user, go with Autodesk Fusion.

Autodesk Fusion vs. SolidWorks: Import/Export

Nearly all software has its own file formats it uses to store files natively, but being able to import and export files between software can be particularly useful. Both Autodesk Fusion and SolidWorks can import and export the most commonly used generic 3D CAD formats:

- .step

- .iges

- .dxf – useful for sending designs to SendCutSend

- .stl

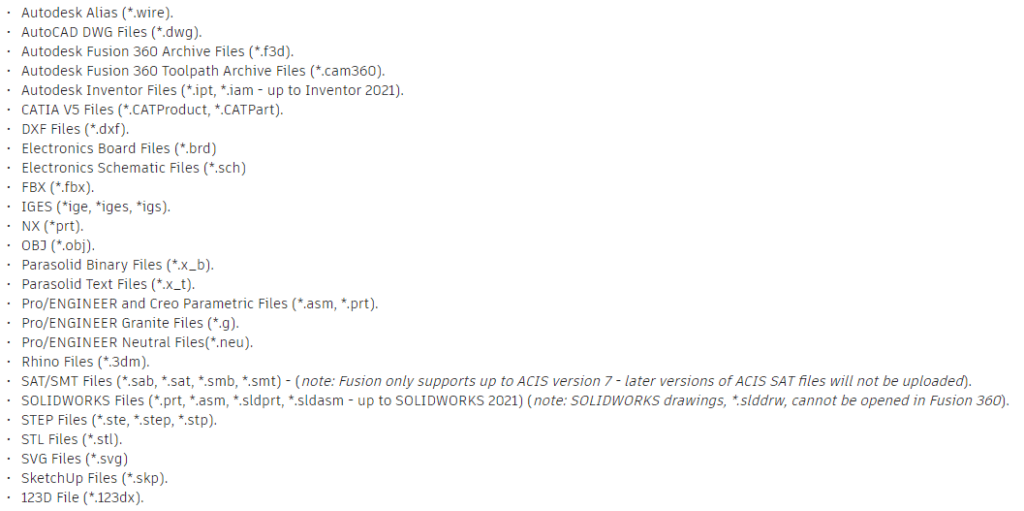

Autodesk Fusion importable file types:

Autodesk Fusion exportable file types:

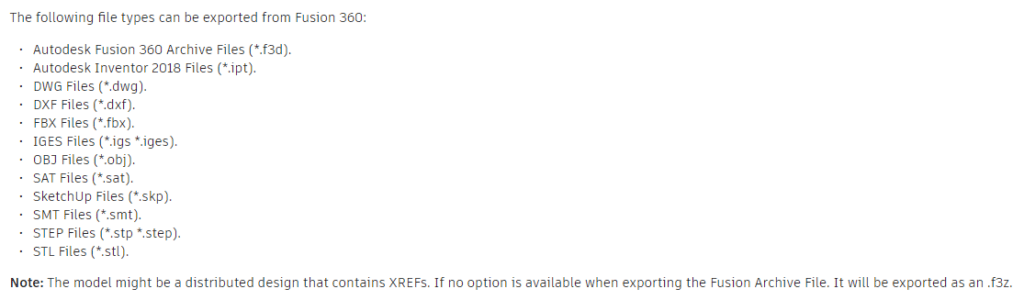

SolidWorks importable and exportable file types:

If you’re exporting your design for SendCutSend from Autodesk Fusion or SolidWorks, we require a DXF file. We’ve got detailed instructions on how to export a DXF from both of these softwares on our blog and YouTube Channel.

4 Ways to Export a DXF from Autodesk Fusion

Exporting to DXF from SolidWorks

Autodesk Fusion vs SolidWorks: User Interface

Most 3D CAD software has a similar user interface with an area to see the model surrounded by various tools. That’s even more the case when they are both focused primarily on mechanical design like the two we’re comparing here. The phrase “if you’ve seen one, you’ve seen them all” holds true with these two.

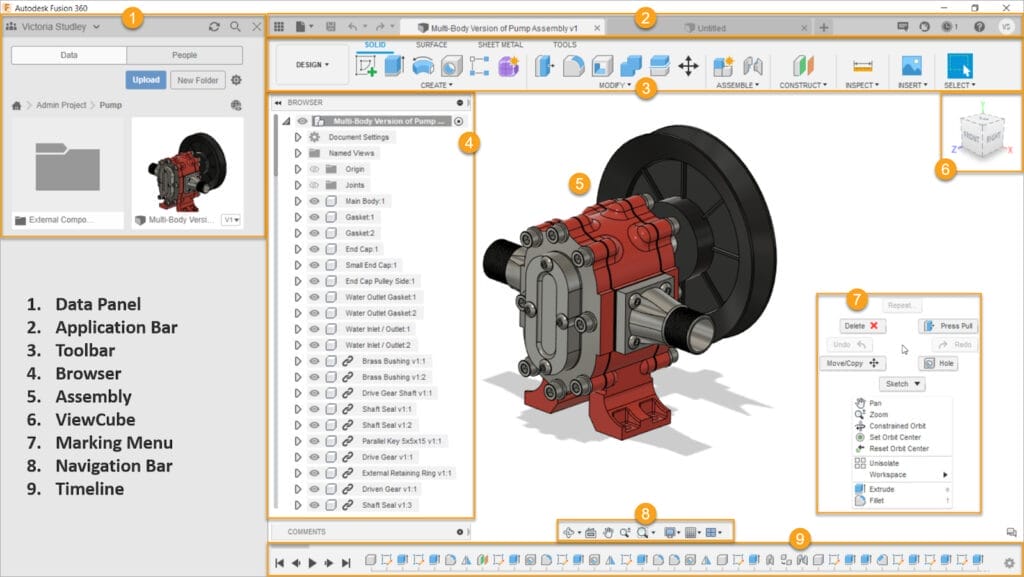

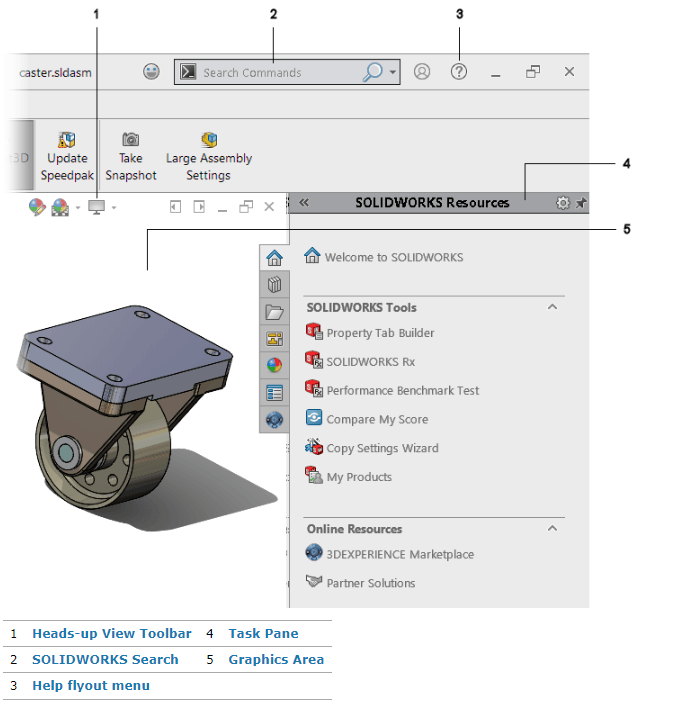

Both user interfaces allow you to change between tool sets. In Autodesk Fusion they are called Workspaces and Tabs. In SolidWorks they are called Toolbars. Both allow customization to some extent so commonly used tools are more accessible. Both include a hierarchical feature tree. Autodesk Fusion calls it the Browser and SolidWorks calls it the Feature Manager. Similarly, when you start using a tool, a separate box appears with the properties and inputs for that tool. Both allow for custom shortcut key combinations to be created for commonly used features. We won’t go on to list all the similarities in the user interfaces, but rather let’s take a closer look at what makes each unique.

Autodesk Fusion has a feature tree similar to SolidWorks, but it also includes a Timeline. This is a chronological history of how the design was created and can be edited at any point. This separates the features and the history, keeping the features more organized and making it easier to find what you’re looking for in a complex design. SolidWorks keeps a feature history, but it does it by appending new features to the end of the Feature Manager.

SolidWorks utilizes a unique feature called the shortcut bar. By default, this appears wherever your cursor is when you press the “S” key. It puts context specific (meaning they are different based on whether you’re working on a sketch, part, assembly or drawing) shortcuts right where you’re already pointing to save time. It’s also customizable so you can tailor it to your workflow.

Autodesk Fusion vs. SolidWorks: Price

Exact pricing is difficult to compare because these two applications are sold in different ways. Both can be purchased using a subscription-type model, where you pay a regular fee and get access to the latest versions of the software as it’s released. Both also currently offer a feature-limited, entry-level version for a significantly reduced cost.

Autodesk Fusion is a little more straightforward, in that you can visit their website and see the current pricing (sometimes they offer pretty generous discounts). You can also see the available extensions, what they provide and what they cost. The entry-level of Autodesk Fusion (for Personal Use) is completely free, with some limitations on features, number of designs you can have active at a time and the amount of income you can generate before needing to purchase the full version. The details of the limitations tend to change frequently, so we aren’t going to cover that here, but we recommend exploring your options to see if one of their lower cost options will work for you.

SolidWorks is a little harder. You can’t just visit the SolidWorks website, see your options and purchase a license. Okay, you can see your options, just not what they cost. Instead you’ll have to contact their sales department or one of their third party Value-Added Resellers (VARs) to discuss licensing. That is unless you’re looking at their license option for makers. Similar to Autodesk Fusion for Personal Use, SolidWorks for Makers is a feature-limited version at a significantly reduced cost. It isn’t free like Fusion’s option, but it is at least inexpensive enough to be a reasonable option for hobbyists. The full version of SolidWorks, even their most basic license, is likely much too expensive to justify unless you’re using it to generate income.

Summary: Both offer an entry-level option with some limitations compared to their more feature-complete versions. Autodesk Fusion for Personal Use is free, while SolidWorks for Makers is around $99/year or $9.99/month. If you need to remove the limitations, Autodesk Fusion can be had for around $545/year or $70/month, with any specific extensions an additional cost on top of that. SolidWorks pricing depends on which license you purchase and how you purchase it, but it tends to start around $4-5k/year for the most basic package and go up from there. SolidWorks has included a set of tools in its SolidWorks for Makers package to compete closely with Autodesk Fusion offering.

Note that these were the approximate prices at the time this article was written.

Autodesk Fusion vs. SolidWorks: Features

We saved the feature comparison for last as it’s one of the biggest differentiators between these two (next to price). As we mentioned before, both SolidWorks and Autodesk Fusion include all the standard mechanical design features you’d expect in a parametric 3D CAD software. Sketches (both 2D and 3D), extrudes, revolves, lofts, sweeps, holes, fillets, chamfers, reference geometry, mirror features, even sculpting depending on the versions, you get the idea. What really shows off the differences between these two, however, are the features each has that the other lacks. There’s no way we could cover them all, so we’ll hit some of the highlights.

Autodesk Fusion

- CAM Tools – Autodesk Fusion includes an amazing set of CAM (Computer Aided Manufacturing) tools. Before Autodesk Fusion, this was something you had to spend a lot of extra money to get. Now, other CAD systems (like SolidWorks) are including CAM tools to be competitive. If you’re running your own CNC machines, Autodesk Fusion should be high on your list for CAD software. You can get a limited set of CAM tools with SolidWorks, and you can pay for additional CAM tools, but the value Autodesk Fusion offers is tough to beat.

- Cloud Based – Autodesk Fusion makes it easy to collaborate, share designs and work from different locations (home and office maybe).

- Free/Cost – Yes, we’ve already discussed price, but the fact that Autodesk Fusion offers so much capability in their free version makes it a stand out feature. There are limitations to the free version, but they tend to be much less restrictive in practice than other CAD software. Even when you step up to the full version, the cost is still relatively low compared to SolidWorks.

- Seamless Upgrade – When you transition between the free version of Autodesk Fusion for Personal Use and the full paid version, the transition is seamless. All the files are the same. Designs created in the free version can be opened in a paid version, no issues. SolidWorks, at least at the time of this writing, does not necessarily allow this. Native files created in SolidWorks for Makers can’t be opened in standard SolidWorks. There are some workarounds for this, like exporting as a generic format or possibly contacting SolidWorks, but it isn’t a seamless process like it is with Autodesk Fusion.

SolidWorks

- Weldments – Rollcages, tube structures, 8020 frames, even 2×4 construction can all be quickly and easily designed using the weldments feature in SolidWorks. Weldments is a massive time saver for designing frameworks using standard (or custom) profile materials compared to doing it any other way (traditionally using sweeps). Download existing profiles or make your own. If you design structures like those and you’re not familiar with weldments, it’s definitely worth a look. Autodesk Fusion has a piping tool, but it doesn’t offer all the useful features of Solidworks Weldments. Coped ends, weld cut lists and custom profiles are just a few of the benefits you get with this tool.

- Part Libraries – Speaking of fasteners, SolidWorks includes libraries of common fasteners. Rather than trying to open an individual file, you can drag and drop common parts from an easy to navigate library. It also allows you to create your own custom libraries or import libraries of parts from vendors. 8020 for example provides their entire catalog of parts as a downloadable library.

- Macros – SolidWorks includes the ability to write or record (or download from the web) custom macros. These are extremely powerful and can be used to automate almost anything you can think of. Hide any solid bodies smaller than a specific size. Find all parts in an assembly with 6061 aluminum as the assigned material and change it to 5052 aluminum. Writing your own macros is definitely a power-user feature, but the web is full of resources where other users share macros they’ve written. Some users even offer their macro writing as a service you can pay for.

Which Software Is Better For Your Project?

Almost any project can be done with any tool, it’s just a question of finding a tool that makes the job easier. For hobbyists and startup businesses, Autodesk Fusion is hard to beat with all it offers either free or for a very small cost. If your business is CAD heavy and you expect it to grow, consider whether you’ll outgrow Autodesk Fusion in the long run in which case it may make sense to invest in SolidWorks. It should be noted that SolidWorks includes a lot more features than Autodesk Fusion. It’s been around longer and is significantly more expensive for the full license. So you can get ten times the features, but you’re also paying ten times the price. Do you need those additional features? That’s for you to decide.

The good news is that it’s relatively easy to try them both and decide which one you prefer.

Preparing Your Design For Laser Cutting

We understand how both beginners and advanced users can struggle to find the right CAD software for their projects. A lot of us here at SendCutSend are CAD users ourselves. There’s a good chance you decided to read this particular article because you need to have some parts laser cut. If you’ve got an urgent need and haven’t decided which CAD software you want to use, check out our Parts Builder. It’s a simple tool we’ve put together to give our customers the ability to easily get laser cut parts made without needing to generate their own CAD files.

If you have decided on which CAD program to use, but aren’t quite sure how to export your design to get it cut by SendCutSend, we’ve put together a few tutorials on our blog that should be able to walk you through the process.