If you want to save money on your project, keep in mind that our pricing is based on a number of factors, including material, material thickness, material weight, quantity, shape (geometry), and the overall design. Follow these tips to get the lowest prices on your laser cut parts:

- Reduce the number of holes or “pierces”

- Eliminate duplicate lines and unnecessary geometry

- Keep your design no larger than the maximum instant quote size for the material

- Use thinner materials

- Adjust quantity for discounts and free shipping

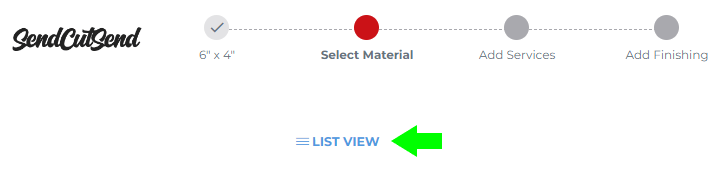

Sometimes a design can benefit from a few small tweaks that will lower the price and save you money. You can always compare material options after uploading your file to our website to find the best option for your budget.

Read more about how to get better pricing and join our mailing list for access to exclusive promotions!