Need to know how to join lines on a common axis to create one bend in Fusion? Autodesk’s support forum has excellent guidance here: How to join sketch lines to single line in Fusion 360

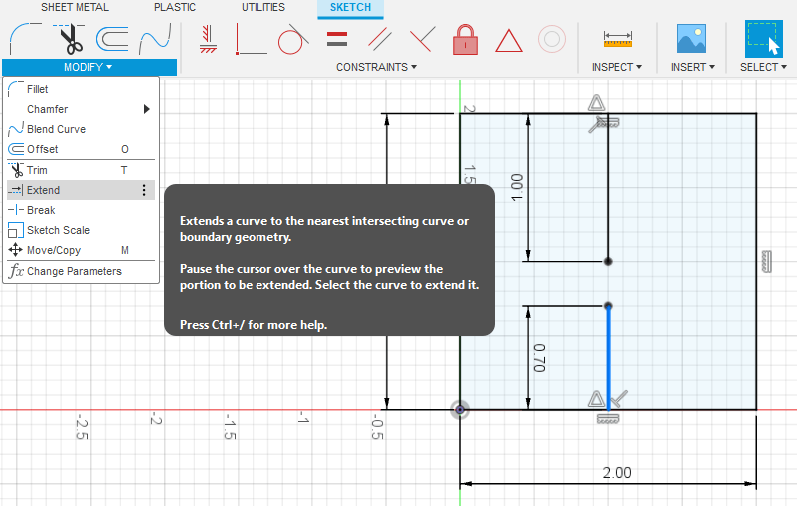

To join collinear sketch lines in Fusion, from the Sketch tab you click MODIFY and choose Extend. This will extend a line to the nearest intersecting boundary geometry.

Bending Considerations

When adding bends to any design, use SendCutSend’s Bending Calculator to confirm that the flat design’s dimensions will result in the bent dimensions you require. Your flat pattern will always need to be a little shorter than the finished part since the bending process stretches the material. We have more information about this here: Guide to Calculating Bend Allowance and Bend Deduction

Adding Bends in Fusion 360

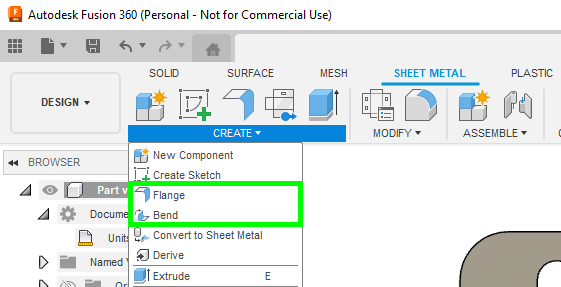

The most commonly used methods for adding bends in Fusion 360 are the Bend and Flange sheet metal tools. You can use either depending on your preferred workflow. We’ve briefly summarized each tool’s functionality below. Click here for a detailed comparison between the Bend and Flange tools.

Bend Tool

Draw your sketch including bend lines using the correct flat pattern dimensions, convert to sheet metal, apply a sheet metal rule, then use the Bend tool to add bends where your bend lines are. The Bend tool will apply the sheet metal rule to the 3D part. We have step-by-step instructions for using the Bend tool here.

Flange Tool

Sketch the base of your part, convert to sheet metal, apply a sheet metal rule, then add flanges at the desired formed dimensions. When you export your flat pattern from Fusion, it will be at the correct (slightly shorter) dimensions to compensate for bend deduction. We have step-by-step instructions for using the Flange tool here.

Export a 2D DXF from the Flat Pattern

Once your bent part design is ready, follow our guide: How To Export a DXF from Fusion 360 – SendCutSend

For more Fusion 360 advice, see our Fusion tutorials!

In Summary:

To join lines on a common axis and create one bend, see Autodesk’s support guidance here: How to join sketch lines to single line in Fusion 360. When adding bends to any design use SendCutSend’s Bending Calculator to confirm that the flat design’s dimensions will result in the bent dimensions you require.