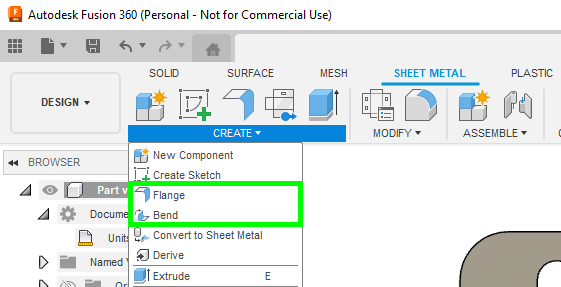

When you’re working on a bent design in Autodesk Fusion, it seems there wouldn’t be a difference between the Flange and Bend sheet metal tools.

Believe it or not, there is a significant difference between the two! The tool of choice depends on your preferred workflow and design goals.

Please note, both tools require that you create sheet metal rules using the bend specifications provided for each material and thickness in SendCutSend’s Bending Calculator page. We have instructions for creating sheet metal rules in Fusion here.

Using the Bend tool in Fusion

This tool applies the sheet metal rule you choose to a flat part when you add a bend. Therefore the 3D design will be slightly longer to reflect the stretching that will occur when your part is bent. When the design is exported to a 2D file, the DXF will be the same dimensions as your initial sketch. We have detailed step-by-step instructions for using the Bend tool here.

Using the Flange tool in Fusion

After you’ve drawn the base of your part and converted it to sheet metal, the Flange tool allows you to add flanges to the base.

With the Flange tool, you dictate how long you want the finished flange and base to be in the 3D space. When the design is exported, the flat pattern will be slightly shorter to compensate for stretching of the material per the sheet metal rule you applied. Your finished bent part should be the same dimensions as the 3D part you designed. We have detailed step-by-step instructions for using the Flange tool here.

Always use the Bending Calculator

For either tool, use SendCutSend’s Bending Calculator to confirm that the flat design’s dimensions will result in the bent dimensions required. Your flat pattern will always need to be a little shorter than the desired finished part since the bending process stretches the material. We have more information about this here: Guide to Calculating Bend Allowance and Bend Deduction

When your design is ready, export a 2D DXF by following the steps in our guide here: How To Export a DXF from Autodesk Fusion – SendCutSend

In Summary:

The tool of choice depends on your preferred workflow and design goals. Take a look at our Flange tool and Bend tool use guides to learn how each one works. Then, determine the best option for your project. Always use the Bending Calculator to check that your flat pattern will result in the formed dimensions you need.