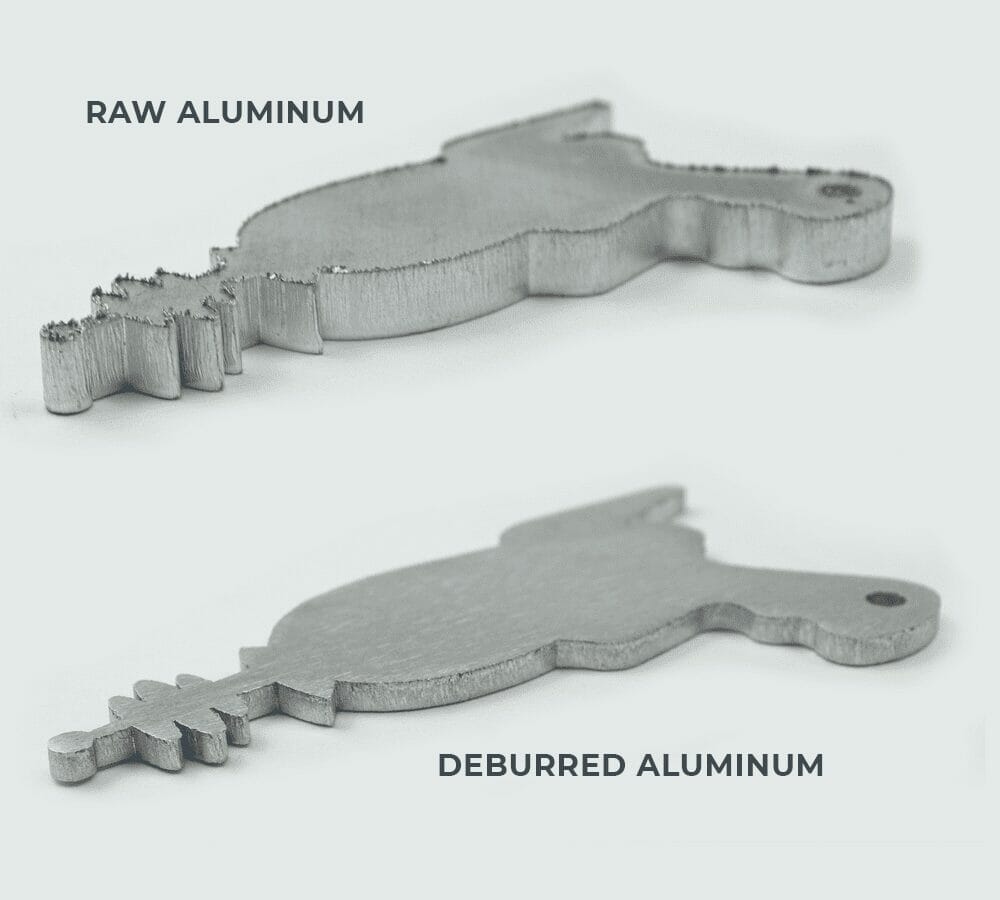

Parts with our linear deburring service will have sharp edges. The surface will be smooth and “cleaned up” from laser cutting, but there will be no edge softening.

Take a look at the video below to learn more about our linear deburring process!

Our tumbling services can provide partial edge softening. However ceramic tumbling is only available for smaller parts in qualifying materials and thicknesses. Tumbling typically adds 2-3 business days to order lead times depending on part quantity.

Learn more about our ceramic tumbling services!

In Summary:

Parts with our linear deburring service will have sharp edges. The surface will be smooth and “cleaned up” from laser cutting, but there will be no edge softening.

Ceramic tumbling can be added before checkout to qualifying parts to provide edge softening, but there will be a service charge. Learn about our tumbling service requirements.