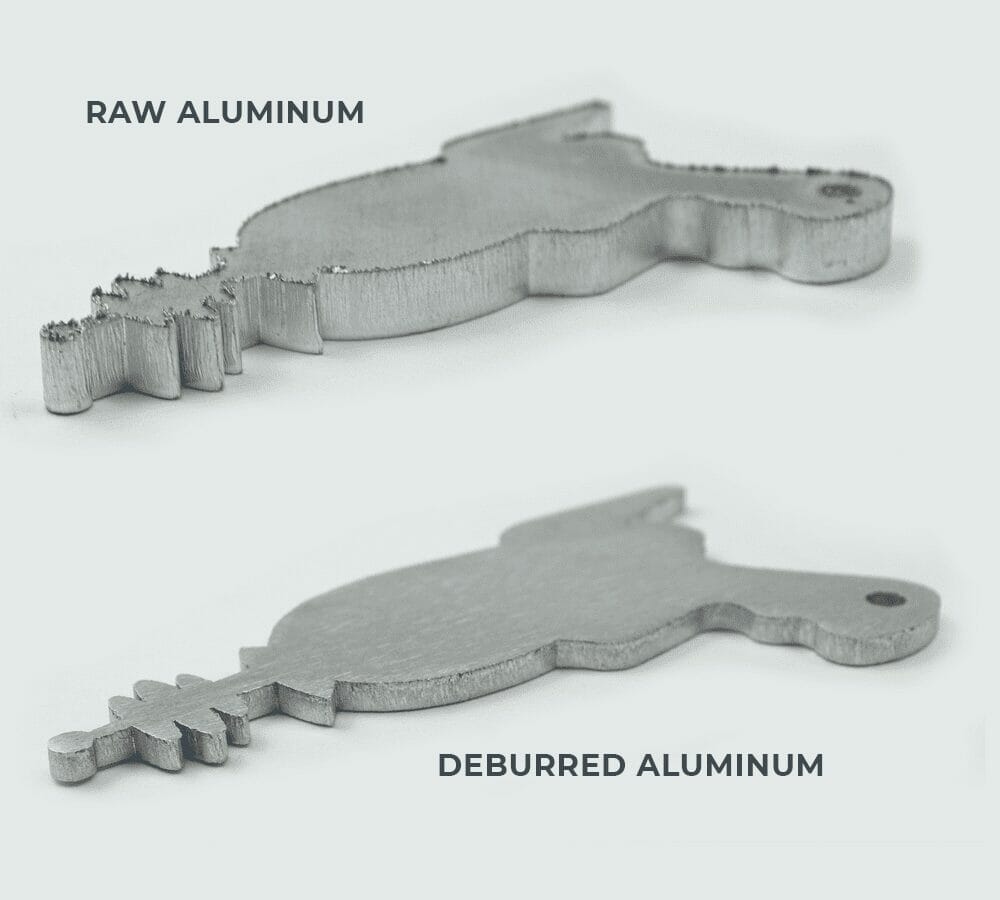

There will inevitably be scratches left on the surface of your part after the machining process, especially on the bottom side that contacts the laser bed. Thick aluminum (>.250″) may have a slight burr on the bottom edge. If you want to minimize the effect the scratches will have on the final look of your part, select linear deburring or tumbling before checkout if your parts are eligible.

Linear deburring or tumbling can help minimize scratches

Our linear deburring and tumbling services have minimum and maximum part size and material thickness limitations. Confirm which material thicknesses and part sizes are eligible in our handy charts: Part Size Limits for Processing

Linear deburring and ceramic tumbling are not finishing processes and will leave some imperfections on the surface and edges of your parts. However, they will remove major imperfections like dross and burr, and many of the scratches from the machining process.

Linear deburring provides a nice brushed look, and the edges of your part may be slightly rounded off. Keep in mind that our linear deburring is not a cosmetic process. If you need a perfect grain like a 4B brushed finish (think stainless steel refrigerator), plan to perform additional finishing when the parts get to you.

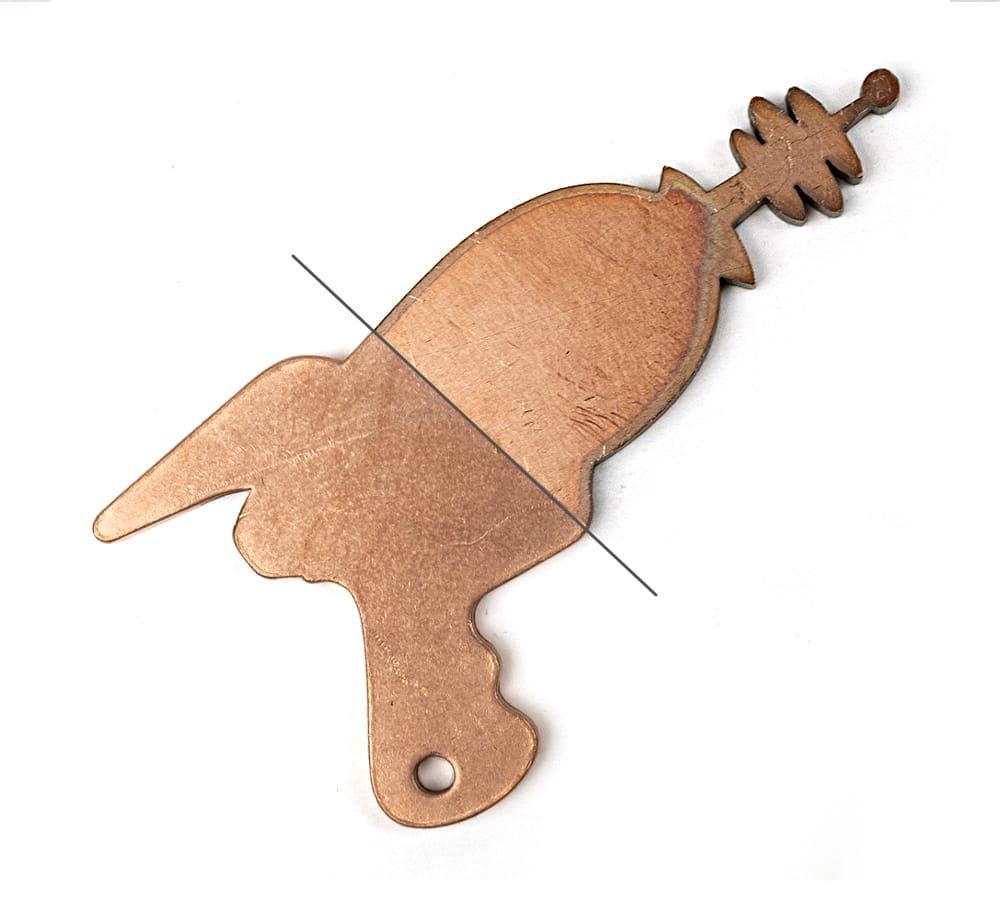

Our tumbling service will give your parts a slightly “antiqued” look, provide edge breaking, and clean up most scratches. Tumbling is not a cosmetic process or suited for delicate designs in thinner materials. Learn more on our tumbling guidelines page.

Consider powder coating to help cover scratches

Interested in a full finishing process that will protect your part from wear and tear and hide imperfections? Check out SendCutSend’s powder coating service!

Lean clean machine

Scratches are inevitable with laser cut sheet metal parts, but our cleanup and finishing services help deliver good looking parts to your door. Have more questions? See our surface finish FAQs before uploading your designs to our website and placing an order!