When you need corrosion resistance, strength, and weldability, turn to laser cut titanium grade 2 to get the job done. Titanium Grade 2 is titanium in its purest commercial form, bringing elegance and and durability to every project.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 56″

.040″ (1.02mm)

Our Grade 2 titanium is commercially pure, meaning that it is not an alloy. It’s non-magnetic, non-toxic, and non-allergenic, which has led to its increasing use in the medical field. Despite being as strong as steel, titanium is about 40 percent lighter, which, along with its resistance to erosion, makes it an essential structural metal for aerospace engineers.

Titanium is also formidable in its resistance to corrosion by both water and most chemicals. This resistance is achieved by forming a thin layer of titanium dioxide on its surface that is extremely difficult for these materials to penetrate. Ensuring that when you use it in your next project, corrosion will be the last thing on your mind.

Grade 2 titanium is often the superior choice when looking at usages that are more concerned with its corrosion resistance than the strength it offers. Able to be formed and welded with ease, titanium remains a critical part of the aerospace and chemical processing industries.

We like to mention that commercially pure titanium grades do not have the same strength as their alloyed cousins. This is, of course, true for most alloys, but don’t be fooled, Grade 2 titanium is still very strong. While categorized as only moderate in overall strength for this material, it’s important to remember that it’s still very much used in high-stress applications and can get your job done.

For more strength, look at our Grade 5.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

This material is available in one thickness option: .040″ (1.02mm).

SendCutSend cuts Grade 2 Titanium in a broad range of sizes and thicknesses. Instant quoting is available for parts as small as .25″ x .375″ and as large as 30″ x 44″. Larger parts, up to 30″ x 56″, can be ordered through a custom quote.

You can add the following services to your Grade 2 Titanium parts:

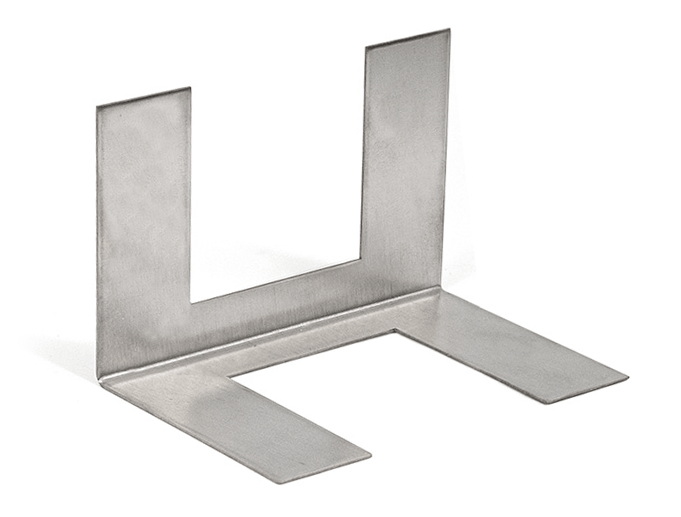

Bending