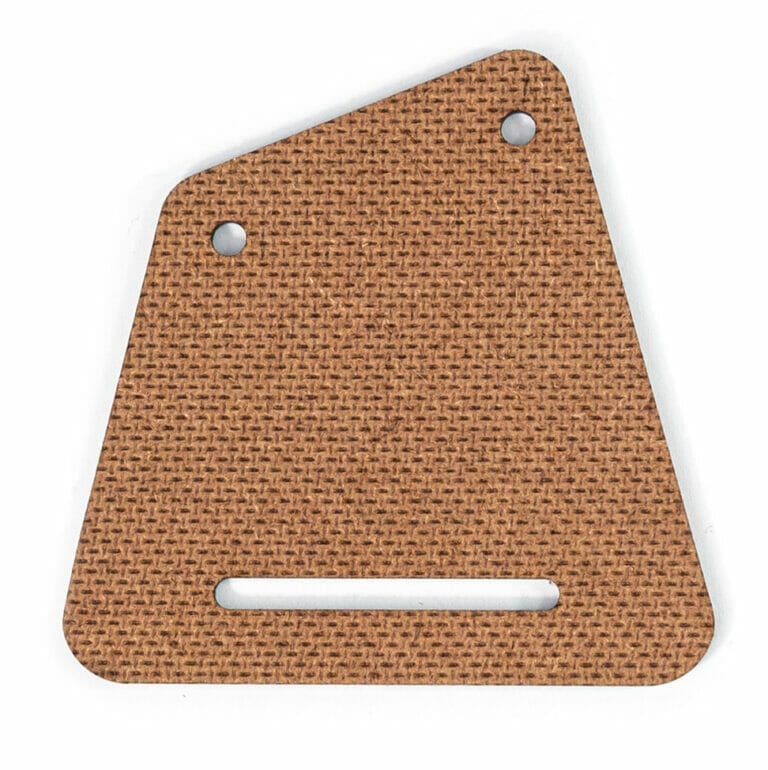

Prototyping with our laser cut hardboard will help ensure your product’s success before you ever place a full production run. Durable, workable, and affordable, laser cut hardboard will change the way you prototype and save you money simultaneously.

A: .25″ x .375″

B: 20″ x 26″

.125″ (3.18mm)

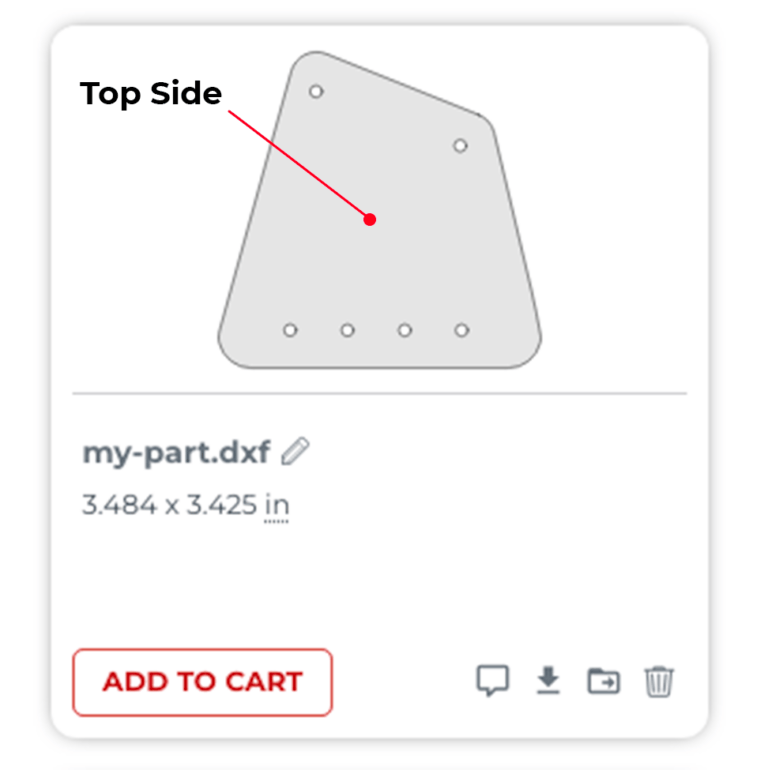

Please note (especially for mirroring parts), the finishes on the front and back may differ. The top side is smooth and the back will be textured. We will cut your file smooth side up.

The orientation of your part as shown in the part preview will be considered the top side.

Prototyping with our laser cut hardboard will help ensure your product’s success before you ever place a full production run. Durable, workable, and affordable, laser cut hardboard will change the way you prototype and save you money simultaneously.

Hardboard parts are limited only by your imagination. One of the best applications for laser cut hardboard is in prototyping. With its warping resistance and comparatively high strength, hardboard can be used to prototype any number of potential parts and products.

With 0.009” tolerance on our CO2 lasers, we’re able to cut your parts with high accuracy, getting your prototypes as close as possible to the “real thing.” We recommend placing a small order with several test parts, and thanks to the affordability of hardboard, you don’t have to worry about needing quantity discounts to come in under budget.

Once you’ve received the test parts and are pleased with the design, check out our other high quality materials and get a quote on your full production run!

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.