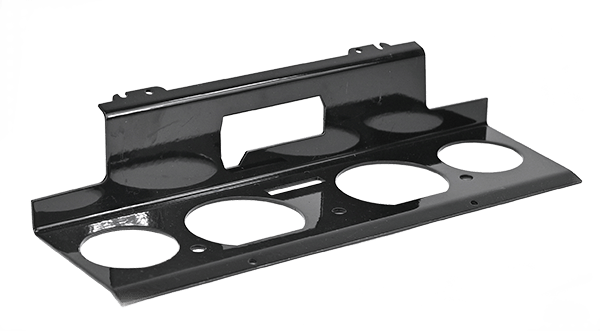

CNC metal bending is the most popular add-on service we offer here at SendCutSend. So much so that we’ve coined the hashtag #SendBENDSend. If you’re looking to turn your 2D project into a 3D part, then bending is where you start.

For this reason, we’re continually looking for ways to expand our bending capabilities adding more materials, more thicknesses, and the ability to bend larger parts.

Overall flat size can now be up to 44″ x 30″ and up to .250″ thick. See our material details for max bend lengths on specific materials.

SendCutSend Sheet Metal Bending Highlights

Here’s what you need to know about our online sheet metal bending services

- Bending services start from $19 with no minimum quantity, and as low as $1 per part in bulk

- Bending is specific to each metal and thickness

- We bend your laser cut parts to your specifications within one degree of accuracy or better

- We currently do not offer acute angles greater than 130°, or curl, bump, roll forming, coining, or hemming

Materials Available for Metal Bending

We currently bend eight different materials in a variety of thicknesses.

- 5052 Aluminum

- Brass

- 4130 Chromoly

- Copper

- G90 Steel

- Mild Steel

- 304 Stainless Steel

- 316 Stainless Steel

Our bend limits will vary depending on material and material thickness, so you want to be sure to check the material details that are outlined on each material page before uploading your design.

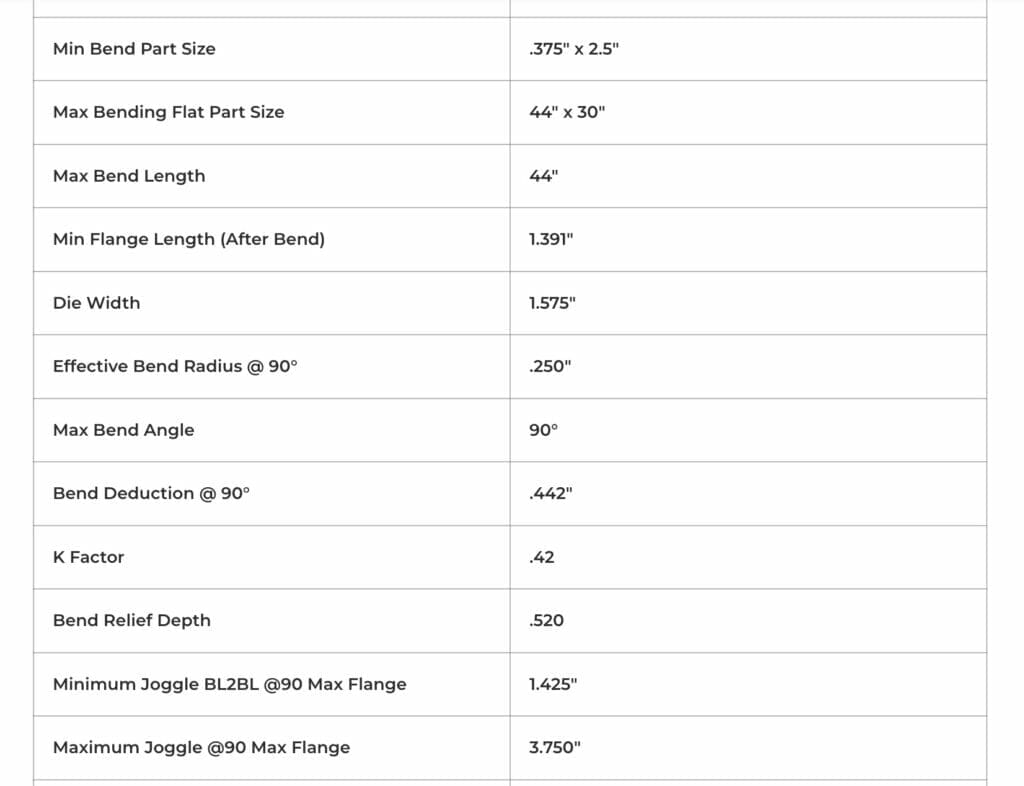

For example, here are the design considerations for bending 5052 aluminum at .040″:

Here are the design considerations for bending 5052 aluminum at .250″:

Helpful Resources for Metal Bending Parts with SendCutSend

We want to make it as efficient and easy as possible to get your parts bent with us. That’s why we’ve provided a variety of resources from design guidelines to CAD tutorials for your design.

Bending Laser Cut Parts with SendCutSend Video Guides

If you prefer to get your metal bending tips via video tutorial instead of text, check out our bending video tutorial series.

If you have any questions about SendCutSend’s sheet metal bending services, feel free to reach out to our support team.

And don’t forget to tag us on all your awesome bending projects #SendBendSend!