For sheet and plate parts, submit DXF, DWG, STEP/STP, EPS, or AI files with simple unthreaded full depth holes; we’ll resize them to match your selected tap size. For CNC machined billet parts, submit STEP/STP files with simple holes (no modeled threads) and note your tap sizes at the Add Services step. See our Tapping Guidelines for details.

1. Sheet and plate part file setup

We accept the following file types for tapping in sheet and plate parts: DXF, DWG, STEP, STP, EPS, and AI.

Key considerations for tapping services with sheet and plate parts:

- Holes: Must be ≤ 4.00″ in diameter and designed as simple circles (no threads).

- Automatic resizing: During checkout, you’ll choose your desired tap size. We’ll resize your holes automatically to match the correct drill size. Reference our Drill & Tap Size Chart for details.

- Cutting considerations: File must also meet our Cutting Design Guidelines for the chosen material.

- Clearance: Ensure tapped holes are the required distance from other features — check the Material Specifications for spacing rules.

- Orientation: Holes must be perpendicular to the sheet’s main surface; we don’t tap at angles.

- Hole depth: Holes in sheet and plate materials must be full-depth.

- Size limits: Confirm your overall flat part size meets our Tapping Processing Limits.

- Available tap sizes: These vary by material and thickness; check our processing limits to confirm.

2. CNC machined billet part file setup

For billet parts ordered through our CNC machining service, submit files in STEP or STP format.

Key considerations for tapping services with billet parts:

- Holes: Model holes as simple holes, not threaded geometry.

- Hole diameter: Model holes that you want tapped with a diameter that matches the major diameter of the thread for the tap size you need; we’ve listed the ideal hole diameter for each tap size in our CNC Machining Thread Chart.

- Hole depth: we can create partial depth (blind) holes in CNC machined billet parts and tap them.

- Thread depth: Should not exceed 3× the tap diameter (3XD). Example: a ¼-20 tap (0.25″ diameter) should not exceed 0.75″ depth.

- Hole placement: Keep hole centers at least 1.5× the tap diameter away from any edge or shoulder. (e.g., 0.375″ for a ¼-20).

- Thread sizes: Confirm available taps in our CNC Machining Thread Chart.

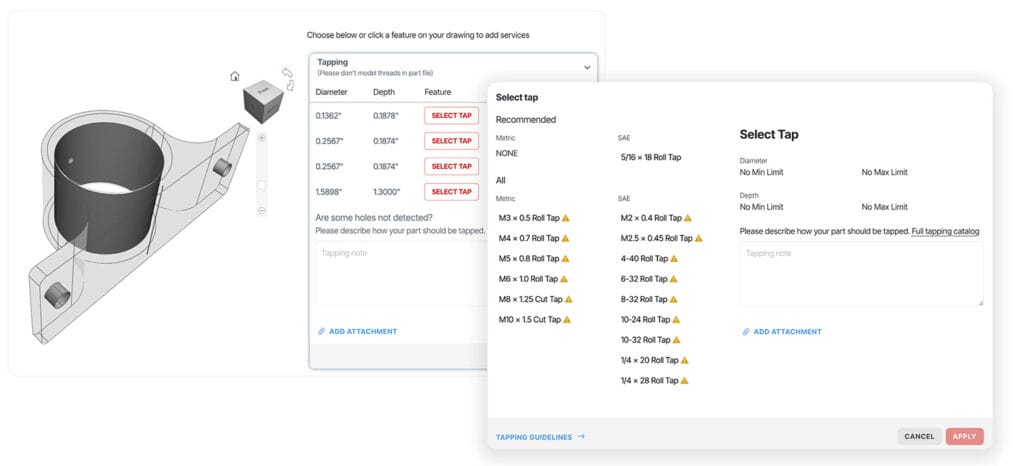

- Checkout notes: After uploading your STEP/STP file, specify tapping instructions at the Add Services step.

- Design guidelines: See our CNC Machining Guidelines for more on setup.

The bottom line

- Sheet/plate parts: Submit vector or 3D files, simple full depth holes ≤ 4.00″, we’ll resize automatically at checkout.

- CNC billet parts: Submit STEP/STP, design simple untapped holes (either blind or full depth), confirm sizes in our charts, and specify tapping at the Add Services step before checkout.

Important reminders

- Don’t model threads into your CAD files — just simple holes.

- Our hole sizes per tap are specific to our process. If you plan to tap holes yourself after receiving your parts, use the drill chart from your tap manufacturer instead.

- Our DFM team reviews every part before machining. If there’s a concern about tap placement or geometry, we’ll contact you before production.

For all details, see our Tapping Guidelines or reach out to our US-based Support team anytime!