Bend radius depends on more than just thickness — tooling, material tensile strength, and die width all play a role. Some thinner materials may even have a larger bend radius than thicker ones.

If you want to know why the bend radius specification for a material doesn’t always correlate with the material thickness in a linear fashion, read on!

Our bend radius specs

- Each material and thickness has a set effective inside bend radius

- Specs are listed in our Material Catalog and Bending Calculator

- Custom bend radii are not available — design with the material’s specific bend radius in mind.

Why thickness ≠ radius

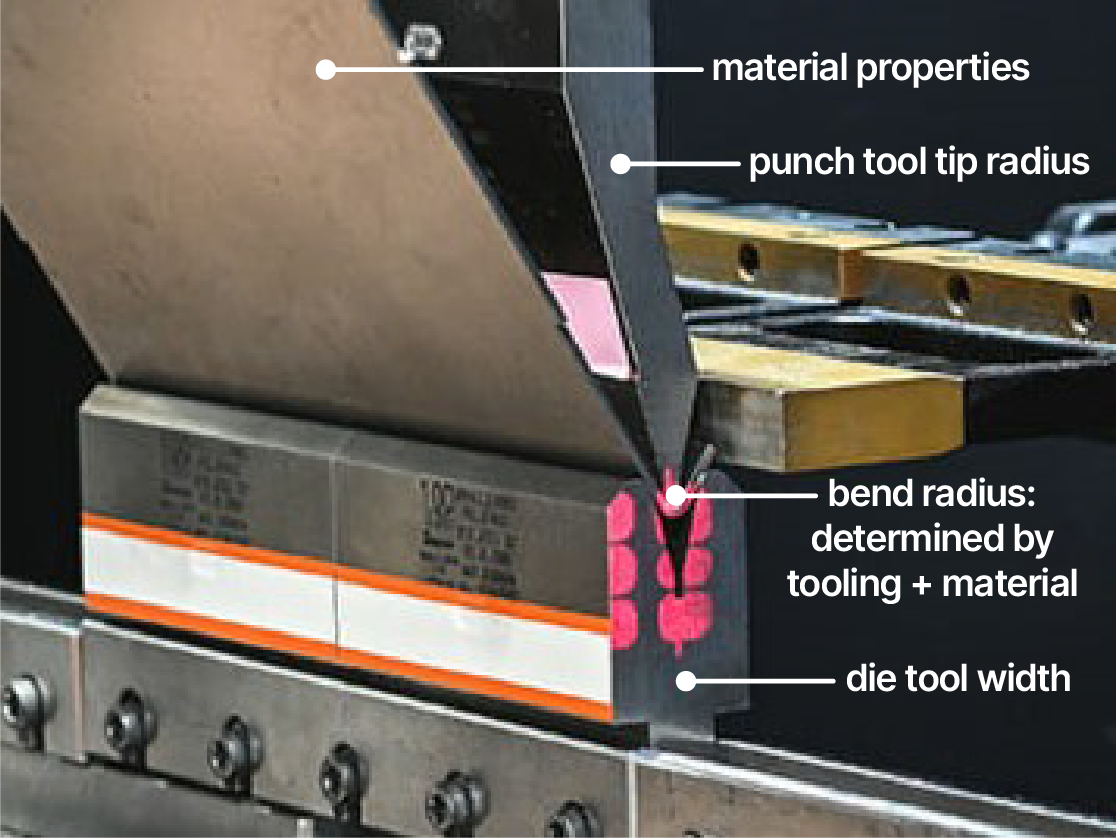

Bend radius is influenced by:

- Punch tip radius

- Die width

- Material tensile strength

- Stronger materials (like stainless steel) resist bending more, which can lead to a larger effective radius.

- A thinner sheet of high-tensile material might bend with a larger radius than a thicker sheet of softer material.

Design tips:

- 2D CAD: Use our Bending Calculator for accurate flat pattern dimensions

- 3D CAD: Create sheet metal rules with our exact specs for bend radius and K factor

- Download our free Autodesk Fusion 360 or SolidWorks gauge tables for fast setup

Bottom line:

Don’t guess — check our specs for your material before you design. They’re tuned for our press brake tooling and will get you the formed dimensions you expect.

For assistance, reach out to our Support team anytime with your bending questions!