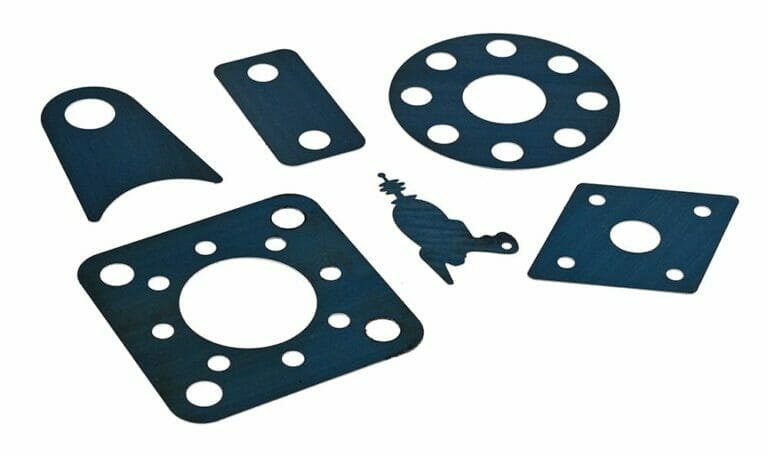

Relying on its superior tensile and yield strengths, 1075 spring steel is positioned as the essential material for spring, coil, and shim manufacturing. Our laser cut 1075 Blue Tempered Spring Steel (also known as Scaleless Blue Tempered Steel) is perfect for spring applications or where stiffness is required with minimal thickness.

Instant quote

A: .25″ x .375″

B: 13″ x 44″

Custom quote

C: 13″ x 56″

.015″ (.381mm)

1075 blue tempered spring steel is a type of high-carbon steel renowned for its exceptional resilience, strength, and durability. The “blue temper” refers to the process of heating the steel to a specific temperature and then cooling it rapidly to achieve optimal hardness and toughness. This steel is characterized by its ability to resist deformation and return to its original shape after being subjected to stress, making it ideal for applications requiring reliable spring properties.

1075 Blue Temper Spring Steel is a versatile steel that isn’t just for springs, clamps, and coils. It’s often used in blade-making as well. It’s able to hold its edge well and is receptive to sharpening. It also has much better workability and toughness than something with a higher carbon count (like 1095).

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.