With SendCutSend’s material catalog being as diverse and comprehensive as it is, a common question is what material would be best for a certain application. Because of this, we are working on writing articles to help decide which material is best for your custom laser cut parts.

In this article, we are going to be focusing on the Wood and Board section of our catalog. Since most use cases would only be using one group of materials, we are currently publishing articles for each group such as the Plastics and Composites sections individually.

Article Contents:

- Overview of All Woods & Boards We Offer

- Cost Comparison

- Considering the Manufacturing Process

- Wrap Up

Material Breakdown:

Baltic Birch Plywood

Pros:

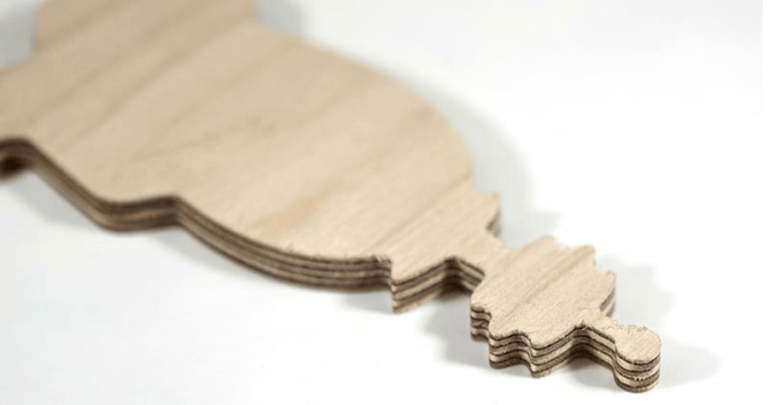

Plywood is a popular choice with our laser cut services for the same reason it’s so popular elsewhere: it’s inexpensive, workable, attractive, and extremely versatile. Since it is the only wood/board in our catalog formed using layers rather than chips, fibers, or particles, it has many characteristics that distinguish it from our other offerings. The material holds screws well, is easy to modify without affecting its integrity, and aesthetically still possesses a traditional wood grain making it a good option for signage and as an exterior material.

Cons:

The properties that make it Baltic Birch Plywood unique are also the ones that make it comparatively expensive to the other materials in this lineup. It is, however, still more affordable than almost any material outside of this category. At this time we only offer this plywood in 0.354” and 0.472” thicknesses. Because of this, it must be cut on a CNC router which is a little more complex from a design standpoint (more on that below). While this thickness does ensure that the material is strong enough for almost any application it’s typically used for and makes it resistant to bowing, it does make it too large, too heavy, or too expensive for some applications and scales. It entirely depends on your criteria and constraints.

Typical Uses:

- Furniture

- Stereo speakers

- Store Fixtures

- Cabinets

- Door parts

- Toys

- Musical instruments

- Indoor signage

Chipboard

Pros:

Chipboard is one of the most affordable materials in our catalog making it fantastic for basic prototyping and templating for non-structural applications. The material is durable and yet 100% recyclable making it fantastic for fast, disposable prototyping in a manner that doesn’t affect the environment. Due to its thinness, the material is bendable by hand and easy to work with. If you have a complex part that you want to check dimensions, alignment, or fitment for, this is a fantastic material to do the job.

Cons:

What makes chipboard affordable and workable is also a major limiting factor in its use cases. At the time of writing, we only offer this material in 0.03” thickness (about 7 sheets of printer paper thick) meaning that it is rarely used as a structural piece of any kind.

Typical Uses:

- Crafting

- Prototyping

- Book covers

- Business cards

Hardboard

Pros:

Hardboard is most comparable to MDF but unique in its own right due to its unusual warping and weather resistance. This material is optimal for prototyping due to its high strength and versatility in comparison to other materials in this price range. Additionally, Hardboard and MDF are the only two kinds of wood we currently offer in ⅛” thickness making it easily transferable to common metal thicknesses and applications. The material is also relatively light in comparison to Plywood or MDF (about half the weight) making it a good prototyping material for weight-dependent applications that may be transitioned to a lightweight composite or plastic beyond the initial development stage.

Cons:

With the properties hardboard possesses, there are a few drawbacks and limitations to what can be done with it. Much like the other materials in this lineup, the only issues are with its aesthetics and the variety of thicknesses it’s offered in. Since Hardboard is a fiber-based material, it does not have wood grain and has a relatively uniform appearance. In regards to thicknesses, this material is currently only offered in ⅛” thickness which is great for many applications but not for all.

Typical Uses:

- Wall paneling

- Flooring protection

- Lightweight furniture

- Prototyping (especially load-bearing)

MDF

Pros:

MDF is often seen as inferior to plywood, but in reality, its performance is often indistinguishable in the majority of applications. The material is strong, workable, and rigid due to its particle-based construction. The primary advantage MDF has over plywood is its affordability as it tends to cost considerably less. Otherwise, it’s safe to treat this material as a slightly less rigid version of plywood.

Cons:

The reason MDF cost less than plywood has to do with some of its fundamental properties caused by its construction. While it is an easy material to coat and paint, it does melt in water and warps easily without coating making it a poor material for external environments where it could be exposed to the elements. This is caused by MDF’s fiber-based construction (why it’s often referred to as fiber board) which uses an adhesive that is not resistive to the elements to hold the particles together.

Additionally, we advise against using this material for aesthetic applications at the time of writing due to variations in its appearance caused by lingering pandemic supply shortages. These shortages do not affect the material’s integrity like we once experienced with plywood shortages, but can cause varying color tones.

This material also weighs slightly more than plywood making it the heaviest material in our woods/board lineup. Lastly, like most of our other materials, we use our CNC routing service above ¼” thickness due to time and efficiency.

Typical Uses:

- Large runs of production furniture

- Door parts

- Instruments

- Cabinets

- Vapor repulsion

- Fire resistance

- Soundproofing

- speakers

Cost Analysis

There are three major things to keep in mind when trying to determine the cost of your part: part size, material thickness, and raw material pricing. A 0.030” thick chipboard is clearly going to be weaker than 0.354” thick sheet of plywood. Because of that, both the pricing and functionality of that part is going to be completely different with those two materials. This idea is also important to keep in mind when comparing wood to other materials for laser cutting as an equivalently strong metal or composite material will likely be a much thinner variety.

And lastly, the material pricing. At this time, global supply chain interruptions are still greatly affecting lumber prices causing our pricing for these materials to fluctuate considerably as well. While we expect the cost of each material relative to one another to remain similar, the prices themselves may change so be sure to get instant pricing for the most up-to-date pricing.

Manufacturing Process

As mentioned for some of the materials above, certain thicknesses and varieties of materials require our CNC routing service rather than online laser cutting. For other material groups in our catalog, this can vary by material but for woods and boards it strictly has to do with thickness. If you plan on using a material in this line up above ¼”, we will cut it on our CNC router.

While this will not fundamentally change the design of your parts, you may have to make slight modifications to your part so that it will be cut correctly. Regardless of the cutting service your part will use, it must still meet the guidelines for the respective process.

The CNC guidelines, however, have just a few more requirements. All holes/interior cutouts must be at least 0.125” to accommodate the CNC router’s tooling, and the minimum part size for CNC routing is 1” x 2”. Additionally, you’ll want to make sure that all bridging / webbing is at least 1:1 to the material thickness. While this may be a dealbreaker for extremely small parts made at a large thickness, for the vast majority of applications it ends up not being a big deal just requiring a little more time.

If you find yourself in a scenario where your part can’t be manufactured on a CNC and needs to be that thick, we recommend considering layering multiple of the same part in a thinner material to create the thickness. While it may not have 100% of the strength as your intended part, it can often be more affordable and easier to manufacture.

Be sure to check the material info page for the wood/board you choose. Scroll down to the Material Details to find the Design Considerations for the stock thickness you need. Check that the minimum hole, minimum bridge, and minimum hole-to-edge sizes are met throughout your design.

Wrap Up

Just like other industries, we most often use common materials like woods and boards for common applications. With this article, we hope you now have a better understanding of what those common applications are and what some of the not-so-common ones would be to help you pick the best material for your budget and application.

SendCutSend provides low cost laser cutting services across the US. If you’re looking for laser cutting near me consider our online laser cutting services which provide fast turn-arounds and parts to your door in just a few days. If you have any questions feel free to explore our instant pricing tool and contact us.