If you’ve noticed our new part preview tools and want to know more, you’ve come to the right place! These tools allow you to directly measure parts in your SendCutSend account, avoid feature deformation with bent parts, and more.

Accessing the part preview tools

You can access the preview tools for any part in your account by clicking the part image.

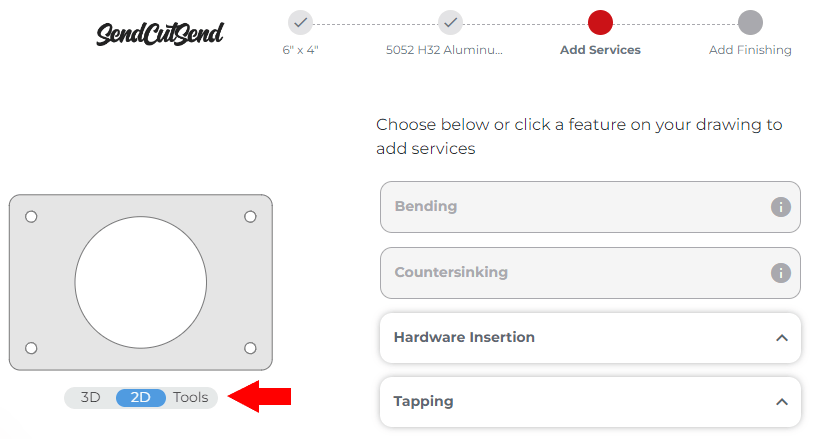

You can also access the part preview from the instant pricing and configuration dialogue once a material has been selected.

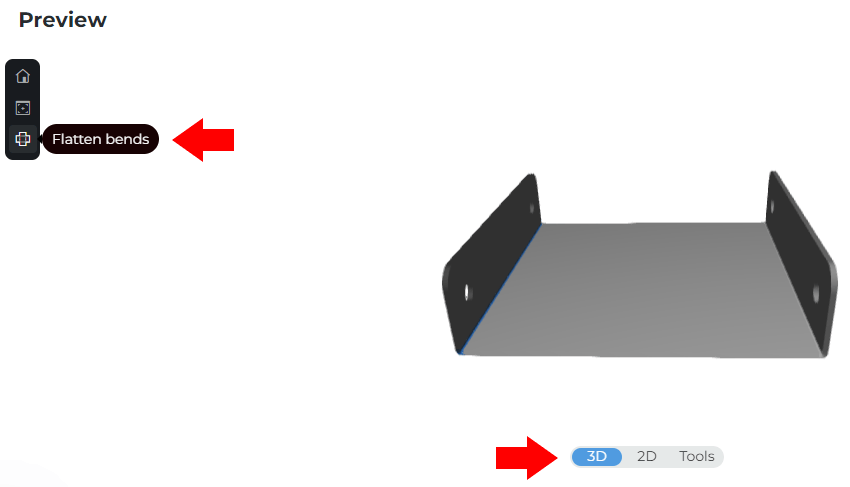

Below the 2D part image, you’ll see the option for a 3D view, 2D view, or Tools.

Preview tool options

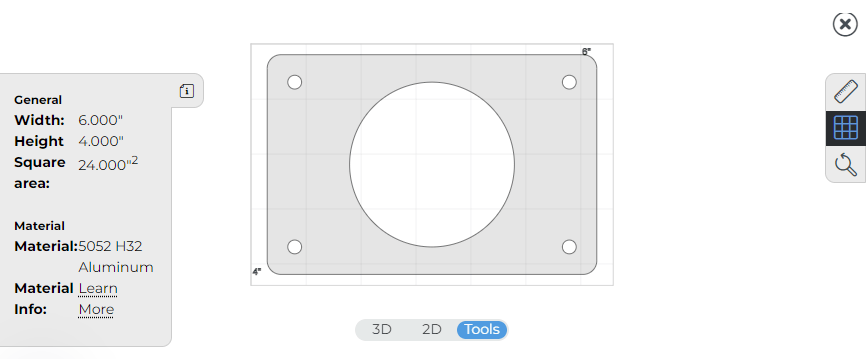

Once you toggle the Tools view, you’ll see options on the right for

- a measuring tool,

- a grid, and

- a preview reset button.

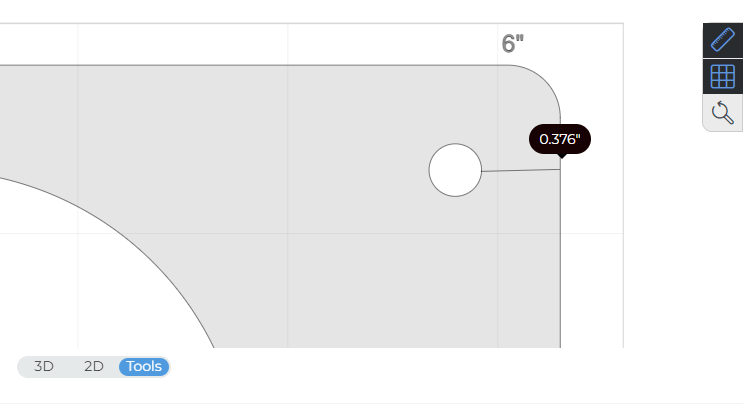

If you hover over any circular hole, the diameter will be shown.

On the left, you can click the tab to Show details about the part, including

- width,

- height,

- square area, and

- material info if a material is configured for the part.

Click Learn More to find material details including specifications and properties.

Moving parts in the preview space

You can zoom in on specific areas using your scroll wheel or by moving two fingers up or down on a track pad.

If you need to move the part around the 2D preview, you can left-click on the part and drag it.

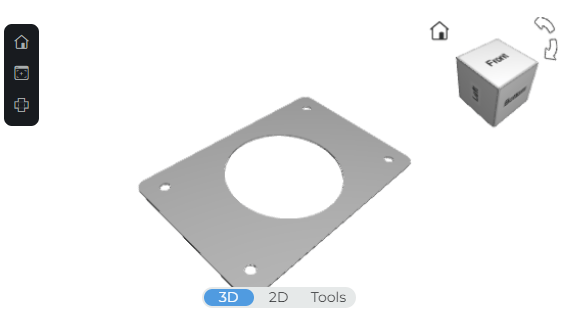

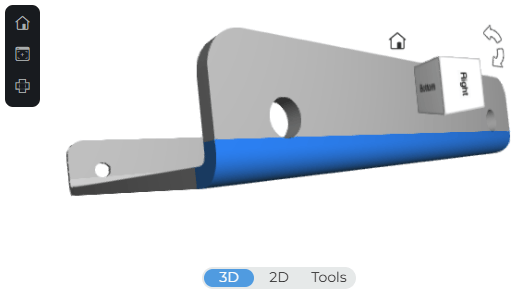

When in the 3D view, you’ll need to right-click to move a part since left-clicking rotates 3D parts. You can also use the 3D position cube to rotate a part, or return it to the isometric view by clicking the home icon.

Measuring parts with the preview tools

To use the measuring tool, toggle it on. Then click once on the first point to start measuring and click a second time to get a measurement.

Please note, it’s not possible to zoom in while the measuring tool is active.

Bend preview tools

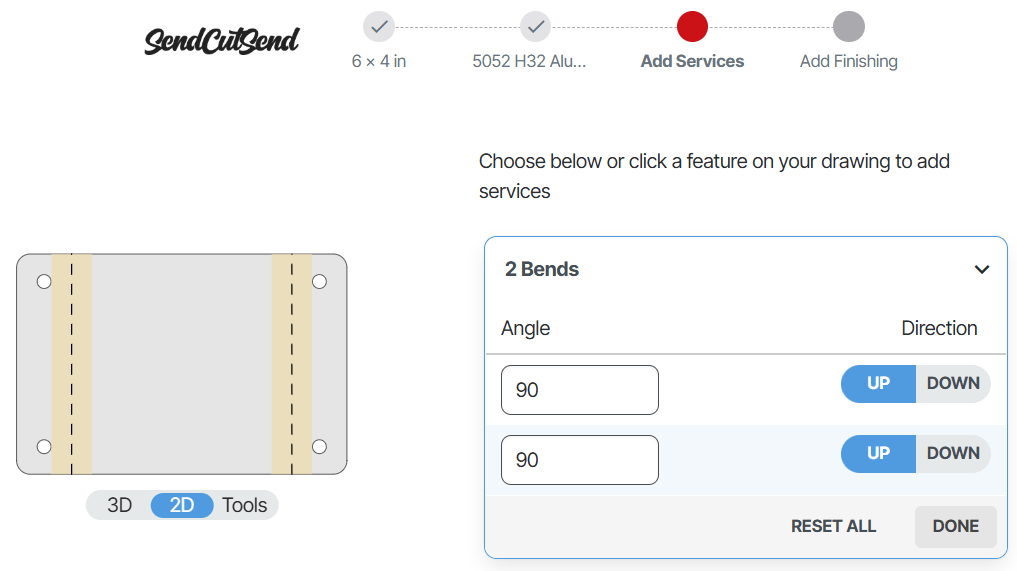

If you apply bending services to your part, additional tools become available.

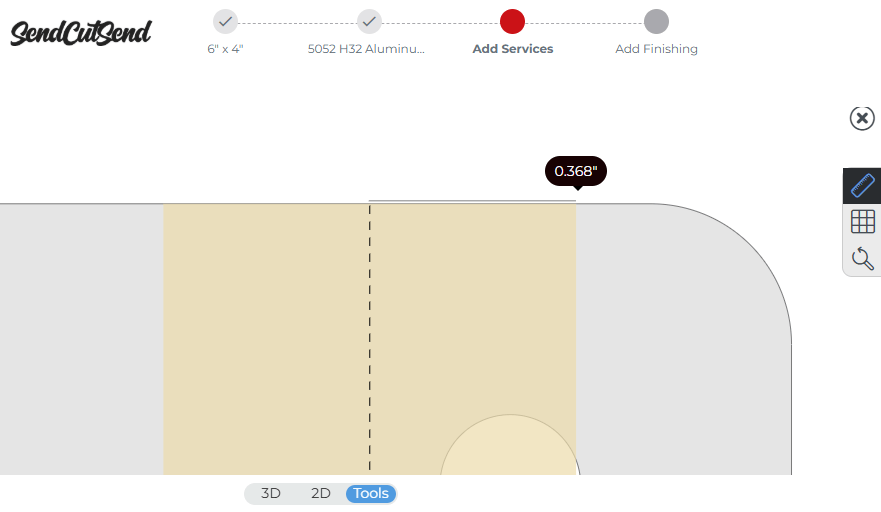

While viewing Bending services, select a bend line to see the bend caution areas highlighted in yellow.

The yellow highlighted areas or “caution areas” show where deformation will occur if cut features are too close to the bend line. The caution area distance is the minimum flat flange length required on each side of the bend line to form the part.

If you view the part in 3D, you can highlight the bend area if desired. It will have a smaller appearance but does show where the most severe distortion would occur if features are close to the bend line.

For detailed guidance on avoiding deformation with bent parts, see our Bending Deformation Guidelines.

If desired, you can flatten or unfold your bent part in the 3D view by clicking Flatten bends in the 3D preview options on the top left.

If you have any questions about previewing your parts, our Support team is happy to help!