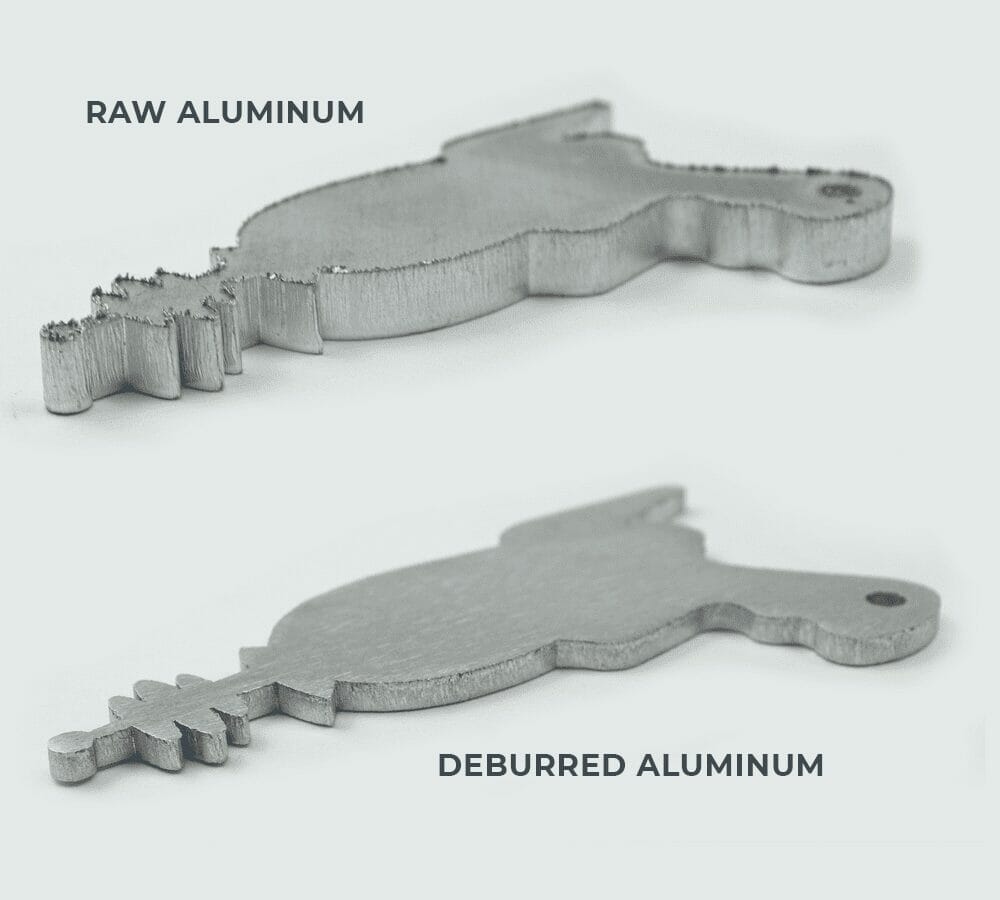

SendCutSend’s state-of-the-art laser and waterjet cutting prevent major burr and dross buildup on your part, but both imperfections are still unavoidable parts of the manufacturing process. Read through our information pages for your chosen material to see pictures of what buildup looks like in different thicknesses.

While you can’t directly prevent burr and dross, it’s important to follow our design guidelines completely. This is because small geometry on thicker materials can contribute to buildup on your part.

We also offer linear deburring and tumbling for an extra fee to remove the worst imperfections and scratches. If you’re at all concerned about buildup, consider selecting one of those services during the ordering process if your parts are eligible.

SendCutSend’s state-of-the-art laser and waterjet cutting prevent major buildup on your part! However these imperfections are still unavoidable aspects of the manufacturing process. Read through our information pages for your chosen material to see pictures of what dross/burr looks like in different thicknesses. Consider adding linear deburring or ceramic tumbling services to help clean up your parts from the laser cutting process.