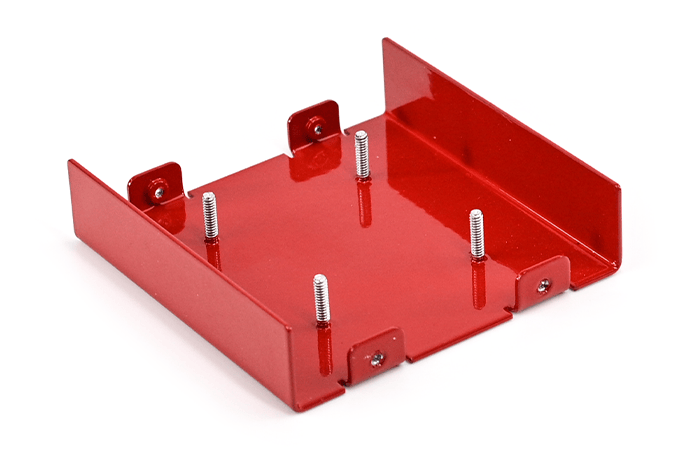

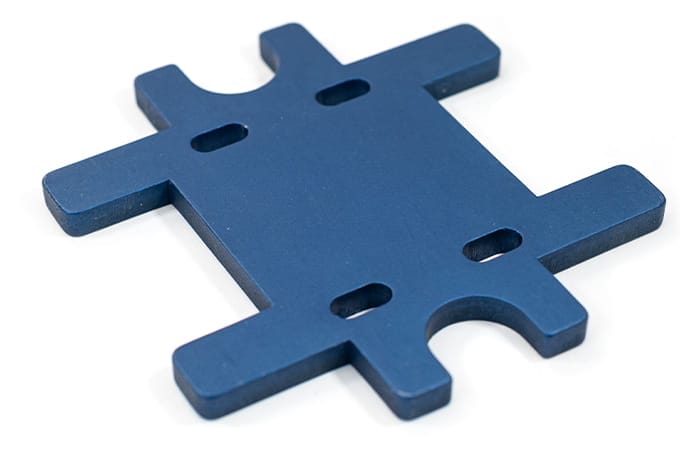

How to prevent corner flanges from colliding?

If your design has perpendicular flanges that meet in a corner, like a box, you’ll want to ensure there’s enough clearance so the flanges don’t collide and prevent the operations from being completed. Learn how to build clearance into your designs!