If you uploaded a 2D vector file (DXF, DWG, EPS, or Adobe Illustrator format) to our website and found that bend location lines in your file are not being recognized by our quoting system, we can help! Troubleshoot your file with these tips.

For help with 3D files, please see Why won’t my STEP or STP file upload?

STEP and STP files do not require bend lines since you can model the part with bent flanges in 3D, save the STEP or STP format file, and upload it directly to our website. Ensure your design meets our 3D File Guidelines before uploading.

The line type may not be set correctly for your design program

Ensure the bend lines are set up correctly for successfully exported files. These are the bend line types we recommend for popular CAD programs:

| Software | 2D Format | Bend line |

| Adobe Illustrator | .ai | Solid, separate color from cut lines |

| AutoCAD | .dxf | Dashed line – not Hidden |

| CorelDraw | .eps | Solid, separate color from cut lines |

| Fusion | .dxf | Solid line (default)* |

| Inkscape | .eps | Solid, separate color from cut lines |

| SolidWorks | .dxf | Dashed line (default) – not Hidden** |

| QCAD | .dxf | Dashed line |

*Follow our Autodesk Fusion bend file export guide here: Exporting to DXF from Autodesk Fusion

**If you’re using SolidWorks 2021 or older, reference this article for bend export. If you’re using SolidWorks 2022 or newer, please reference this article.

Your 2D file did not export correctly

We have many CAD tutorials and file setup FAQs to help with exporting 2D vector files successfully in the formats we accept. Give those a try if your bend lines are the right type, but aren’t being recognized!

Your bend lines are on a layer that is hidden

Make sure that your file includes only the cut geometry and bend location lines. Your cut geometry should always be a solid/continuous line type, while the bend lines may need to be dashed depending on your design software. All geometry should be visible in your file.

If you’d like to review your flat DXF or DWG file before uploading it to our website, check out Preflighting Bent Sheet Metal Parts in QCAD.

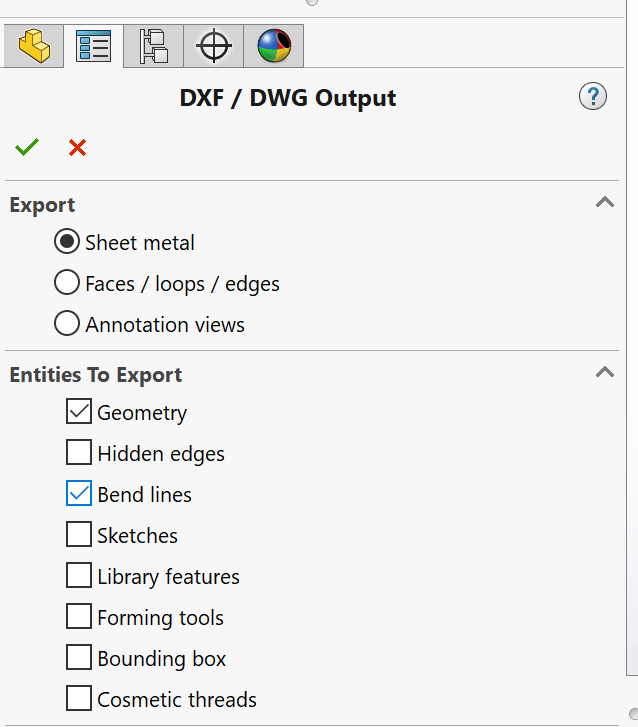

In SolidWorks, the Bend lines box is not checked for DXF / DWG output

If you’re exporting from SolidWorks, make sure the Bend lines box is ticked in the DXF / DWG Output window.

The importance of bend lines

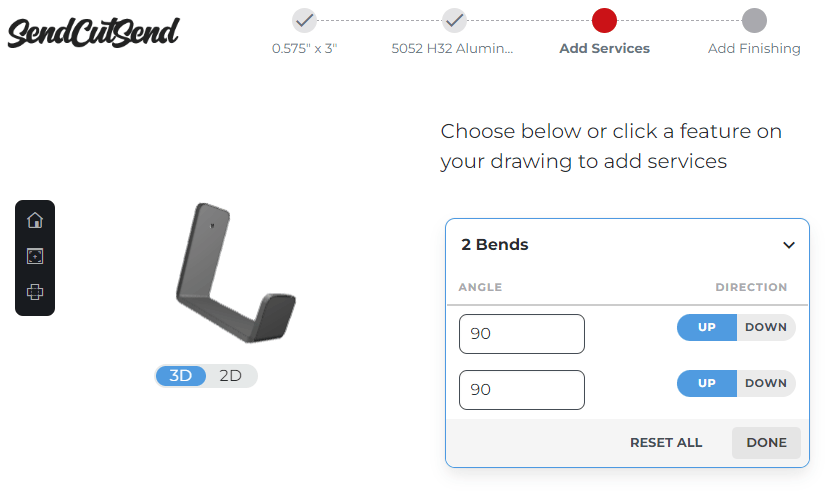

Bend lines should mark the center of each bend required for your part. We need bend lines to be present in 2D design files so we’ll know exactly where to perform the operations. This is why it is not possible to add or configure bends unless the bend lines are recognized by our quoting system.

If your file is set up correctly, you should be able to add bending operations and specify the degree and direction of each bend.

If these tips do not help reveal your bend lines, please contact our Support team and attach your design file. Our team will be happy to help!