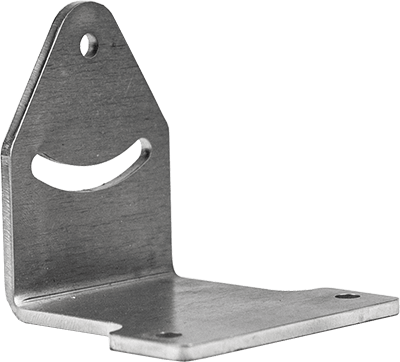

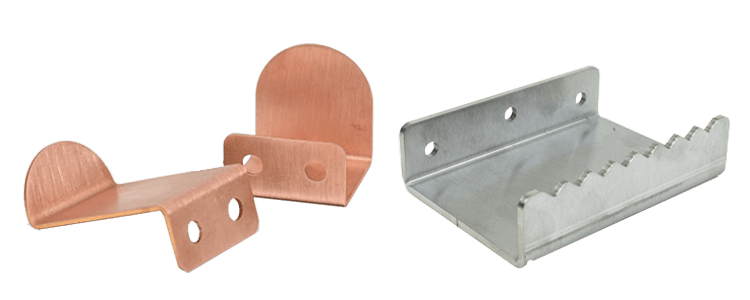

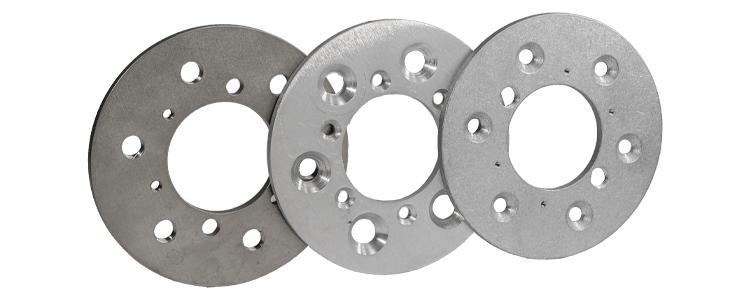

Can you provide Ra or surface roughness specifications?

We don’t provide Ra or surface roughness specifications at this time. To provide the best value, material suppliers can change and mill finishes may have varying surface roughness. If one of our finishing services is not added for sheet metal parts, your parts will ship with the mill finish.