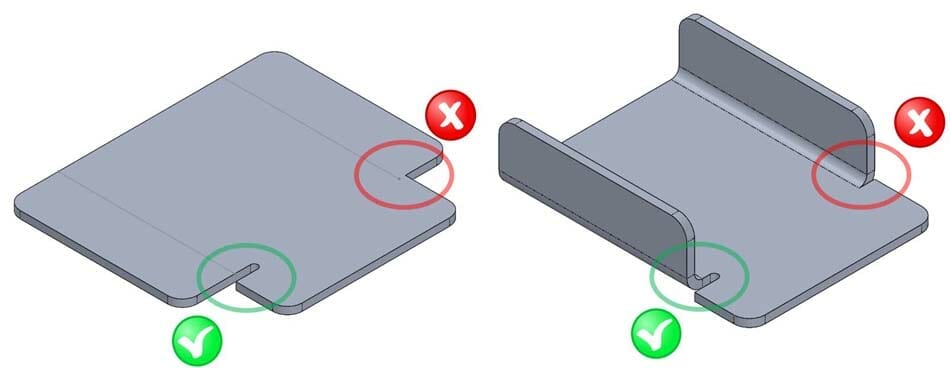

Bend relief notches reduce stress and tearing where bends meet corners. For sheet metal, we recommend reliefs — especially on thicker materials. For polycarbonate, reliefs are required and must meet strict shape and depth specs.

Bend reliefs are small cut features placed where a bend meets a corner. They let the material flex without tearing, bulging, or deforming, and prevent the bend’s flange from interfering with the base material.

1. Why bend reliefs matter

Without reliefs, the inner bend radius takes the full forming stress. This can:

- Cause corner bulging

- Tear the material at the bend

- Distort adjacent features

By adding reliefs:

- Stress is distributed evenly

- Flanges form cleanly

- Corners keep their intended geometry

2. Minimum bend relief size

For most materials, relief notches should be:

- Width: ≥ 50% of material thickness

- Depth: Bend radius + material thickness +

0.020"

📄 See our Bending Deformation Guidelines for more on relief placement and its effects.

3. Polycarbonate bend relief requirements

Polycarbonate is prone to cracking if reliefs are missing or undersized.

- Reliefs must be rectangular

- Must meet the minimum bend relief depth for your thickness

- Specs are listed on our Polycarbonate Material Page

If your polycarbonate design doesn’t meet relief specs, it’s likely to fail during forming.

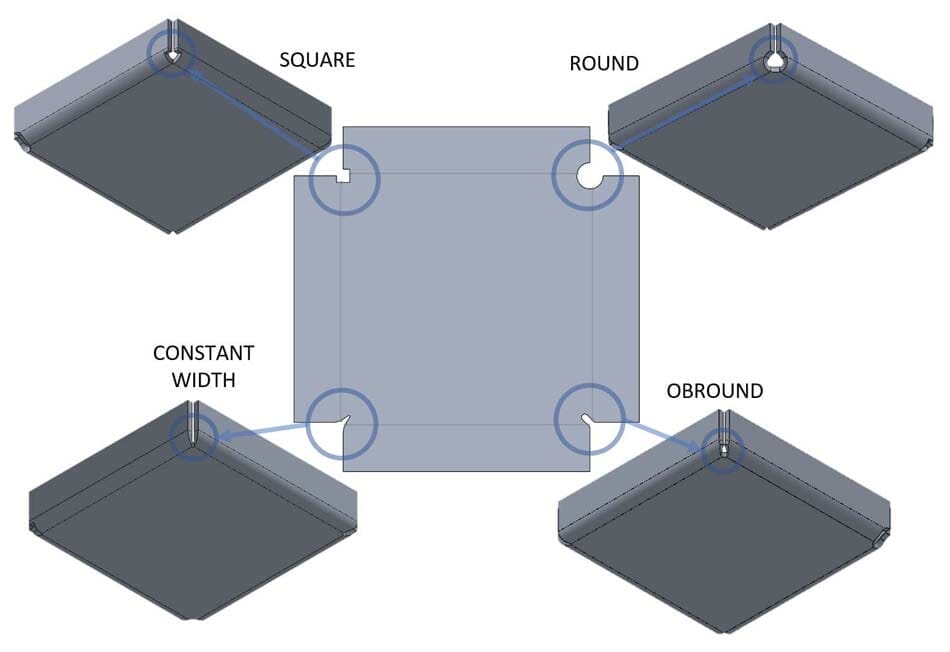

4. Sheet metal bend relief recommendations

- Reliefs are optional for thinner metals, but we strongly recommend them for materials 0.187” and thicker

- You can use any relief shape you prefer (rectangular, circular, narrow notch)

- Even with thin materials, reliefs improve aesthetics by reducing corner distortion

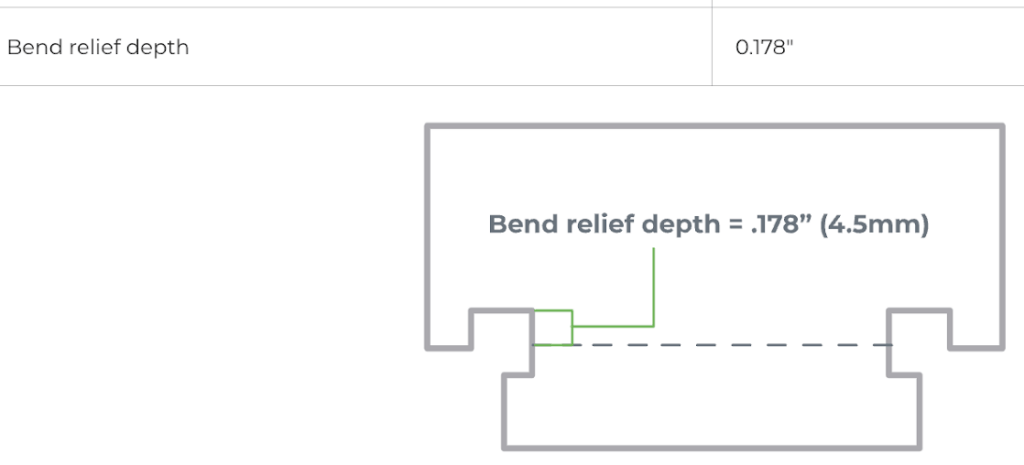

5. How to measure bend relief depth

On your flat pattern:

- Locate the bend line (center of the bend)

- Measure from that line to the bottom of the relief notch

- The distance should meet or exceed the minimum depth spec for your material

6. Alternative to adding a relief

If possible, move the bend location so it no longer needs a relief. This can be a quick fix that maintains part strength while avoiding extra geometry.

Feeling relieved?

While there is some flexibility with our sheet metal bend relief requirements, it’s critical that polycarbonate parts meet relief specifications. Be sure to review our complete bending guidelines before uploading your part file to our website for an instant quote. If you have questions just ask our Support team!