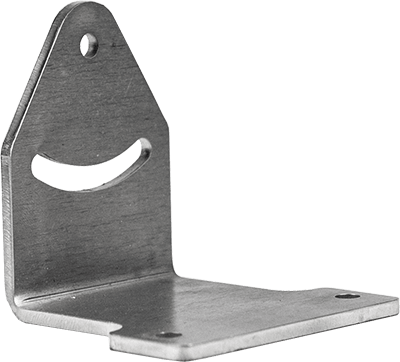

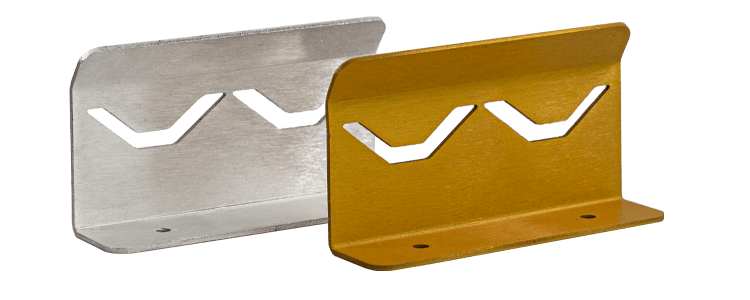

How do I keep perpendicular corner flanges from colliding in my design?

To keep perpendicular flanges from clashing in a corner, use our Min Corner Relief Distance from Bend Line spec (pictured below). If the clearance between bend lines meets or exceeds that value for your chosen material thickness, you’re in the clear.