Here’s what to expect when you get parts powder coated! From lead time, combination with other services, and how to get the best results, we’ve got you covered!

Powder coated parts have a longer lead time

Powder coating will add a 7-10 days of additional lead time to your order.

Need both powder coated and non-powder coated parts? We strongly recommend ordering finished and unfinished parts separately so we can ship your non-powder coated parts as soon as they’re done being machined.

What to expect if combining other services on powder coating

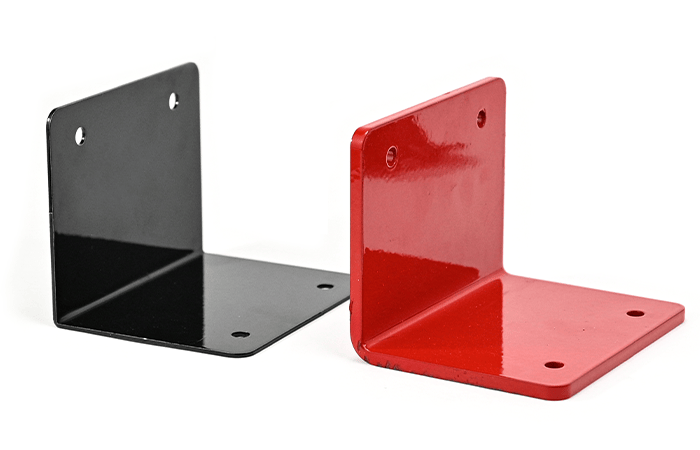

Bending/forming + powder coating

If your powder coated parts are bent/formed, be aware that the die witness marks from the press brake will be visible through the coating.

Tapping + powder coating

At this time, we cannot plug tapped holes before the parts are powder coated, so you will have to chase the holes with a tap to clear the threads once you receive the parts.

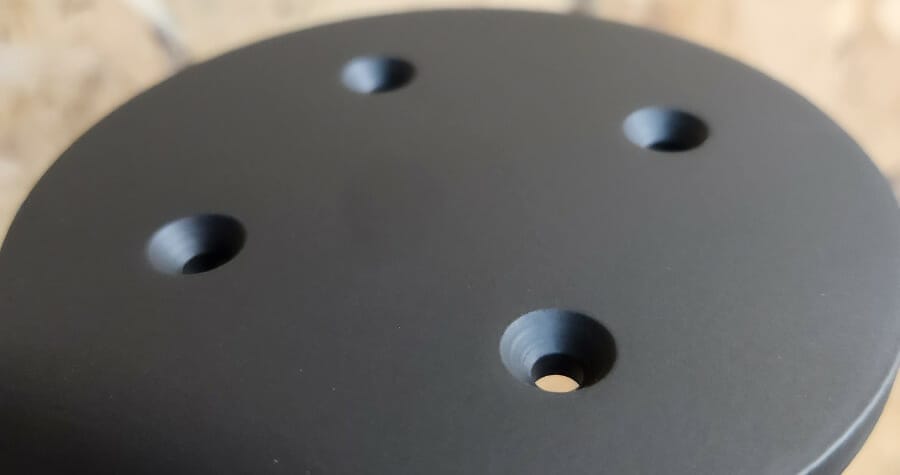

Countersinking + powder coating

Powder coating will add .002”-.005” (.051mm-0.13mm) per side. We’ll adjust the hole size to account for this, but keep in mind that the fit may be tight on countersunk holes with powder coating.

No single line etching or no-kerf geometry

We cannot provide single line etching or no-kerf single line cuts on any of your powder coated parts as the powder will completely cover or fill them.

Mind the gap

When designing features to be laser cut or bent on your part prior to powder coating, we recommend keeping a gap at least 0.040″ wide between them. This will help prevent powder buildup from creating an unwanted bridge during the powder coating process.

Micro tabs on laser cut parts

We also do not offer tab removal so micro joints/tabs will be visible through the powder coat. These are typically 0.015-0.030″ in width depending on the material and roughly .010″ in height.

In Summary:

Powder coated parts will require an additional 7-10 days to process.

For bent parts, the die line witness marks from the press brake will show through the powder finish.

With tapped parts, you’ll need to chase the holes to remove powder buildup when parts get to you.

For countersunk parts, the fit on countersunk holes may be tight.

Single line etching and no-kerf single line through-cut geometry is not available.

Avoid clogging and buildup of powder by keeping features at least 0.040″ wide.

Micro tabs from the laser cutting process will be visible through the powder coat finish.

If you still have questions about expectations and standards for powder coated orders, read our guidelines for more information! Upload your part file to our website for instant pricing when your design is ready.