You can find tolerances for bending in the specifications on each material info page in our Material Catalog. Bending tolerances refer to the amount of deviation that is possible from the part as designed. This affects finished part dimensions and bend angles.

Please note: bend radius and K factor are set per material thickness and cannot be changed upon request. Use our Bending Calculator or set up sheet metal rules using our material bending specifications to ensure your parts turn out as expected.

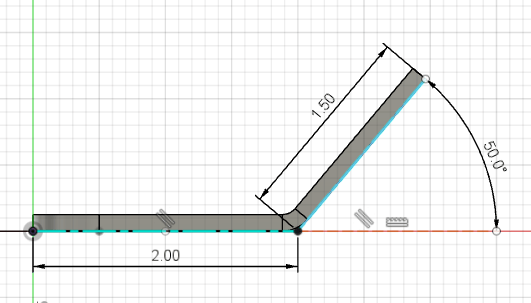

Bend angle tolerances

Bend angle tolerances indicate the number of degrees that a part’s flange may vary from the design’s definition.

For example, if a material has an angle tolerance of +/- 1 degree, then a flange defined at 90 degrees may have an angle of 91 or 89 degrees when the part gets to you. Learn how to find bend angle tolerance specifications for each material.

Keep in mind that metal and plastic material have different tolerance considerations. Learn more about bending plastic.

Sheet metal bend angle tolerances

- Sheet metal parts will have a +/- 1-degree bend angle tolerance on bends up to 24” long

- Sheet metal parts will have a +/- 2-degree bend angle tolerance on bends longer than 24”

Sheet plastic bend angle tolerances

- Polycarbonate parts will have a +/- 5-degree bend angle tolerance on bends up to 24” long

- Polycarbonate parts will have a +/- 7-degree bend angle tolerance on bends longer than 24”

You can also confirm polycarbonate bend tolerances on the polycarbonate material page.

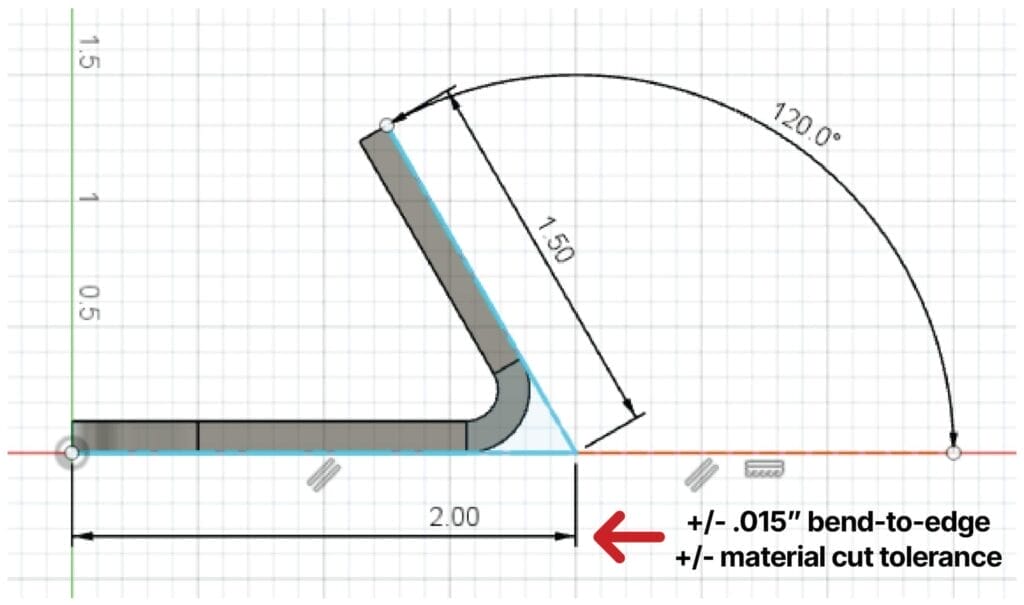

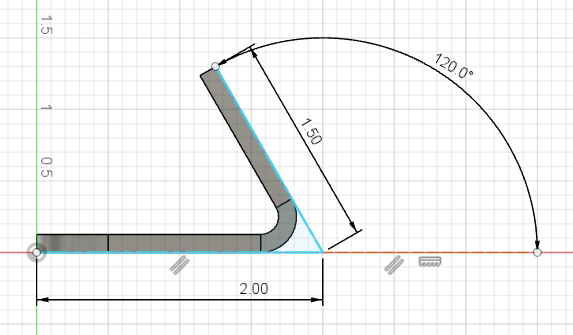

Dimensional tolerances for single bends

At SendCutSend, simple, single flange parts will have a +/- 0.015” dimensional tolerance, bend to edge. This means that a part with one flange may be 0.015” shorter or longer than designed in addition to the applicable cut tolerance for the material.

Check your design using our Bending Calculator to ensure your file is set up using our bend deduction, bend radius, and K factor for the material of your choice. See all bending specifications at a glance in our handy material bending specification table.

Dimensional bending tolerance stackup

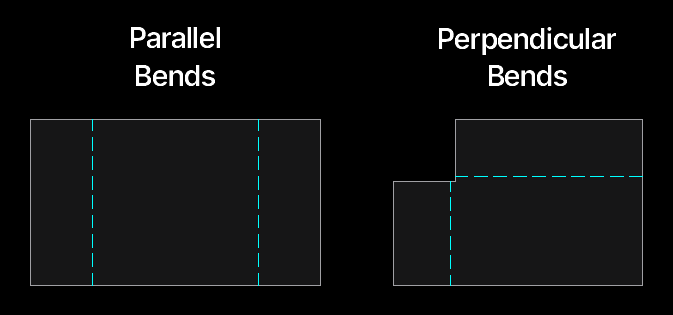

Tolerance stackup occurs when you have multiple parallel bends in a part. For example, a u-channel would be considered two parallel bends.

A part with two perpendicular flanges would not experience tolerance stackup.

Two parallel bends will have a +/- 0.030” dimensional tolerance, bend to edge. Each additional flange adds at least 0.015” tolerance.

Measuring parts accurately

Formed flange lengths should always be measured from the apex or center of the bend. Learn more about flat versus bent dimensions on our Bending Calculator page.

Check out our Bending Design Guidelines and Bending Deformation Guidelines for more information on file setup and what to expect before uploading your part files for an instant quote!