Export your design directly from your CAD software using settings that preserve smooth arcs instead of breaking them into line segments. Fewer nodes means smoother cut edges and better production quality.

Preventing dense nodes or anchor points in your design file results in better edge quality for your parts. Read on for file setup and export tips to reduce node density!

What are nodes?

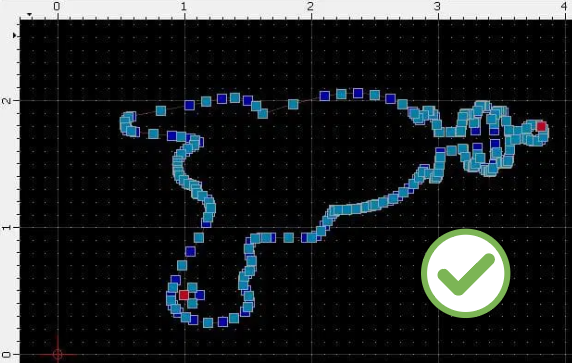

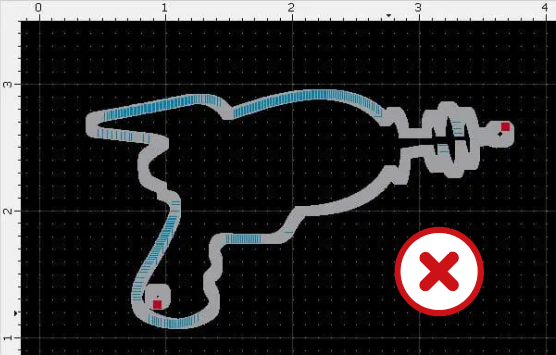

Vector files are made of paths, and the beginning/end of each path is an anchor point or node. Curved paths have nodes along arcs, usually 1–2 per arc.

- Every time the cutting tool reaches a node, it makes a brief stop.

- Fewer nodes = smoother cut edges.

- For CNC routed parts, we need at least .400” between nodes in 2–3 areas for fixture tabs.

Common cause of dense nodes:

- Bad file exports

- Using third-party file converters

- Splines broken into many line segments instead of smooth arcs

How to prevent dense nodes when exporting:

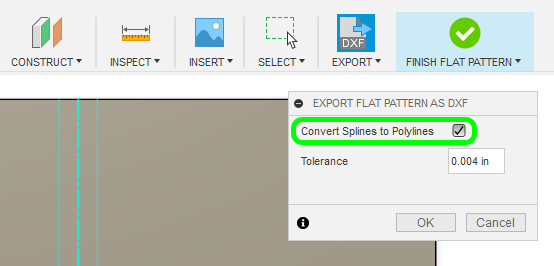

Autodesk Fusion

- Design as a sheet metal part.

- Create a flat pattern → export DXF

- Check Convert splines to polylines before export

Tip: if your part requires bending services, import our Autodesk Fusion sheet metal rules and set up your design with the sheet metal rule for your required material.

SolidWorks

- Use arcs instead of splines when possible

- Try Simplify Spline before export

- In DXF/DWG settings, choose Export all splines as splines

Tip: if your part requires bending services, import our SolidWorks gauge tables and set up your design with the sheet metal rule for your required material.

Rhinoceros 3D

Follow our How to Reduce Nodes in Rhino3D guide

AutoCAD

- In export options, check Export splines as splines

- See our AutoCAD export tutorial for full steps

Adobe Illustrator

- Select your part → Object > Path > Simplify to reduce anchor points

- See our Simplify Complex Paths in Illustrator guide

Inkscape

- Use Simplify (Control + L) to reduce nodes

- See our Inkscape Simplify tool blog post for details

If you already have dense nodes:

- DXF/DWG files: Use free QCAD to redraw circles/arcs

- EPS or other formats: Open in Inkscape or Illustrator and simplify paths

Bottom line:

Preventing dense nodes improves edge quality and saves production time. If we see an issue with your file, we’ll reach out before cutting.

Ask our Support team anytime if you have questions about nodes.