We use tabs to keep your parts from falling out of the parent sheet during laser cutting, waterjet cutting, or CNC routing. You can remove tabs by sanding them off by hand or using a metal file.

Tab and lead-in/out addition is an automatic process, so we’re unable to provide custom tab or lead-in/out placement.

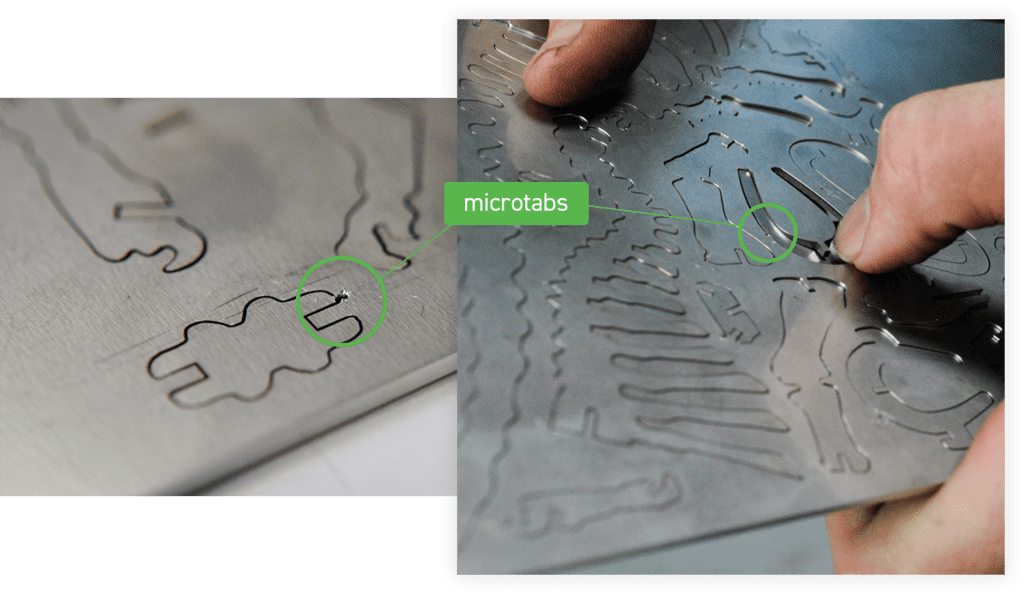

Micro Tabs in Laser and Waterjet Cut Materials

For laser cut and waterjet cut materials, we cut a bit of additional material about 0.010”-0.015” thick on the outside of your parts to create micro tabs. It’s easy enough to break parts out of the sheet by hand but strong enough to hold them in during machining.

Fixture Tabs in CNC Routed Materials

CNC fixture tabs will be a bit larger. We will create a small tab that is approximately .187″ wide, with a depth that is half the material thickness.

Remove tabs by sanding them off by hand or using a metal file. You don’t need to add micro tabs to your design because we automatically do it for you during nesting. We make sure all tabs and lead-ins are outside your part geometry so your design remains true to what you originally sent us. Tab and lead-in/out addition is an automatic process, so we’re unable to provide custom tab or lead-in/out placement.

Finishing Service Considerations

Please note, we do not provide tab removal with parts that have finishing services such as powder coating, so the tabs will be visible through the finish.

In Summary

We use tabs to keep your parts from falling out of the parent sheet during laser cutting, waterjet cutting, or CNC routing.

Remove tabs by sanding them off by hand, or using a metal file. You don’t need to add micro tabs to your design because we automatically do it for you during nesting. We make sure all tabs and lead-ins are outside your part geometry so your design remains true to what you originally sent us.

Tab and lead-in/out addition is an automatic process, so we’re unable to provide custom tab or lead-in/out placement.