Our bend relief requirements depend on the material chosen for your part.

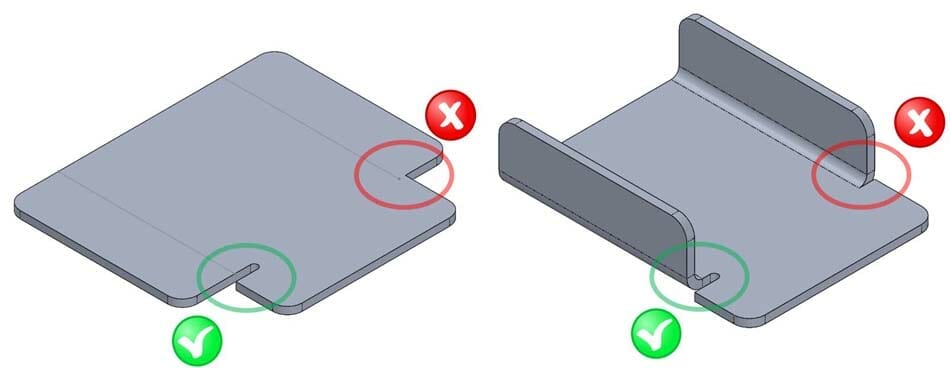

To reduce bulging in the corners of your bent parts and prevent tearing, incorporate bend relief notches into your design. Bend relief notches are just narrow notches or circles put into the corners of your design. These notches should be at least 50% of the material’s thickness in width and the depth should equal to bend radius + material thickness +.020”.

These notches allow for less stress on the inner radii of the flanges, and will help keep the corners of the bends from interfering with the base material. Check out our Bending Deformation Guidelines for more information.

Sheet metal requirements are more flexible than polycarbonate or plastic bending. Read on to learn how to verify minimum specs and measure your parts!

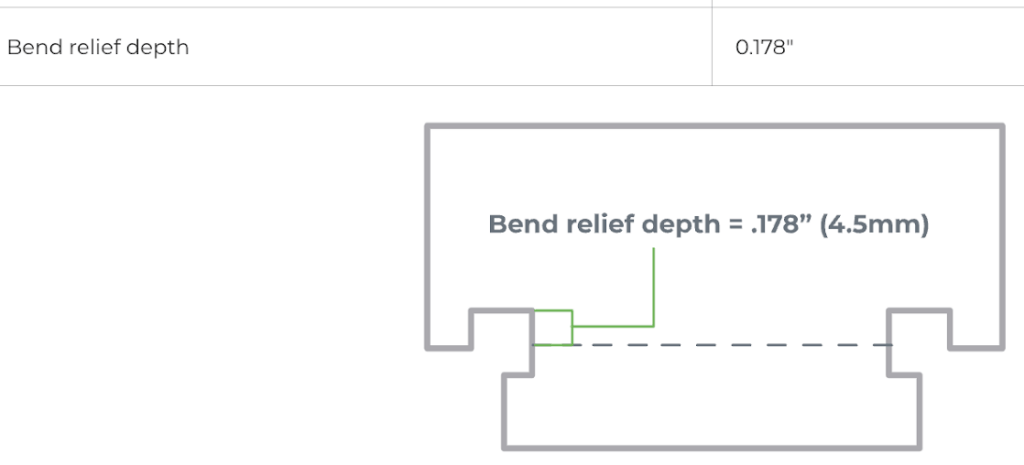

Polycarbonate bend relief requirements

Bend reliefs in polycarbonate parts must have a rectangular shape and meet the minimum bend relief depth required. Otherwise the parts will crack.

Find the bend relief depth required for each sheet thickness on our polycarbonate material page.

Learn more about polycarbonate bending requirements.

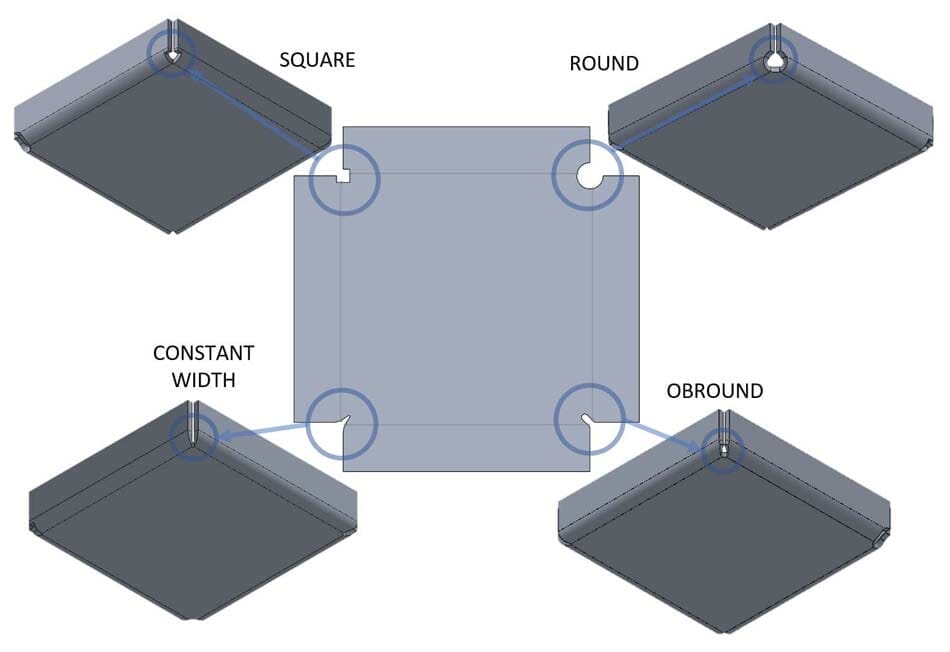

Sheet metal bend relief requirements

For sheet metal parts, we recommend adding bend reliefs for the best possible outcome – especially for parts in materials 0.187” and thicker.

Thinner materials may be producible without reliefs but tearing and distortion in corners may impact end use of your parts.

You’re welcome to use the relief shape you prefer on sheet metal parts!

Measuring bend reliefs

On the flat pattern for your design, measure from the bend line (center of the bend) to the bottom of the relief. The measured distance should be at least our minimum bend relief depth for the material thickness you plan to use.

Consider moving the bend location

Instead of adding a relief feature, you can simply move the bend to a location where it will no longer require a relief. This won’t work for all parts but it’s a great solution for many!

Feeling relieved?

While there is some flexibility with our sheet metal bend relief requirements, it’s critical that polycarbonate parts meet relief specifications. Be sure to review our complete bending guidelines before uploading your part file to our website for an instant quote. If you have questions just ask our Support team!